Hydroxylapatite coated collagen-graphene oxide bionic material and preparation method thereof

A hydroxyapatite and collagen technology, which is applied in the field of medicine, can solve the problems of insufficient mechanical strength and easy deformation, and achieves the effects of simple preparation process, low cost and enhanced mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

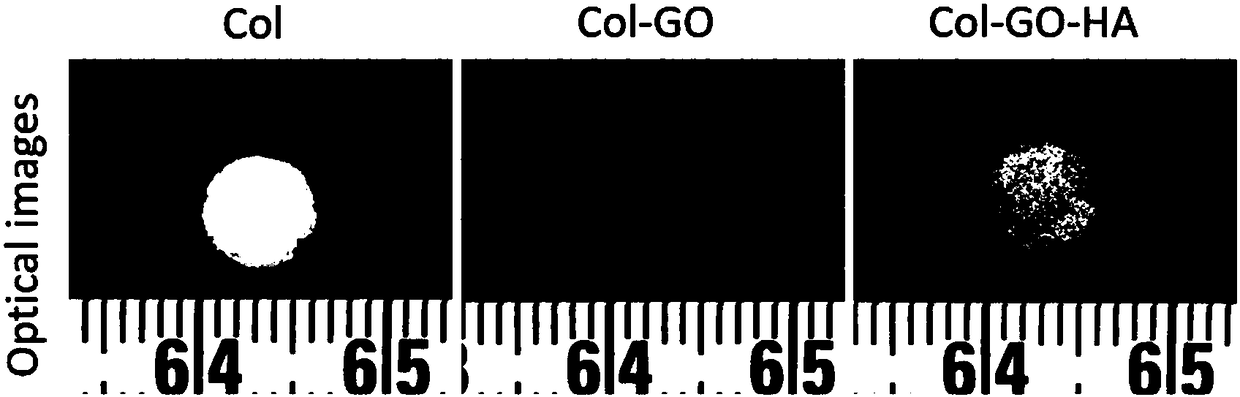

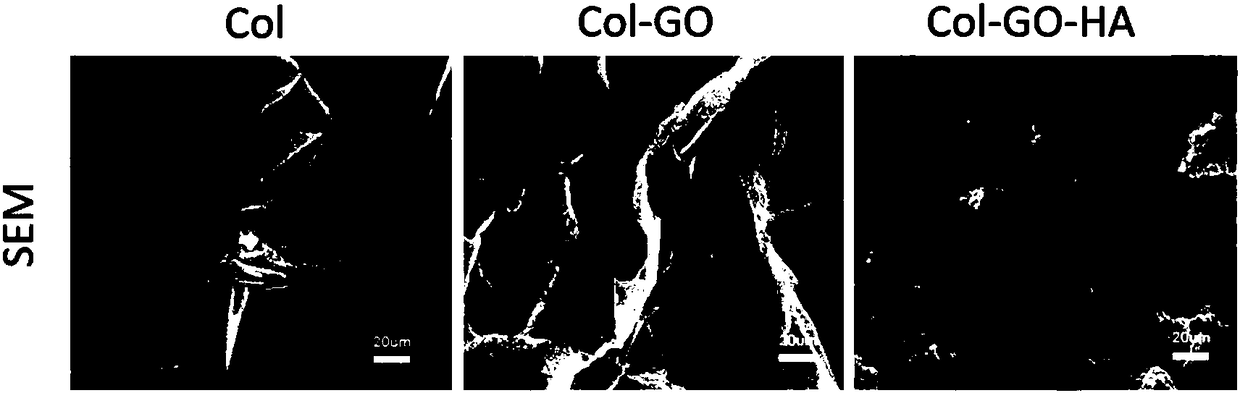

Image

Examples

Embodiment 1

[0064] A composite material with a collagen concentration of 1.5% (W / V) and a graphene oxide concentration of 0.15% (W / V) was prepared, and a hydroxyapatite biomimetic coating was prepared on the surface of the material by using the SBF biomimetic mineralization method. Converted into weight percentages, the weight percentage of type I collagen is 22.5%, the weight percentage of graphene oxide is 3%, and the weight percentage of HA is 74.5%.

[0065] Step 1: Preparation of Collagen-Graphene Oxide Composite Material

[0066] (1) Add 30mg type I collagen to 1ml 0.1M acetic acid (0.285ml glacial acetic acid deionized water to 50ml) solution to obtain a 3% (W / V) collagen solution;

[0067] (2) 3 mg of graphene oxide powder was dissolved in 1 ml of 0.1M acetic acid solution under the assistance of ultrasound to obtain a 0.3% (W / V) graphene oxide solution;

[0068] (3) After mixing equal volumes of 3% (W / V) collagen solution and 0.3% (W / V) graphene oxide solution obtained in step (...

Embodiment 2

[0090] A composite material with a collagen concentration of 1.75% (W / V) and a graphene oxide concentration of 0.175% (W / V) was prepared, and a hydroxyapatite biomimetic coating was prepared on the surface of the material by using the SBF biomimetic mineralization method. Converted into weight percentages, the weight percentage of type I collagen is 26.25%, the weight percentage of graphene oxide is 3.5%, and the weight percentage of HA is 70.25%.

[0091] Step 1: Preparation of Collagen-Graphene Oxide Composite Material

[0092] (1) Add 35mg type I collagen to 1ml 0.1M acetic acid (0.285ml glacial acetic acid deionized water to 50ml) solution to obtain a 3.5% (W / V) collagen solution;

[0093] (2) 3.5mg graphene oxide powder was dissolved in 1ml 0.1M acetic acid solution under the assistance of ultrasound to obtain a 0.35% (W / V) graphene oxide solution;

[0094] (3) After mixing equal volumes of 3.5% (W / V) collagen solution and 0.35% (W / V) graphene oxide solution obtained in ...

Embodiment 3

[0115] A composite material with a collagen concentration of 2% (W / V) and a graphene oxide concentration of 2% (W / V) was prepared, and a hydroxyapatite biomimetic coating was prepared on the surface of the material by using the SBF biomimetic mineralization method. Converted into weight percentage, the weight percentage of type I collagen is 30%, the weight percentage of graphene oxide is 4%, and the weight percentage of HA is 66%.

[0116] Step 1: Preparation of Collagen-Graphene Oxide Composite Material

[0117] (1) Add 40mg type I collagen to 1ml 0.1M acetic acid (0.285ml glacial acetic acid deionized water to 50ml) solution to obtain a 4% (W / V) collagen solution;

[0118] (2) Dissolve 4mg of graphene oxide powder in 1ml of 0.1M acetic acid solution under the assistance of ultrasound to obtain a 0.4% (W / V) graphene oxide solution;

[0119] (3) After mixing equal volumes of 4% (W / V) collagen solution and 0.4% (W / V) graphene oxide solution in step (1) and step (2) of this pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com