Linear coreless winding, preparation technology and linear permanent magnet motor with winding

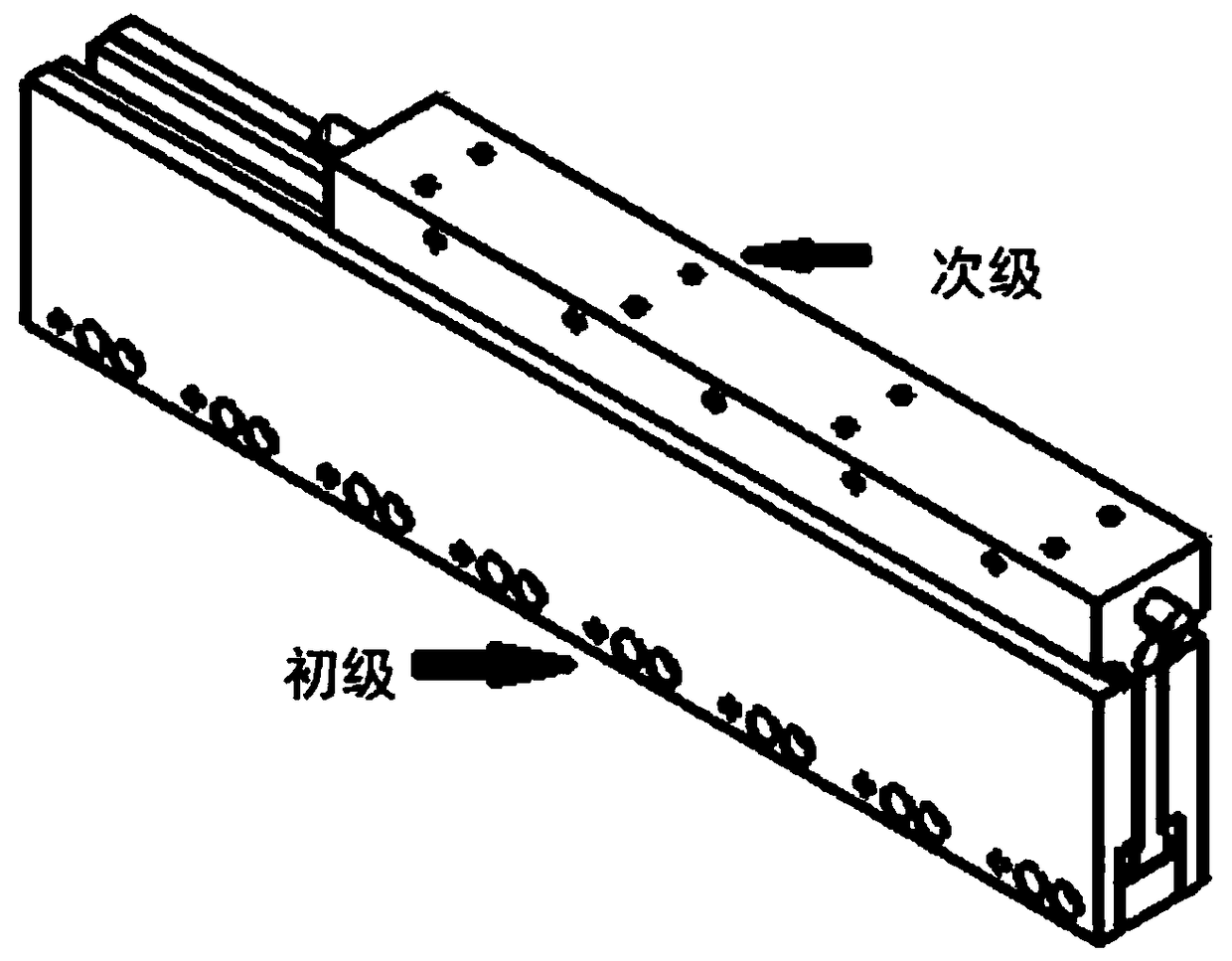

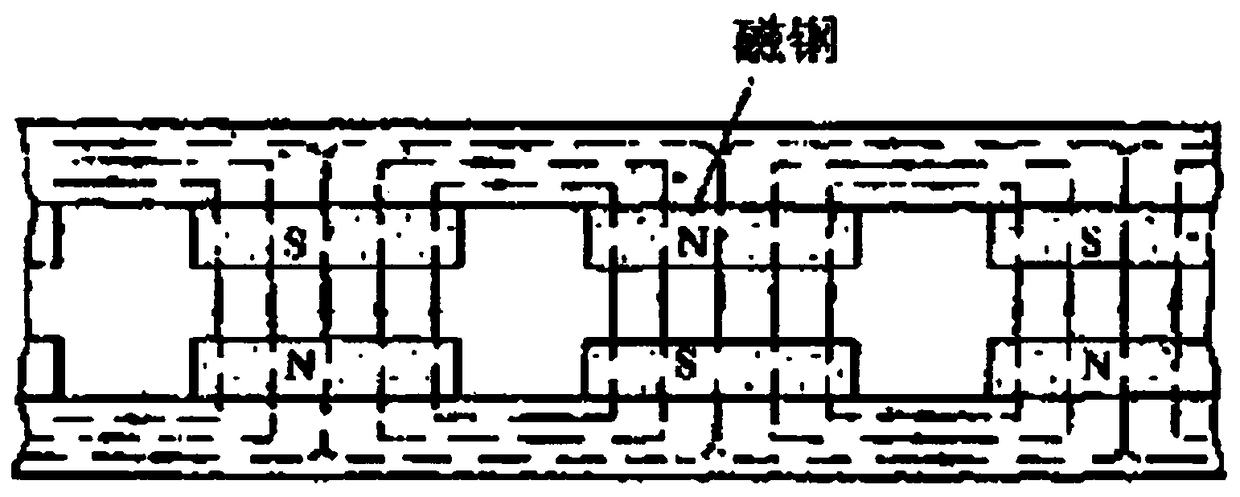

A technology of linear motor and preparation process, which is applied in the field of ironless winding, which can solve the problems of increased resistance and electric density, increased copper consumption, and high noise, and achieves reduced weight and volume, increased proportion of copper cross-section, and improved power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

