A kind of carbon-based catalyst using biomass cotton and its preparation method and application

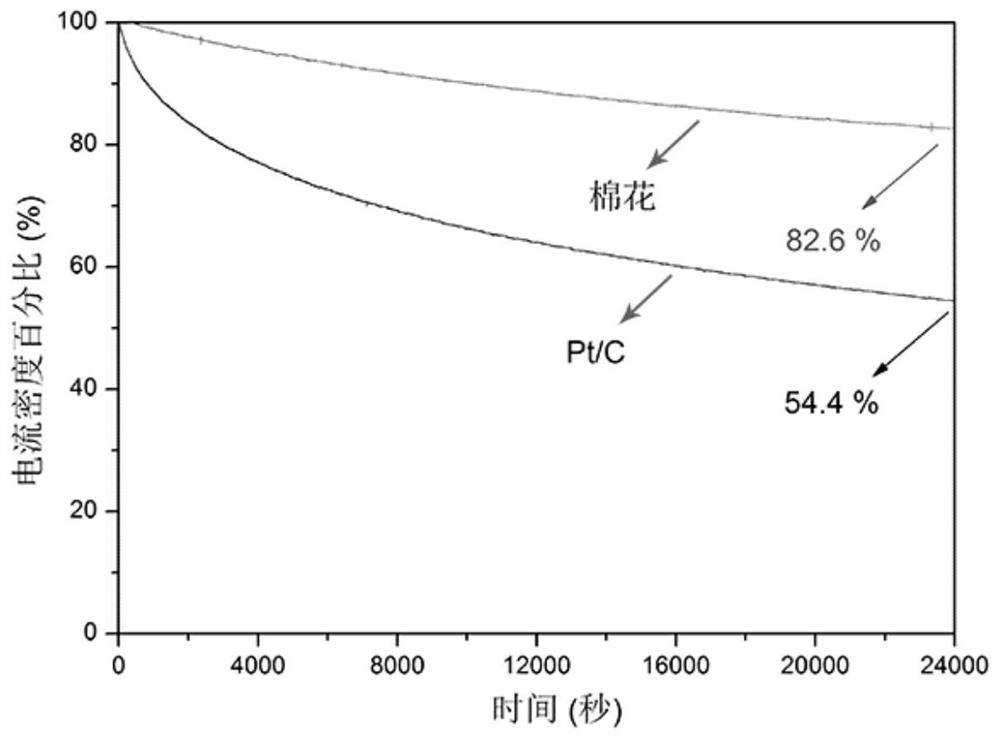

A catalyst and biomass technology, which is applied in the field of biomass cotton as carbon-based catalyst and its preparation, can solve the problems of poor effect of soaking and absorbing solution, affecting catalytic activity, and poor doping effect, and achieves environmental friendliness and responsiveness. The effect of short time and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

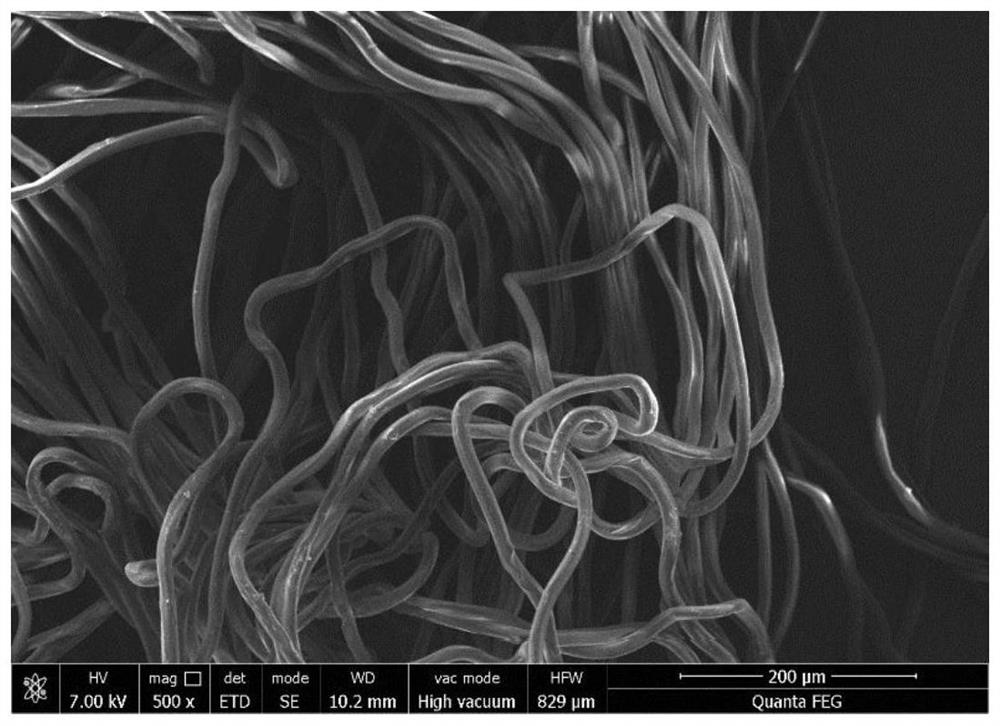

[0066] (1) Take 24g of cotton, put it into an airtight container containing a mixed solution of deionized water and ethanol (ratio 1:1), heat it in an oven at 100°C for 2 hours, and after cooling to room temperature, take out the cotton and put it in drying in an oven;

