Preparation method of thiolated chitosan nano modified attapulgite soil passivator

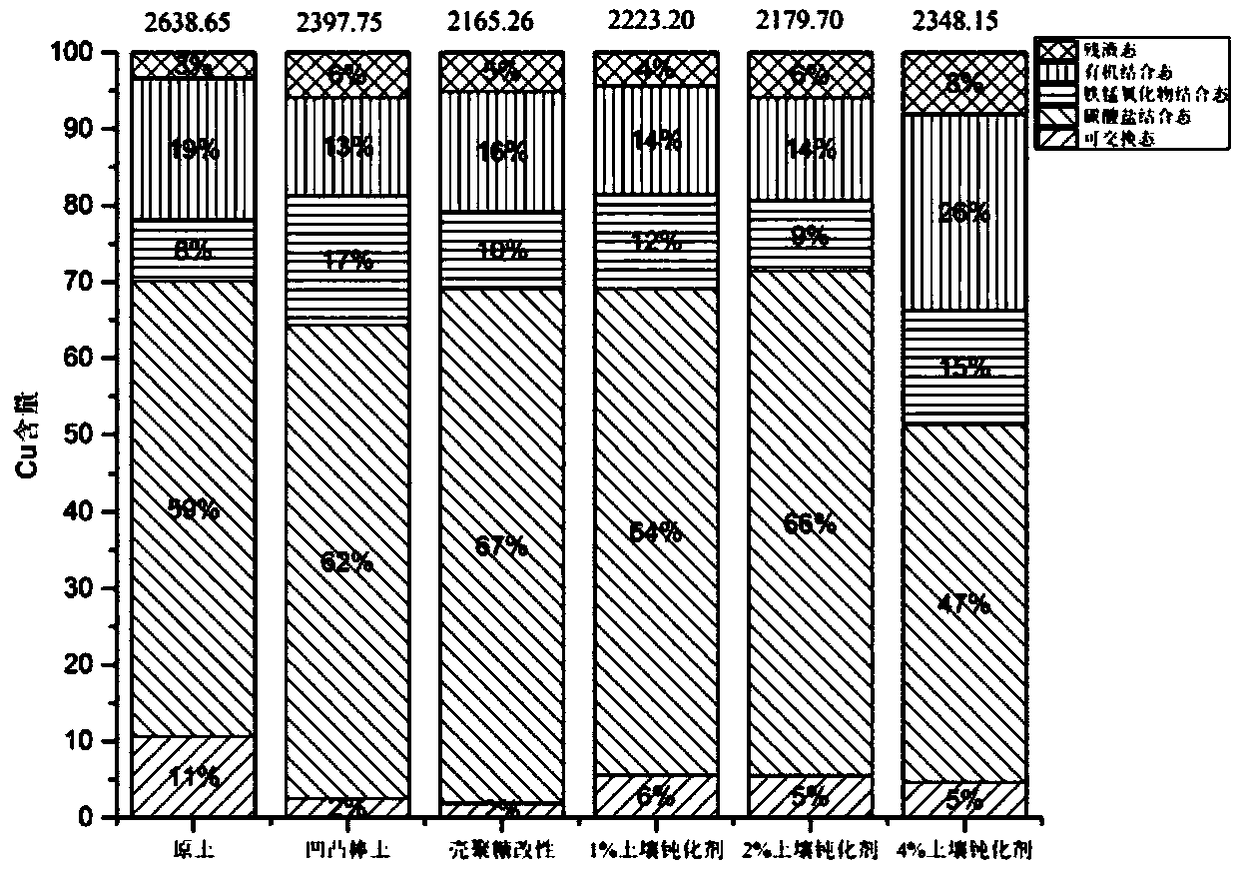

A thiolated chitosan and chitosan modification technology, applied in chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve the problems of passivation group load, lack of adsorption effect, etc. The effect of increasing the residual content, improving the passivation effect, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

