Super-hydrophobic icing prevention coating with active photothermal deicing function, coating layer, preparation method of coating and application of coating

An active light, super-hydrophobic technology, applied in coatings and other directions, can solve the problems of rough structure damage, difficult to apply in large areas, single function, etc., to achieve the effect of prolonging the freezing time, easy to control, and ordinary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

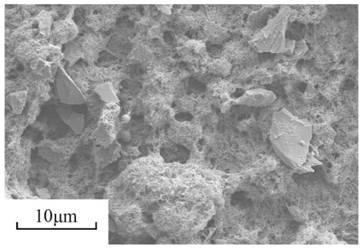

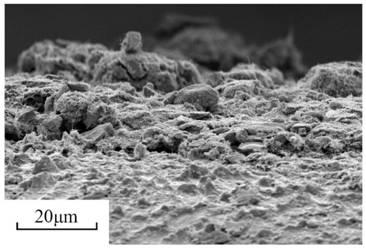

[0033] Weigh 20 mg of carboxylated multi-walled carbon nanotubes (CNTs, produced by Nanjing Xianfeng Nano Material Technology Co., Ltd., average diameter: 100 nm, length: 10-20 microns, purity: 95%), silicon carbide micropowder (SiC, Shandong Jin Produced by Mengxin Material Co., Ltd., 2000 mesh, purity: 95%), 10 mg was added to 100 ml of absolute ethanol, and 2 ml of ethyl orthosilicate (produced by Shanghai Macklin Biochemical Co., Ltd., purity: 98%) was measured. 100 microliters of perfluorodecyltrimethoxysilane (manufactured by Shanghai Macklin Biochemical Co., Ltd., purity: 97%) was added to the above-mentioned absolute ethanol, and ultrasonically dispersed for 30 minutes to obtain a suspension, that is, a coating.

[0034] Use acetic acid-vinyl ester (EVA, produced by Arkema, France, brand EMB 01027A) as the substrate, and ultrasonically clean it for 30 minutes; The obtained suspension (i.e. coating) is vertically sprayed on the EVA substrate, and it is naturally dried a...

Embodiment 2

[0039] Take by weighing 20 milligrams of carboxylated multi-walled carbon nanotubes (same as Example 1), 40 milligrams of silicon carbide micropowder, join in 100 milliliters of absolute ethanol, measure 2 milliliters of ethyl orthosilicate, perfluorodecyltrimethoxy Add 100 microliters of silane into the above-mentioned absolute ethanol, and disperse it ultrasonically for 30 minutes to obtain a suspension, that is, a coating.

[0040] Adopt acetic acid-vinyl ester (EVA, with embodiment 1) as base material, ultrasonic cleaning 30min, with spray gun (same embodiment 1) the suspension liquid that makes is vertically sprayed on EVA substrate, under room temperature, air dry , the distance between the nozzle and the EVA substrate is 15cm, and a superhydrophobic anti-icing coating that can be used for active photothermal deicing can be obtained on the EVA surface.

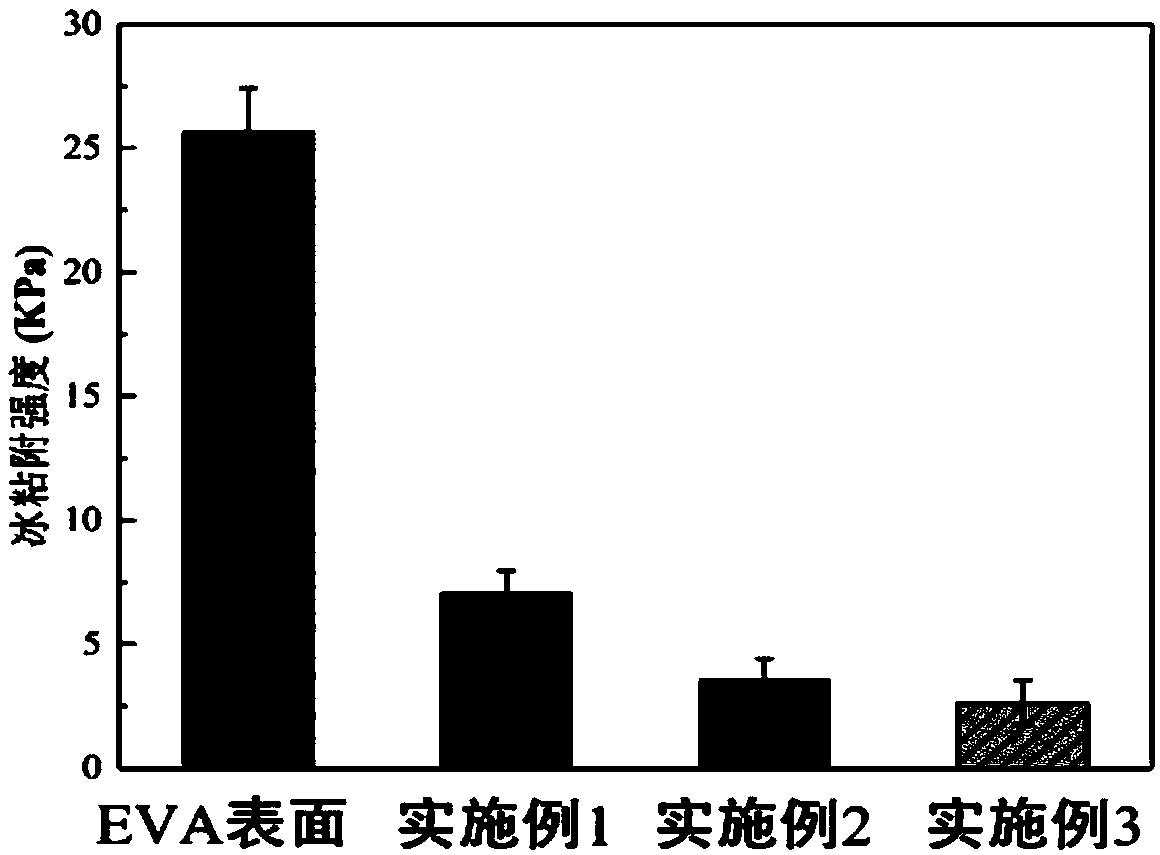

[0041] The superhydrophobicity, anti-icing performance and photothermal performance test data of the functional coatin...

Embodiment 3

[0045] Take by weighing 20 milligrams of carboxylated multi-walled carbon nanotubes (same as Example 1), 100 milligrams of silicon carbide micropowder, join in 100 milliliters of absolute ethanol, measure 2 milliliters of ethyl orthosilicate, perfluorodecyltrimethoxy Add 100 microliters of silane into the above-mentioned absolute ethanol, and disperse it ultrasonically for 30 minutes to obtain a suspension, that is, a coating.

[0046] Adopt acetic acid-vinyl ester (EVA, with embodiment 1) as base material, ultrasonic cleaning 30min, with spray gun (same embodiment 1) the suspension liquid that makes is vertically sprayed on EVA substrate, under room temperature, air dry , the distance between the nozzle and the EVA substrate is 15cm, and a superhydrophobic anti-icing coating that can be used for active photothermal deicing can be obtained on the EVA surface.

[0047] The superhydrophobicity, anti-icing performance and photothermal performance test data of the functional coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com