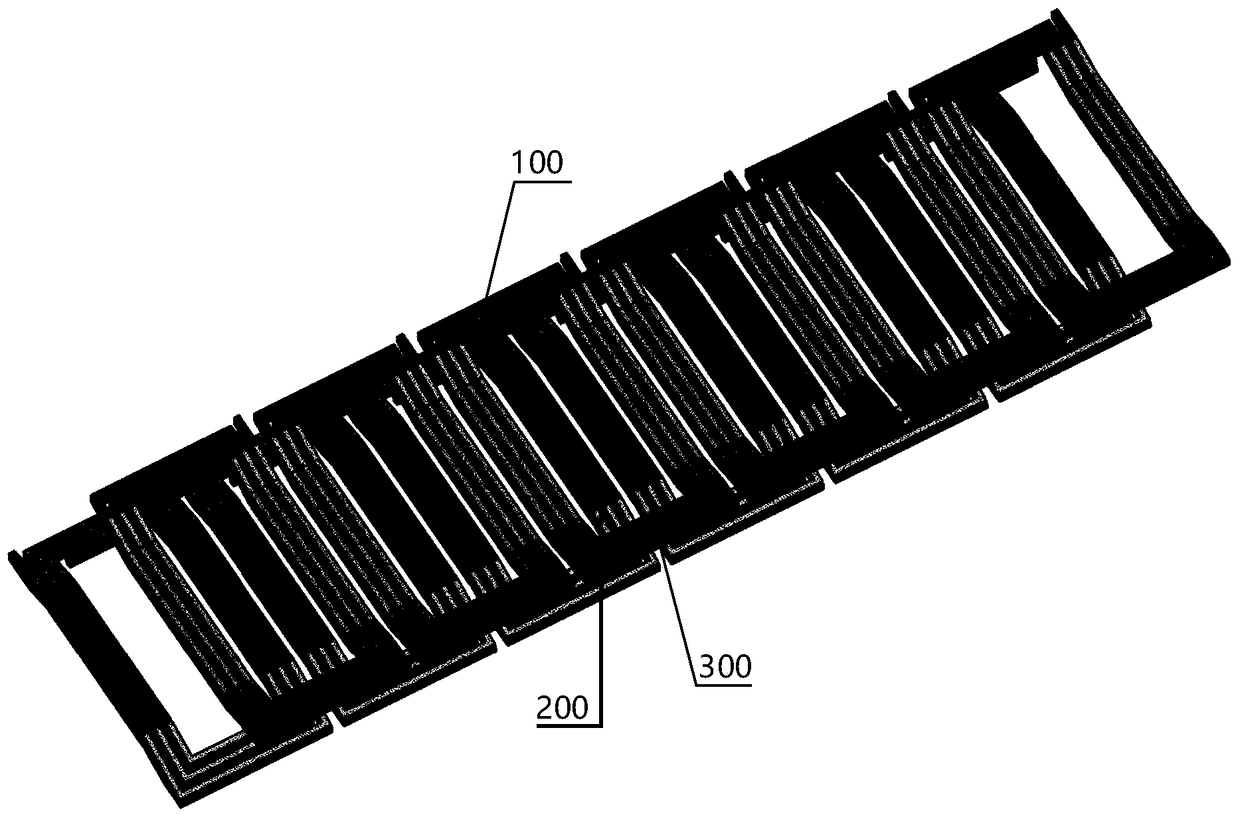

[0067] Embodiment 1: copper plate cutting process

[0068] Figure 8 The processing flow of the copper plate cutting method is shown: (1) Cut the thin copper plate into the rectangular module shown in the figure; (2) Use the mold to press the rectangular module obtained in step (1) into the shape shown in the figure. If the concentrated winding method is used, it can be This step is omitted; (3) Using wire cutting and other precision processing methods, the copper plate is cut along the normal direction into a coil formed by winding concentric strip-shaped copper sheets; (4) The coils are alternately stacked and arranged to form a straight line Type winding structure, and use fixtures to shape the arranged winding modules, and dip paint for inter-turn insulation treatment; (5) Winding installation, positioning, wiring; (6) Use epoxy resin or other non-metallic materials with high thermal conductivity , the secondary winding is integrally potted and molded.

[0069] In this m...

Embodiment 2

[0070] Example 2: Foil winding processing

[0071] The foil winding processing flow includes the following steps: (1) as Figure 9 As shown, the strip-shaped copper foil is wound into a rectangle, and the coiled strip can be divided into two schemes, among which scheme 1 adopts the pure copper foil wound into a rectangular structure as shown in the figure; scheme 2 adopts copper foil + insulation Winding in the form of paper, this scheme can be insulated at the same time during the winding process; (2) if Figure 10As shown, after winding and forming, the cross-section of coil AA' is rectangular, and the winding module can be obtained after cutting off the gray part; (3) The coil of Scheme 1 needs to be unrolled, dipped in paint, and then re-wound to shape, and in Scheme 2, due to the existing Insulating paper only needs to be dipped in varnish as a whole for insulation treatment; (4) winding installation, positioning, and wiring; (5) use epoxy resin or other non-metallic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com