A Batch Polishing Method for Small-sized Wooden Special-shaped Parts

A special-shaped and small-sized technology, which is applied in the polishing of wooden special-shaped parts, and in the field of polishing, can solve the problems of low efficiency and achieve high polishing efficiency, good polishing effect, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

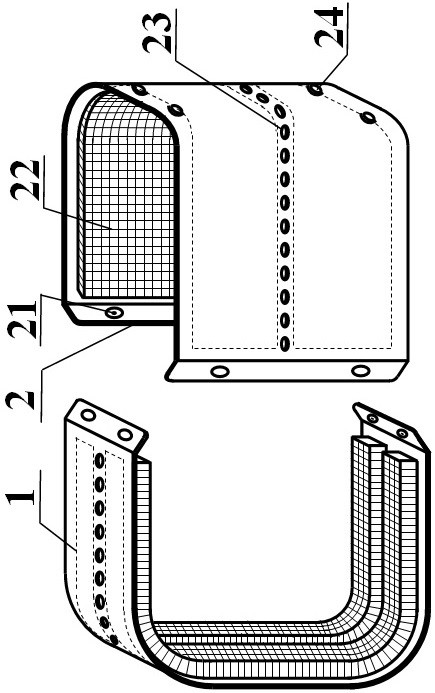

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is a structural schematic diagram of a flexible wrapped brush, which includes a strip brush 1 and a strip brush 2 with the same structure, which can be flexibly bent, wrap, protect and uniformly polish the polished piece. Both the strip brush 1 and the strip brush 2 have a strip-shaped sheet body, a male buckle 21, a brush strip 22, a perforation 23 and a female buckle 24. The sheet-like body is an elongated flexible structure, which can be bent. It is preferably made of non-woven fabric after cutting, and can also be made of other fabrics.

[0034] The male buckle 21 is located at both ends of the inner surface of the sheet body, and the female buckle 24 is located at both sides of the middle of the outer surface of the sheet body. The male buckle 21 and the female buckle 24 are preferably known male and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com