Preparation system and method of polyethylene terephthalate for optical film

A technology of polyethylene terephthalate and a preparation system is applied in the field of preparation system of polyethylene terephthalate for optical films, and can solve the problem of short cleaning and maintenance period of oligomer and small molecules, and oligomerization. It can reduce the thermal degradation reaction, reduce the reaction temperature, and reduce the amount of oligomers precipitated by eliminating the problems such as large amount of precipitation of impurities and small molecular impurities, and dark color of light polyester products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

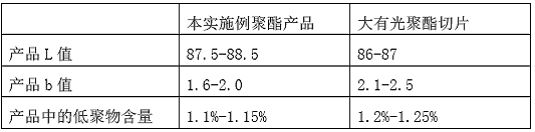

Embodiment 1

[0046] (Example 1, preparation system of polyethylene terephthalate for optical film)

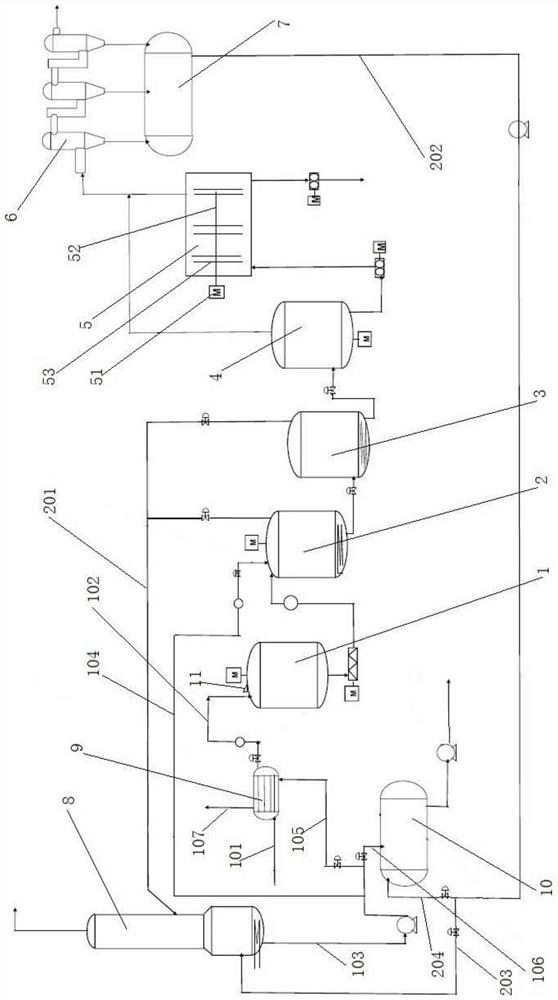

[0047] See figure 1 , The preparation system of polyethylene terephthalate for optical film of the present embodiment comprises slurry tank 1, the first esterification reactor 2, the second esterification reactor 3, the first polycondensation reactor 4, the second Dicondensation reactor 5, condenser 6, condensation EG storage tank 7, rectification tower 8, heat exchanger 9, EG collection tank 10 and connecting pipelines.

[0048] The slurry tank 1 , the first esterification reactor 2 , the second esterification reactor 3 , the first polycondensation reactor 4 , and the second polycondensation reactor 5 are connected sequentially through pipelines. The slurry tank 1 is equipped with a stirring device, and the connecting pipeline between the slurry tank 1 and the first esterification reaction kettle 2 is provided with a density meter, a thermometer and a pump. The first esterification react...

Embodiment 2

[0056] (Example 2, preparation system of polyethylene terephthalate for optical film)

[0057] The preparation system of polyethylene terephthalate for the optical film of the present embodiment is the same as that of Embodiment 1, the difference is that: the feed inlet of the EG supplementary pipeline 104 on the first esterification reactor 2 is not the same as that of the first esterification reactor 2 The discharge line below the rectification column 8 is connected, rather, to the hot EG line 102 .

Embodiment 3

[0058] (Example 3, preparation method of polyethylene terephthalate for optical film)

[0059] The preparation method of the polyethylene terephthalate for the optical film of the present embodiment adopts the preparation system described in Example 1, comprising the following steps:

[0060] ①Preparation system startup: Add ethylene glycol and terephthalic acid in a molar ratio of 1.1 to 1.4:1 to the slurry tank 1 and mix them. Ethylene glycol is output from the EG storage tank, and enters the slurry tank 1 through the normal temperature EG pipeline 101, the heat exchanger 9 and the hot EG pipeline 102. At this time, there is no high-temperature EG in the heat exchanger 9, so it enters the slurry tank 1 is still room temperature EG. Terephthalic acid is added from feed port 11.

[0061] Then the mixture is passed through the first esterification reactor 2 (reacted at 245-255 degrees Celsius, 100-150Kpa for 4-6 hours, and the reaction process is continuously mechanically sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com