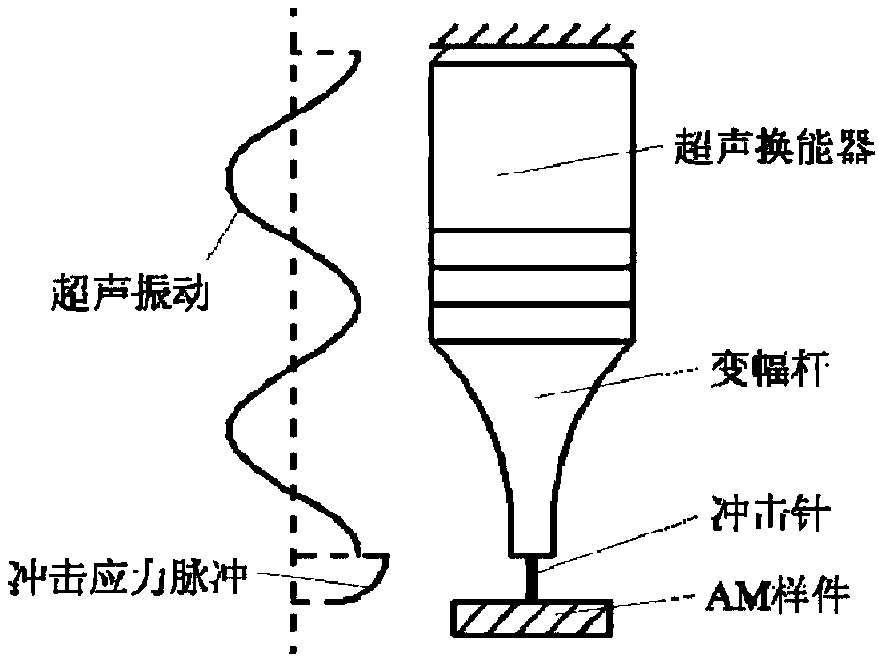

Method for estimating the depth of a metal additive manufacturing ultrasonic impact treatment action layer

An ultrasonic impact and metal additive technology, which is applied in the field of estimating the depth of the action layer of metal additive manufacturing by ultrasonic impact treatment, and the depth of the action layer of ultrasonic impact treatment, can solve the problems of inconvenient use process, high testing cost, and cumbersome sample preparation. , to achieve the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

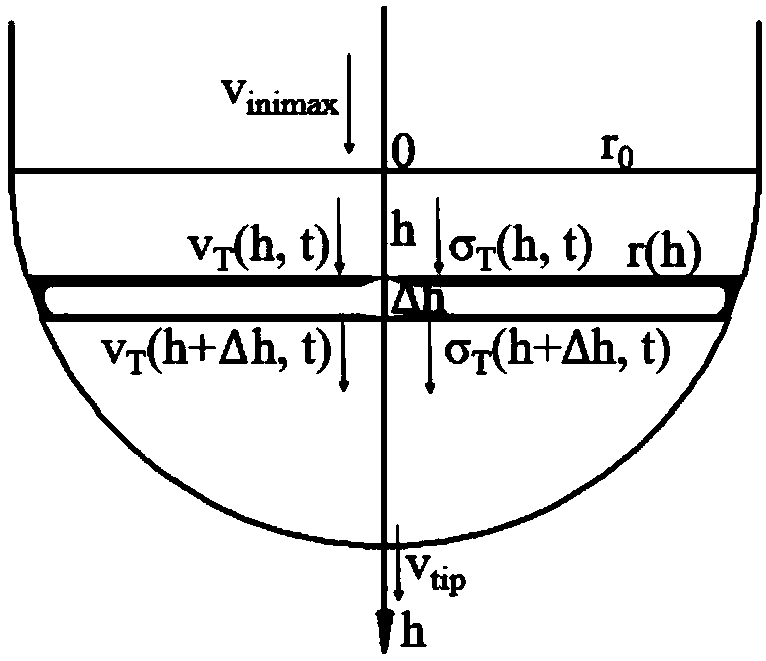

Method used

Image

Examples

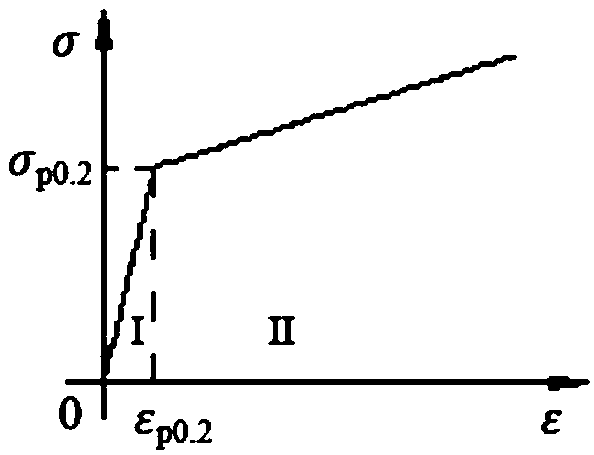

specific Embodiment 1

[0080] A 316L stainless steel sample (LMD-deposited 316LSS) was prepared by laser metal deposition (LMD), and the subsequent ultrasonic impact treatment (UIT) experiment was used to verify the correctness of the plastic zone depth calculation model. Ultrasonic impact test parameters are: ultrasonic frequency 20kHz, horn amplitude 80μm, impact needle radius 2.6mm. The impact needle uses high-strength steel, and its density and elastic modulus are 7.85g / cm 3 and 205GPa. From formula (15a), in order to calculate the depth of the action layer, the parameters of the material to be impacted are density, elastic modulus, Poisson's ratio and yield strength of the material under high strain rate conditions. The density of LMD-deposited 316L SS measured by drainage method is 7.75g / cm 3 . The elastic modulus and Poisson's ratio can be measured by ultrasonic method, and their values are 200GPa and 0.3 respectively. Considering that the microstructure and properties of LMD forming ma...

specific Embodiment 2

[0090] 304 stainless steel was prepared by laser metal deposition technology, followed by ultrasonic impact treatment (UIT) experiments. The ultrasonic frequency is 20kHz, the amplitude of the horn is 80μm, and the radius of the impact needle is 2.6mm. The impact needle uses high-strength steel, and its density and elastic modulus are 7.85g / cm 3 and 205GPa. Laser deposition 304 stainless steel material parameters are: density 7.80g / cm 3 , the elastic modulus and Poisson's ratio are 201GPa and 0.3 respectively, and the dynamic constitutive relation is:

[0091]

[0092] Therefore, the compressive yield strength in the UIT process is 300MPa. Substituting the above experimental parameters and material parameters into the calculation model of the depth of the action zone (Equation 15a), the depth of the action layer can be obtained: r max = 1.41 mm. The microhardness distribution test is also used, and the actual depth of the active zone is measured to be 1.60mm. The resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com