Method for repairing flaws of titanium-aluminum intermetallic compound castings

A technology for intermetallic compounds and casting defects. It is applied in the field of repairing titanium-aluminum intermetallic compound casting defects. It can solve the problems of difficult parts repair operations, poor atmosphere protection conditions, and inability to use casting defects, etc., to achieve slow heat loss and cooling. Slow to avoid the effect of repairing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

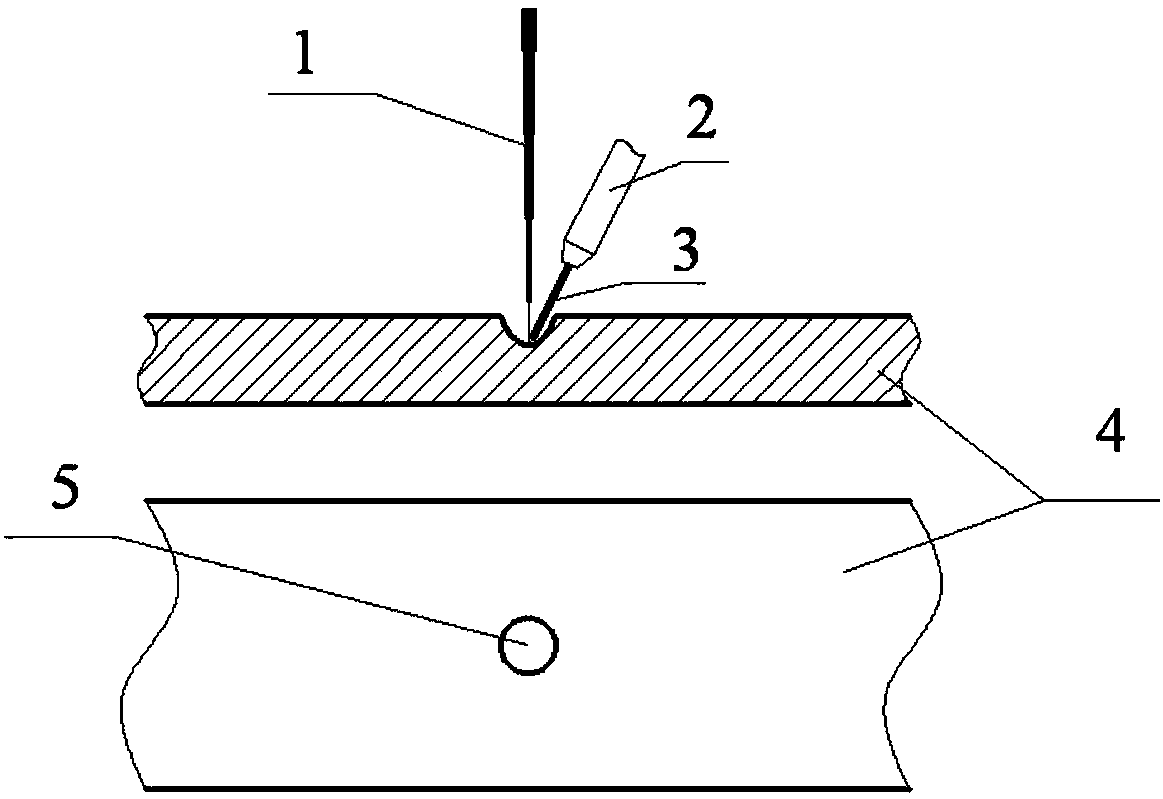

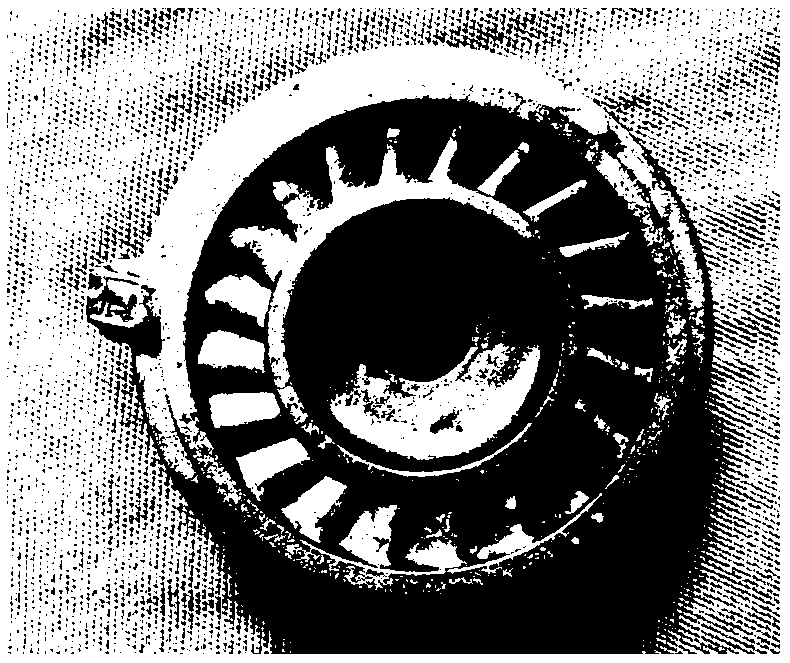

[0039] figure 2 Shown is a titanium-aluminum intermetallic compound (Ti-48Al-2Cr-2Nb) vortex casting. After the casting is hot isostatically pressed, the closure of internal looseness and other defects leads to surface pit defects. The pit defect size is 3mm and the depth is 2mm.

[0040] The casting was repaired by electron beam fuse deposition repair method. The specific steps are:

[0041] The surface of the pit defect of the vortex generator is mechanically polished to reveal a metallic luster. After polishing, the size of the area to be repaired is 5mm in diameter on the upper surface, 2.5mm in depth, and a circular arc transition on the bottom surface;

[0042]Ti-48Al-2Cr-2Nb filaments with the same composition and a diameter of 1.0 mm are used as filling materials. The wire is connected to a TA0 pure titanium wire with a diameter of 1.0mm to form a complete wire by resistance welding, and only the part of the Ti-48Al-2Cr-2Nb wire is used for repair. The wire is vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com