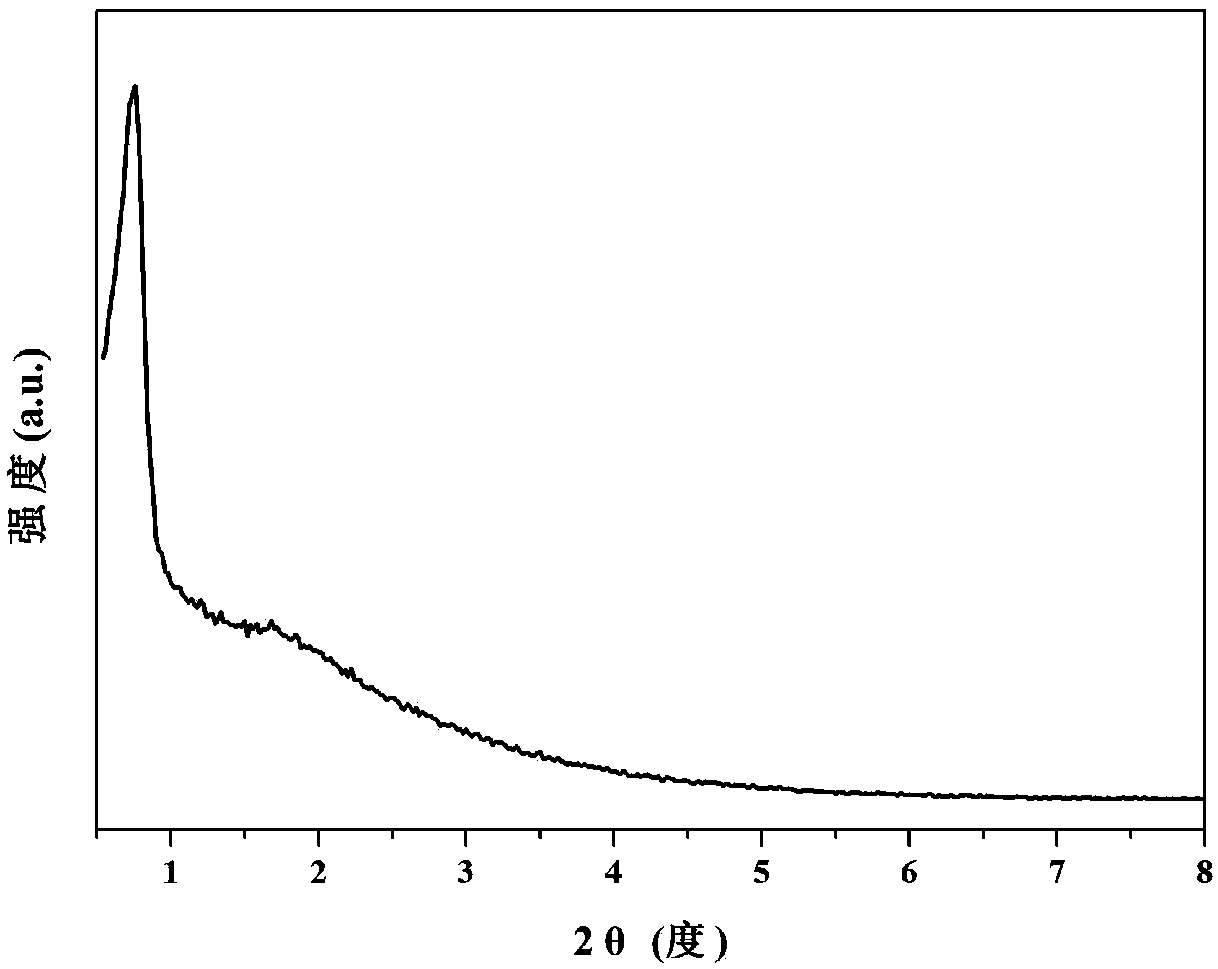

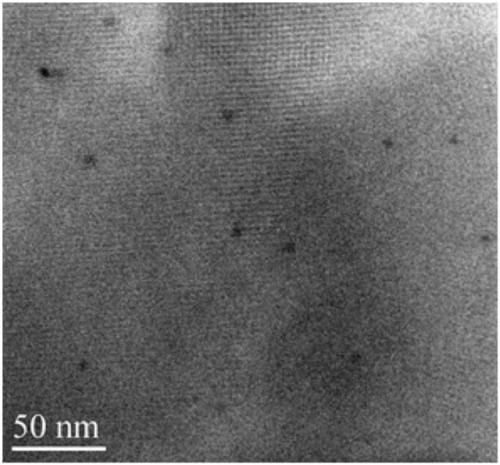

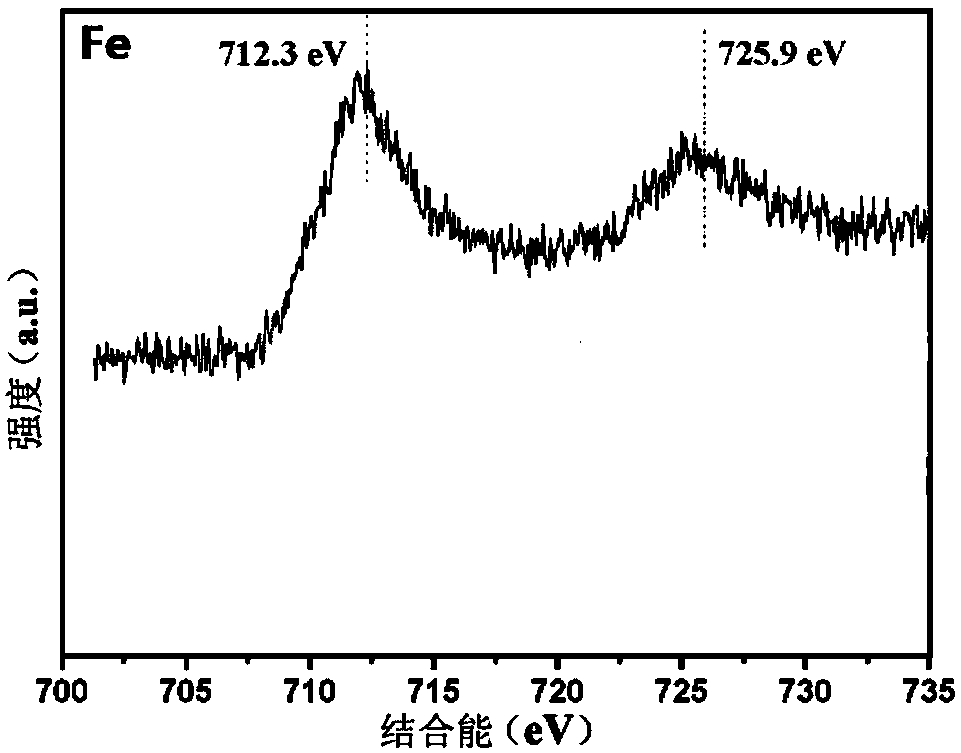

Nano-iron modified SBA-16 molecular sieve and preparation method and application thereof

A molecular sieve and nano-iron technology, which is applied in the field of molecular sieves, can solve the problems of metal particle agglomeration, molecular sieve channel blockage, specific surface area decrease, etc., and achieve the effect of large specific surface area and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] At 60°C, 3.2g F127(EO 106 PO 70 EO 106 ) and 70g of deionized water were added to the reactor in turn, stirred evenly, and then 50mL of 0.1mol / L hydrochloric acid solution was added, and after fully stirring until uniform, the complexation of 0.7g of ferrous chloride and 3.2g of ethylenediaminetetraacetic acid was added Continue to stir, slowly add 11g tetraethyl orthosilicate (TEOS) dropwise, and finally add 15g ethanol, the molar ratio of the obtained mixture is SiO 2 :73H 2 O:0.005R:0.1Fe:0.09H + , the mixture was transferred to a crystallization kettle, heated to 110° C., and crystallized at a constant temperature for 72 hours. After the crystallization is complete, when the temperature drops to room temperature, the reacted mixture is separated, washed, and dried at 110°C, and the dried sample is transferred to a muffle furnace for 4 hours at 500°C. , to obtain Fe-SBA-16 molecular sieve powder. Place the original powder of Fe-SBA-16 molecular sieve at the bot...

Embodiment 2

