Heated surface anti-abrasion membrane type water-cooled wall and preparation method thereof

A membrane-type water-cooling wall and heating surface technology, which can be used in combustion methods, lighting and heating equipment, combustion equipment, etc., can solve problems such as low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] As mentioned above, in the existing methods of anti-corrosion of boiler water wall tubes, the use of anti-wear tiles is also called anti-wear cover, anti-wear plate, anti-wear protection tile, anti-wear cover plate, anti-corrosion cover plate, boiler climbing tube, Compared with other anti-abrasion laser cladding, surfacing welding anti-corrosion and thermal spraying anti-wear and anti-corrosion coating methods, methods such as anti-wear pressure plate are low in cost, easy to operate, and have better anti-wear effects, but the heat transfer efficiency lower. In view of this, the inventors of the present invention have conducted a lot of research on the anti-corrosion technology of boiler water-cooled wall tubes by using anti-wear tiles.

[0062] The inventors have found through research that since the inner diameter of the anti-wear tile is usually 1-5 mm larger than the outer diameter of the water-cooled wall tube, the gap between the anti-wear tile and the tube wall ...

Embodiment 1

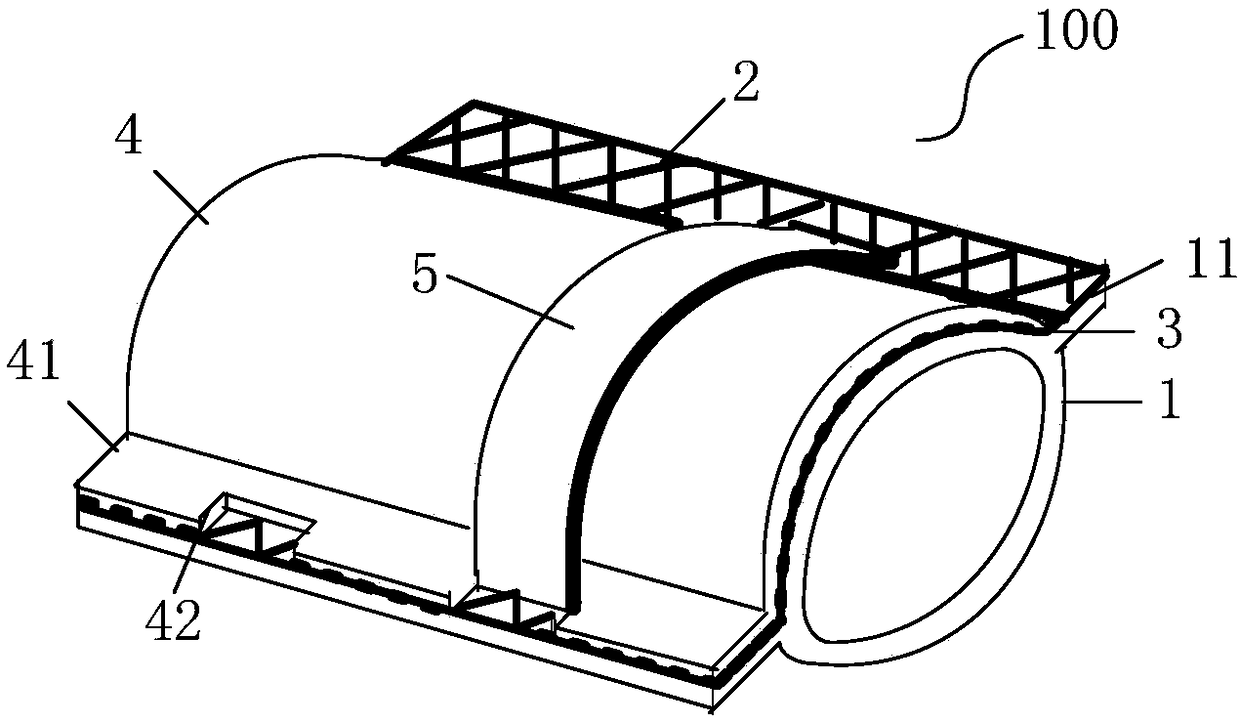

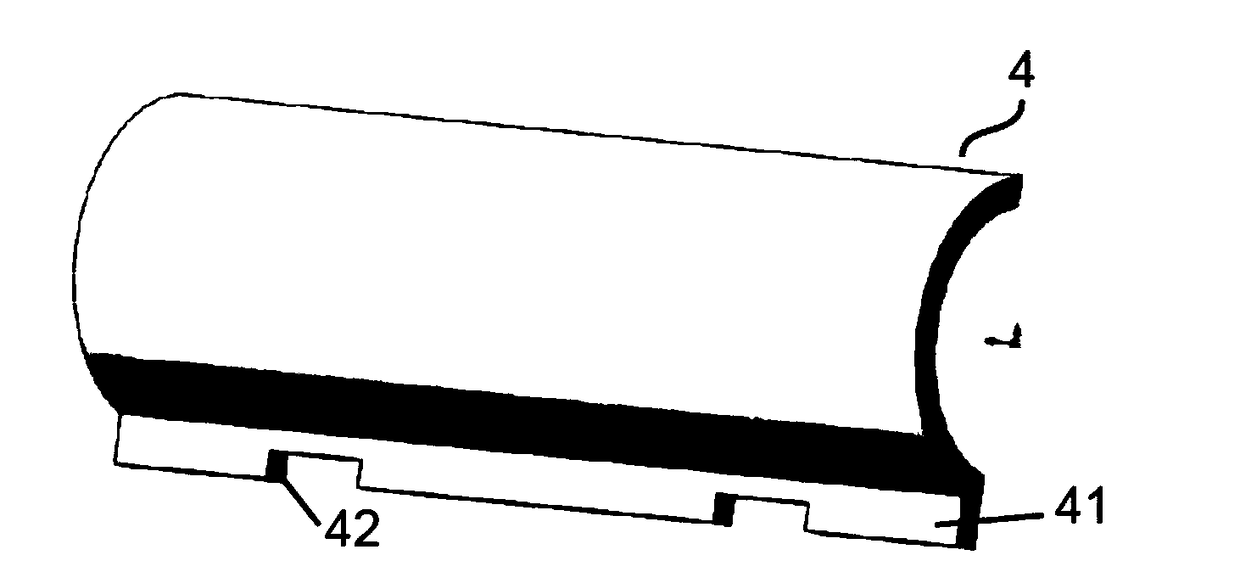

[0113] The anti-wear tile is joined to the finned tube heating surface of the membrane water cooling wall to manufacture a membrane water cooling wall with anti-abrasion heating surface.