[0067] (2) Take by weighing ferric chloride 5.4g, cobalt chloride 3.1g, polym-phenylenediamine 1.2g, hydroxylamine chloride 3.4g and be mixed with uniform mixed solution;

[0068] (3) Weigh the dried cotton of step (1) and immerse it in the mixed solution in step (2), then put it into a lyophilizer, and freeze and dry it in a vacuum for 48 hours;

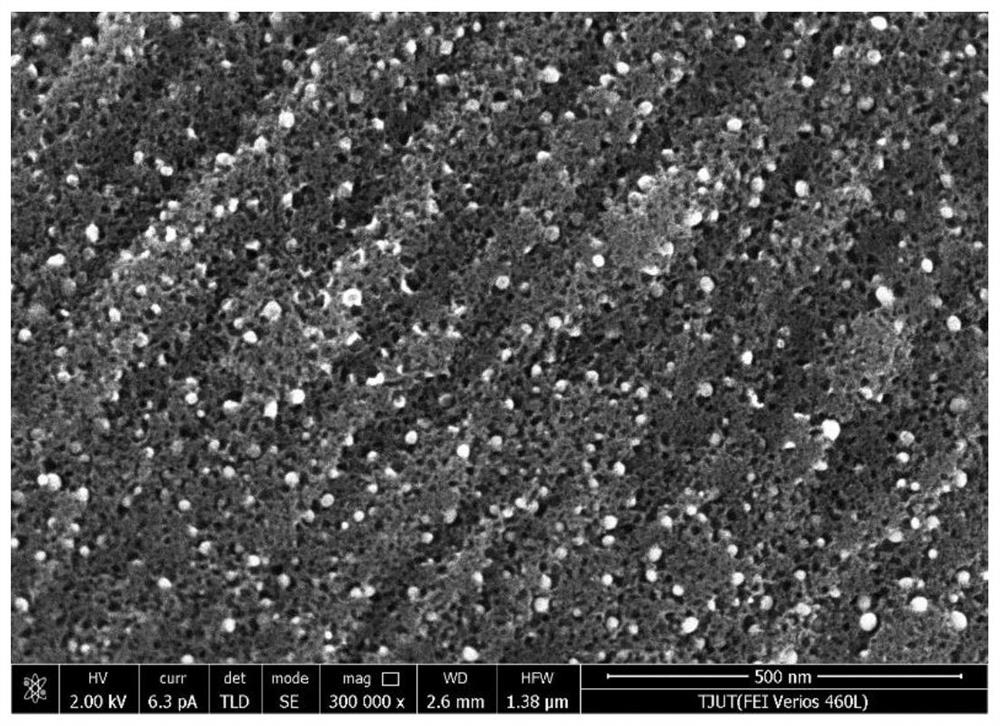

[0069] (4) Put the freeze-dried cotton in step (3) into a porcelain boat, and place it under inert N 2 In an air atmosphere, calcine at 1200°C for 0.5 hours in a microwave oven for 30 minutes, where ammonia gas is introduced at 500°C for 5 minutes, and then cooled to room temperature;

[0070] (5) Take the product in step (4) out of the tube furnace, perform ball ...

Embodiment 2

[0076] (1) Take 24g of cotton, put it into a closed container containing 10 times the amount of deionized water and ethanol mixed solution (ratio 1:1), heat it in an oven at 80°C for 5 hours, and take out the cotton after cooling to room temperature , put into the oven to dry;

[0077] (2) Take by weighing ferric chloride 5.4g, cobalt chloride 3.1g, polym-phenylenediamine 1.2g, hydroxylamine chloride 3.4g and be mixed with uniform mixed solution;

[0078] (3) Weigh the dried cotton of step (1) and immerse it in the mixed solution in step (2), then put it into a lyophilizer, and freeze and dry it in vacuum for 36 hours;

[0079] (4) Put the freeze-dried cotton in step (3) into a porcelain boat, and in an inert argon atmosphere, heat it up to calcination at 1000°C for 1 hour in a microwave oven in an inert argon atmosphere. Ammonia for 10 minutes, then cooled to room temperature;

[0080] (5) Take the product in step (4) out of the tube furnace, perform ball milling for 20 min...

Embodiment 3

[0085](1) Take 24g of cotton, put it into an airtight container containing 5 times the mixed solution of deionized water and ethanol (ratio 2:1), heat it in an oven at 100°C for 2 hours, and take out the cotton after cooling to room temperature , put into the oven to dry;

[0086] (2) Take by weighing ferric chloride 5.4g, cobalt chloride 3.1g, polym-phenylenediamine 1.2g, hydroxylamine chloride 3.4g and be mixed with uniform mixed solution;

[0087] (3) Weigh the dried cotton of step (1) and immerse it in the mixed solution in step (2), then put it into a lyophilizer, and freeze and dry it in vacuum for 72 hours;

[0088] (4) Put the freeze-dried cotton in step (3) into a porcelain boat, and in an inert N2 gas atmosphere, rise to calcination at 1200° C. for 0.1 hour in a microwave oven for 40 minutes, wherein at 600° C. Ammonia for 5 minutes, then cooled to room temperature;

[0089] (5) Take the product in step (4) out of the tube furnace, perform ball milling for 40 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com