Magnesium alloy micro-arc oxidation black ceramic membrane and preparation method thereof

A technology of micro-arc oxidation and black ceramics, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of increasing operation links, easy to fall off, poor bonding performance, etc., and achieve good corrosion resistance of the film layer, Reduced arcing voltage and strong film-base binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

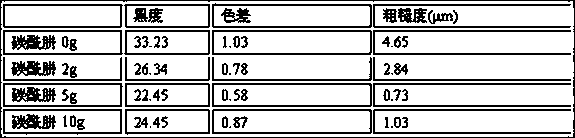

Embodiment 1

[0026] A method for preparing a magnesium alloy micro-arc oxidation black ceramic film, comprising the following steps:

[0027] (1) Pretreatment: Cut a sample with a size of 20mm×20mm×1mm from a magnesium alloy sheet of model AZ91D, and use 150#, 400#, 600#, 800#, 1200#, 2000# SiC sandpaper to The surface of the magnesium-aluminum alloy is polished until the direction of the scratch is consistent, and then it is cleaned with acetone, absolute ethanol, and deionized water in an ultrasonic wave for 10 minutes to remove oil stains, and then dried for later use.

[0028] (2) Configure the electrolyte: weigh 2g of carbohydrazide, sodium silicate Na 2 SiO 3 20g, sodium hexametaphosphate 25g, potassium fluoride KF 12g, ammonium metavanadate NH 4 VO 3 12g, sodium hydroxide NaOH 2g, ethylenediaminetetraacetic acid EDTA 4g, sodium citrate 2g, dissolve in 1L deionized water, put in a stainless steel tank, stir with a magnetic stirrer to fully dissolve.

[0029] (3) Magnesium alloy...

Embodiment 2

[0034] (1) Pretreatment: Cut a sample with a size of 20mm×20mm×1mm from a magnesium alloy sheet of model AZ91D, and use 150#, 400#, 600#, 800#, 1200#, 2000# SiC sandpaper to The surface of the magnesium-aluminum alloy is polished until the direction of the scratch is consistent, and then it is cleaned with acetone, absolute ethanol, and deionized water in an ultrasonic wave for 10 minutes to remove oil stains, and then dried for later use.

[0035] (2) Prepare the electrolyte: weigh carbohydrazide 5g, sodium silicate 15g, sodium hexametaphosphate 20g, potassium fluoride 10g, ammonium metavanadate 8g, sodium hydroxide 4g, EDTA 1g, sodium citrate at room temperature 2g, dissolved in 1L deionized water, placed in a stainless steel tank, stirred with a magnetic stirrer to fully dissolve.

[0036] (3) Magnesium alloy micro-arc oxidation coloring

[0037] The magnesium alloy sample after the above pretreatment is used as the anode, and is completely immersed in the above-mentioned ...

Embodiment 3

[0041] (1) Pretreatment: Cut a sample with a size of 20mm×20mm×1mm from a magnesium alloy sheet of model AZ91D, and use 150#, 400#, 600#, 800#, 1200#, 2000# SiC sandpaper to The surface of the magnesium-aluminum alloy is polished until the direction of the scratch is consistent, and then it is cleaned with acetone, absolute ethanol, and deionized water in an ultrasonic wave for 10 minutes to remove oil stains, and then dried for later use.

[0042] (2) Prepare the electrolyte: weigh 10g of carbohydrazide, 25g of sodium silicate, 30g of sodium hexametaphosphate, 20g of potassium fluoride, 15g of ammonium metavanadate, 5g of sodium hydroxide, and EDTA at room temperature. 5g of sodium citrate, 3g of sodium citrate, dissolved in 1L of deionized water, placed in a stainless steel tank, stirred with a magnetic stirrer to fully dissolve.

[0043] (3) Magnesium alloy micro-arc oxidation coloring

[0044] The magnesium alloy sample after the above pretreatment is used as the anode, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com