[0114] (1) The heating surface of the finned tube 1 on the membrane water cooling wall is subjected to sandblasting and roughening treatment, so that the surface roughness of the finned tube's heating surface is 40 microns (PCWI 0918 anchor pattern instrument, Australian PCWI company);

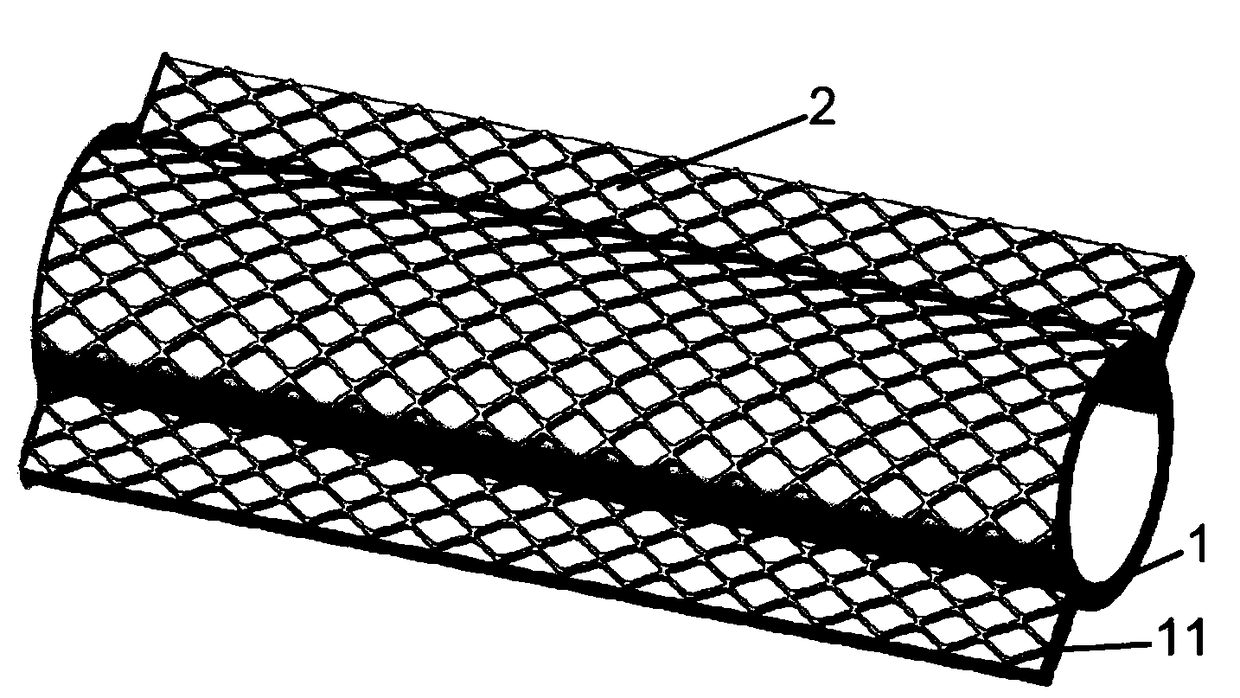

[0115] (2) By welding on the fins 11 of the finned tube 1, the expanded metal mesh 2 (the material is 1Gr25Ni20Si2 or Ni60A, the thickness is 1mm) having the same size and shape as the heating surface of the finned tube 1 is welded to the finned tube 1. The heating surface of sheet tube 1, such as figure 2 shown;

[0116] (3) Mix KN1000 anti-resistant brand high-temperature and wear-resistant adhesive or silicon carbide particles with 1280°C high-temperature-resistant sealant at a ratio of 3:1 and use it a...

Embodiment 2

[0128] The anti-wear tile is joined to the finned tube heating surface of the membrane water cooling wall to manufacture a membrane water cooling wall with anti-abrasion heating surface.

[0129] (1) The heating surface of the finned tube 1 on the membrane water cooling wall is subjected to sandblasting and roughening treatment, so that the surface roughness of the finned tube's heating surface is 75 microns (PCWI 0918 anchor pattern instrument, Australian PCWI company);

[0130] (2) By welding on the fins 11 of the finned tube 1, the expanded metal mesh 2 (the material is 1Gr25Ni20Si2 or Ni60A, the thickness is 5mm) having the same size and shape as the heating surface of the finned tube 1 is welded to the finned tube 1. The heating surface of sheet tube 1, such as figure 2 shown;

[0131] (3) Press the high-temperature-resistant composite adhesive reinforced by silicon carbide particles into the grid of the expanded metal 2 welded on the heating surface of the fin tube 1 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com