Polystyrene foam tape for automobiles

A styrofoam and foaming technology, used in adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of excessive VOC volatilization, reduced adhesion, loss of viscosity, etc. Lightweight, improved resilience and impact resistance, easy die-cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

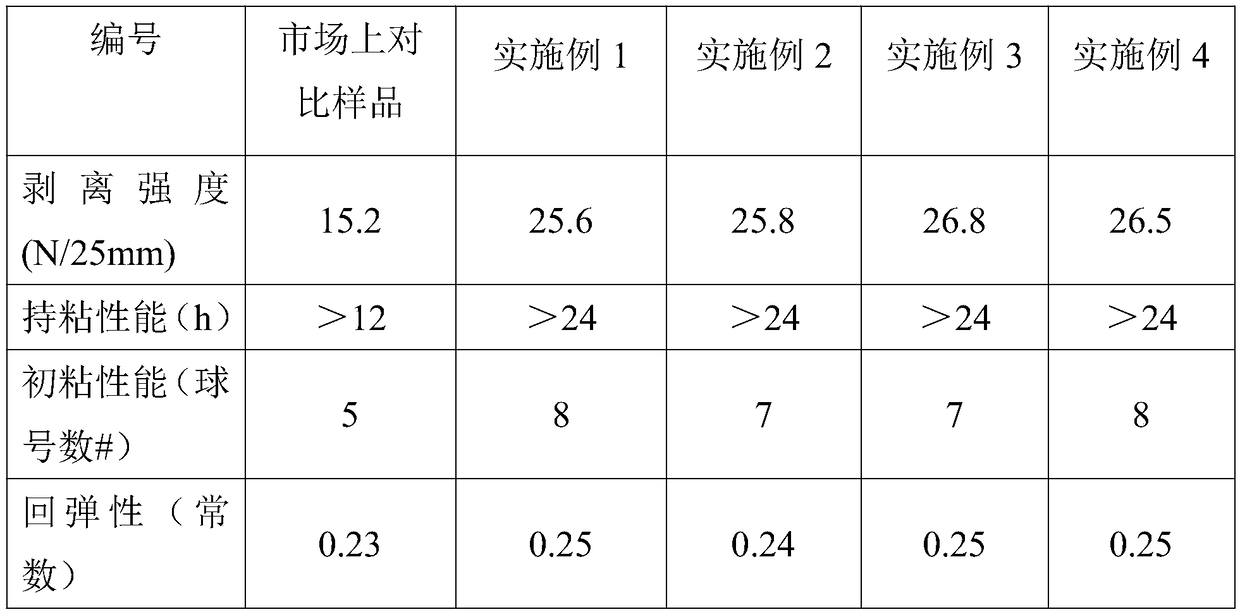

Embodiment 1

[0033] Prepare polyacrylate styrofoam according to the following raw materials in parts by weight: 80 parts of butyl acrylate, 20 parts of methyl methacrylate, 5 parts of rubber elastic body, 0.8 part of sodium laurylsulfonate emulsifier, buffer carbonic acid 0.2 part of sodium hydrogen, 1 part of blowing agent n-pentane, 5 parts of aziridine crosslinking agent. Wherein the rubber elastic body can be the emulsion of natural rubber, modified natural rubber or styrene-butadiene rubber, and the rubber can be used alone or in combination.

[0034] The preparation method of polyacrylate styrofoam is as follows:

[0035] S1. Add water, butyl acrylate, methyl methacrylate, rubber elastomer and 20% to 30% compound emulsifier into the first reaction vessel, stir and heat up to 80° C. within 30 minutes;

[0036] S2. Add water and the rest of the composite emulsifier to the second reaction vessel under nitrogen protection, stir and heat up to 85° C., and add the initiator ammonium persu...

Embodiment 2

[0046] Prepare polyacrylate styrofoam with the following raw materials in parts by weight: 70 parts of ethyl acrylate, 25 parts of a mixture of methyl methacrylate and vinyl acetate as the hard monomer, 8 parts of polyurethane elastomer, dodecyl sulfonate 1 part of composite emulsifier of sodium laurate and potassium lauricate, 0.2 part of buffering agent sodium bicarbonate, 0.8 part of foaming agent n-hexane, 6 parts of polycarbodiimide crosslinking agent.

[0047] The preparation method of polyacrylate styrofoam is as follows:

[0048] S1. Add water, ethyl acrylate, methyl methacrylate, vinyl acetate mixture, polyurethane elastomer and 20% to 30% compound emulsifier into the first reaction vessel, stir and heat up to 85° C. within 30 minutes;

[0049] S2. Add water and the rest of the composite emulsifier to the second reaction vessel under nitrogen protection, stir and heat up to 90°C, and add the initiator ammonium persulfate;

[0050]S3. Drop the materials in the first r...

Embodiment 3

[0059] Prepare polyacrylate styrofoam according to the following raw materials in parts by weight: the soft elastomer is 80 parts of a mixture of butyl acrylate and ethyl acrylate, 22 parts of vinyl acetate, 8 parts of silicone elastomer, dodecyl sulfonic acid 0.5 parts of composite emulsifier of sodium and potassium stearate, 0.2 parts of buffering agent sodium bicarbonate, 1 part of foaming agent n-heptane, and 8 parts of aziridine crosslinking agent.

[0060] The preparation method of polyacrylate styrofoam is as follows:

[0061] S1. Add water, a mixture of butyl acrylate, ethyl acrylate and vinyl acetate, silicone elastomer and 20% to 30% compound emulsifier into the first reaction vessel, stir and heat up to 80° C. within 30 minutes;

[0062] S2. Add water and the rest of the composite emulsifier to the second reaction vessel under nitrogen protection, stir and heat up to 90°C, and add the initiator ammonium persulfate;

[0063] S3. Drop the materials in the first react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com