A solar cell light attenuation machine

A technology of solar cells and light attenuation machines, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of uneven light source irradiation, low space utilization rate, and small number of cells, so as to achieve uniform light source irradiation and space utilization High efficiency and good installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

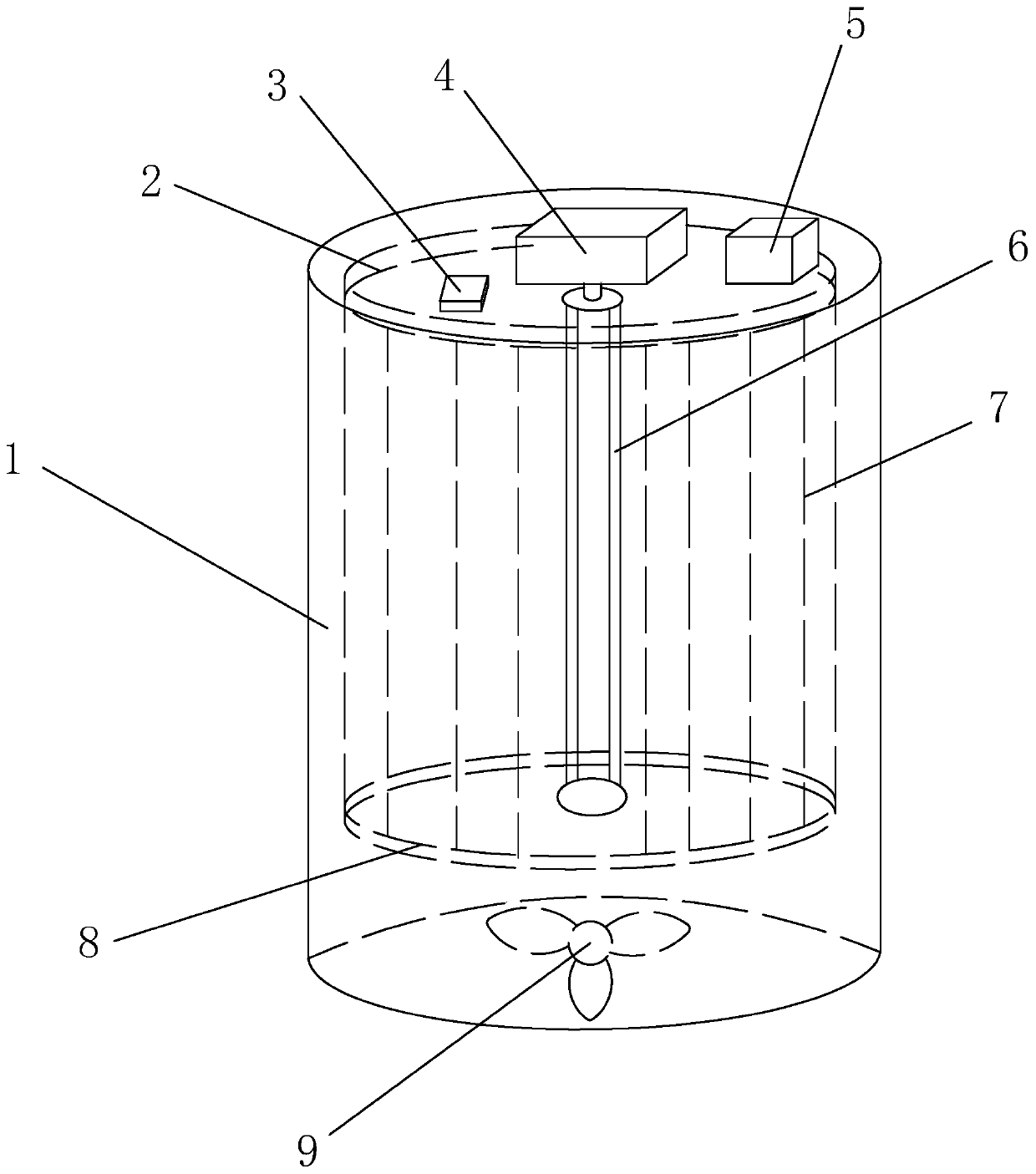

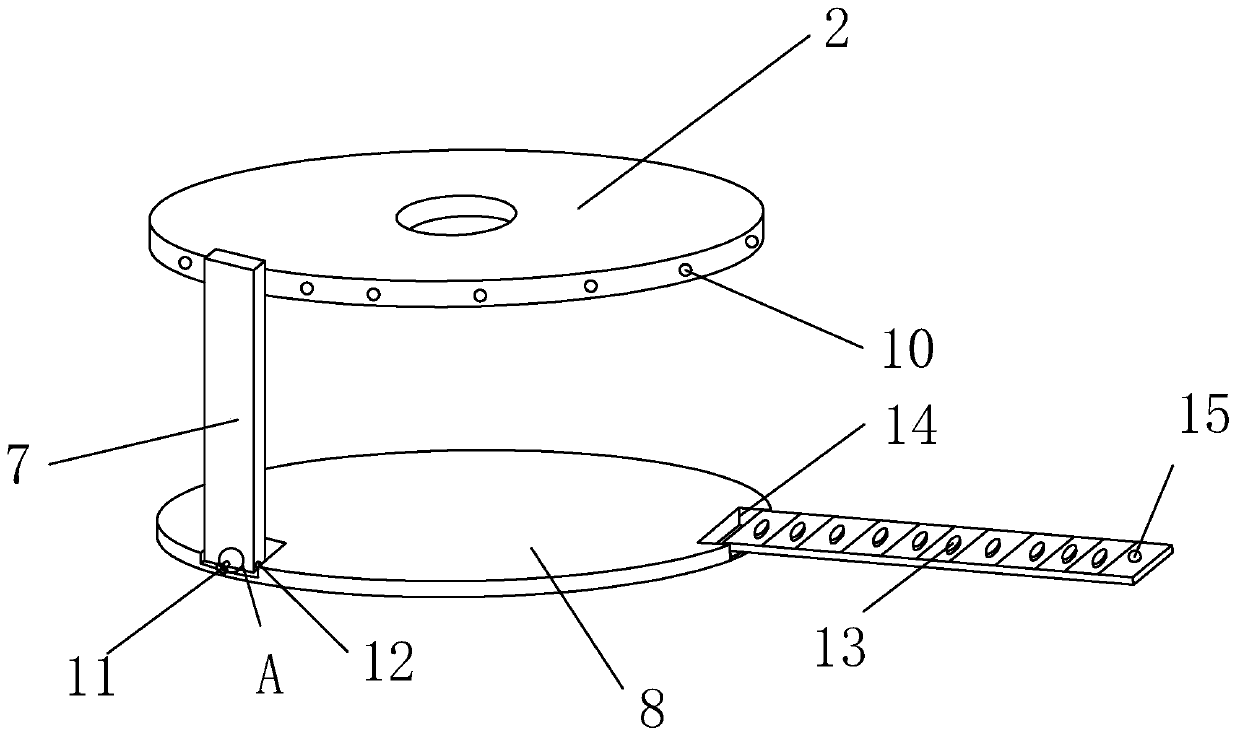

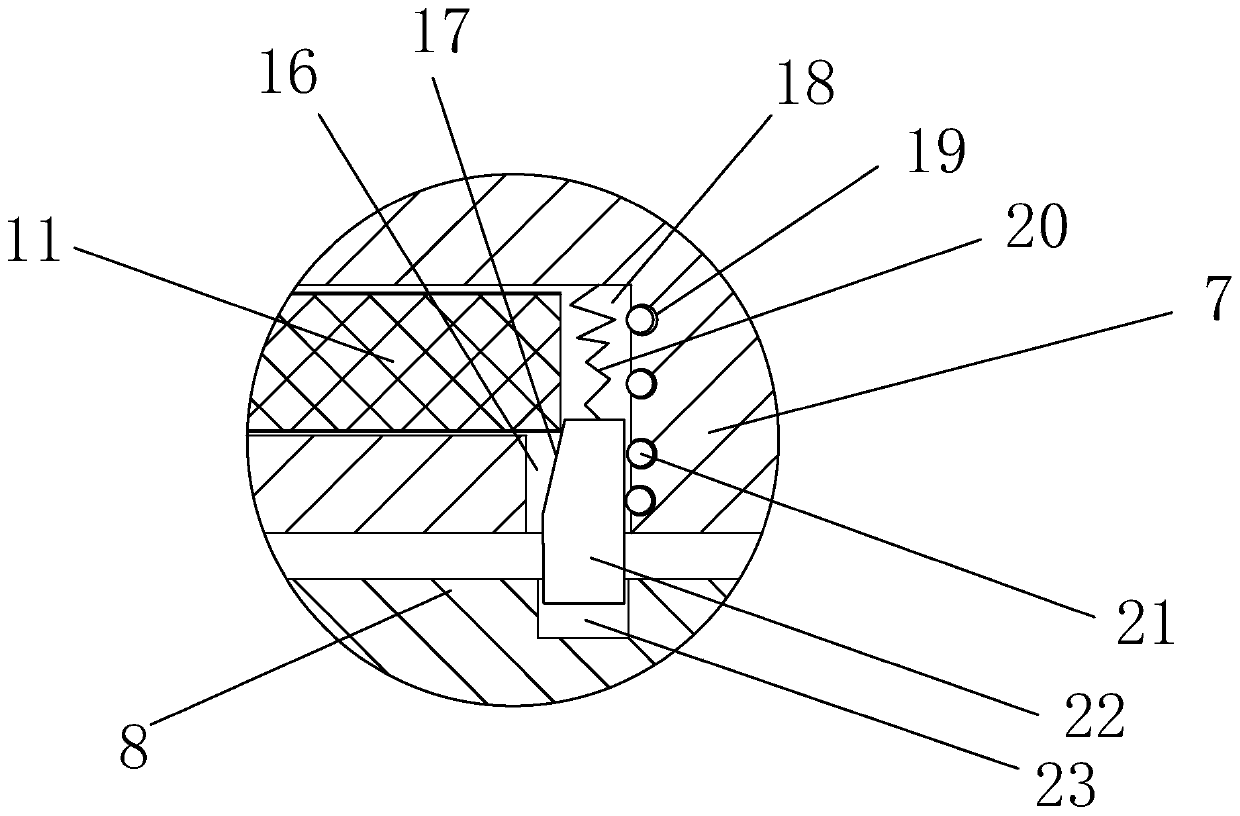

[0022] like figure 1 , 2. As shown in 3, a solar cell light attenuation machine includes a box body 1 and a control box 5, the box body 1 is provided with a rotating motor 4, and the output shaft of the rotating motor 4 is connected with a light source 6 located in the box body 1, The box body 1 is in the shape of a barrel and has a relatively regular shape, which is convenient for placing the light source 6 on the central axis of the box body 1. The rotation motor 4 can drive the light source 6 to rotate in the box body 1. The light source 6 is a xenon lamp, and the light source 6 is uniform. Installed at an angle on the central axis of the box body 1, it is used to simulate sunlight for solar cells. Both the rotating motor 4 and the light source 6 are electrically connected to the control cabinet 5, and the staff can control the rotation speed and speed of the rotating motor 4 by operating the control cabinet 5. For the power of the light source 6, a ring-shaped first brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com