[0046] Same as Example 1, the difference is that the consumption of F127 is changed into 4.9g, the amount of deionized water is changed into 100g, the amount of hydrochloric acid is changed into 80mL, the iron source is changed into ferrous nitrate, and the consumption is 1.08g, B The amount of diamine tetraacetic acid is changed into 6.6g, silicon source is changed into silica sol (SW-25, silicon dioxide content is 25wt%), consumption is 9.6g, alcohol is changed into ethylene glycol, consumption is 23g, the mixture obtained The molar ratio of SiO 2 :139H 2 O:0.009R:0.15Fe:0.2H + , the crystallization temperature is 90°C, the crystallization time is 60h, the drying temperature is 120°C, the roasting temperature is 550°C, the roasting time is 5h, the hydrogen heating rate is changed to 4°C / min, the reduction temperature is changed to 500°C, and the reduction time Change it to 3h, keep the other components and synthesis conditions unchanged, and obtain nano-iron modified SBA-1...

Embodiment 3

[0049] Same as Example 1, the difference is that the organic template agent is changed to F108, the dosage is 3.7g, the amount of deionized water is changed to 80.6g, the acid is changed to nitric acid, the dosage is 90mL, and the iron source is changed to ferrocyanide Potassium chloride, the consumption is 3.6g, the silicon source is changed into sodium silicate, the consumption is 12.1g, the amount of ethanol is changed into 7.6g, the molar ratio of the mixture obtained is SiO 2 :104H 2 O:0.006R:0.2Fe:0.21H + , the crystallization temperature is 100°C, the crystallization time is 54h, the drying temperature is changed to 130°C, the roasting temperature is changed to 600°C, the roasting time is changed to 6h, the heating rate of hydrogen reduction is changed to 5°C / min, and the reduction temperature is changed to 550 ℃, the reduction time was changed to 4h, and the other components and synthesis conditions were unchanged, and the SBA-16 molecular sieve decorated with nano-ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com