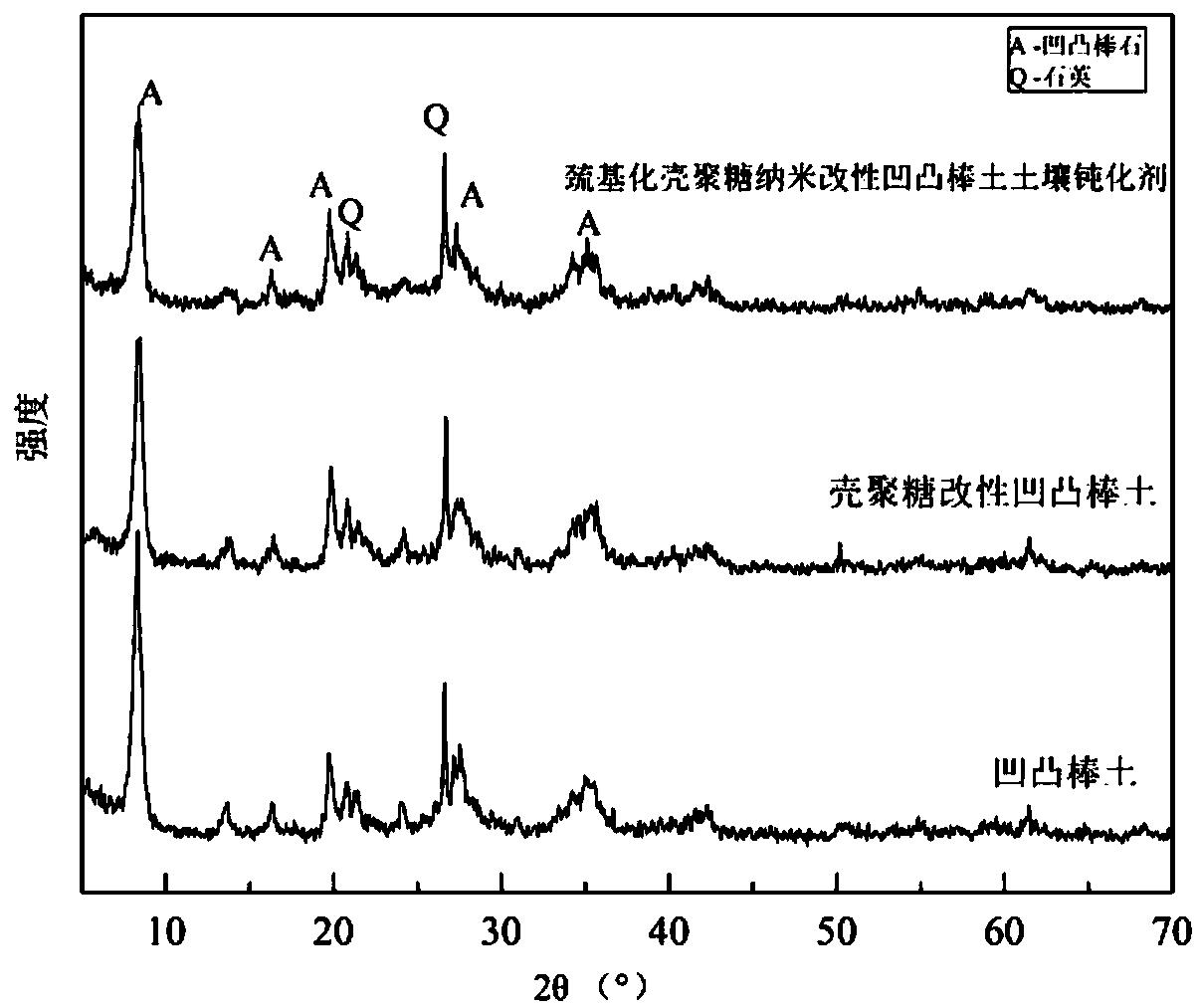

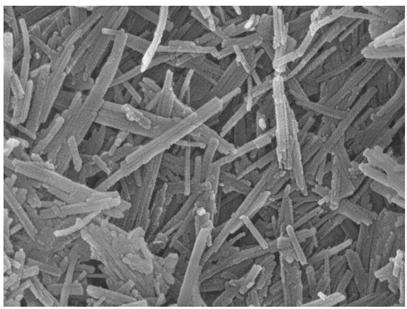

[0034] (1) Uniformly mix 30 g of attapulgite, 3 g of chitosan, 0.1 g of sodium alkylaryl sulfonate, and 400 mL of deionized water, and disperse ultrasonically for 15 minutes to obtain a suspension;

[0035] Pour the suspension into a polytetrafluoroethylene reactor, react in a high-temperature furnace at 180°C for 24 hours, cool to room temperature, and centrifuge the product, wash it with 10% ethanol and deionized water three times, and then filter it with suction. Dry in an oven at 80°C for 1 hour, grind through a 200-mesh sieve, and the solid part is chitosan-modified attapulgite.

[0036] (2) Evenly mix 20 g of chitosan-modified attapulgite with 150 mL of thioglycolic acid, add 2 mL of concentrated sulfuric acid as a catalyst, shake in a water bath at 40 ° C for 24 h, centrifuge, wash with deionized water until the filtrate is neutral, and then Wash with a small amount of ethanol, dry at 40°C for 3 hours, and grind through a 200-mesh sieve to obtain a mercapto-chitosan nan...

Embodiment 2

[0043] (1) Uniformly mix 40 g of attapulgite, 5 g of chitosan, 0.12 g of sodium alkylaryl sulfonate, and 500 mL of deionized water, and ultrasonically disperse for 15 minutes to obtain a suspension;

[0044] Pour the suspension into a polytetrafluoroethylene reactor, react in a high-temperature furnace at 200°C for 20 hours, cool to room temperature, and centrifuge the product, wash it with 10% ethanol and deionized water three times, and then filter it with suction. Dry in an oven at 100°C for 80 minutes, grind through a 200-mesh sieve, and the solid part is chitosan-modified attapulgite.

[0045] (2) Evenly mix 10 g of chitosan-modified attapulgite with 50 mL of thioglycolic acid, add 1 mL of concentrated sulfuric acid as a catalyst, shake in a water bath at 50 ° C for 20 h, centrifuge, wash with deionized water until the filtrate is neutral, and then Wash with a small amount of ethanol, dry at 40°C for 2 hours, and grind through a 200-mesh sieve to obtain a thiolated chitos...

Embodiment 3

[0049] (1) Uniformly mix 30 g of attapulgite, 4 g of chitosan, 0.1 g of fatty alcohol polyoxyethylene ether, and 500 mL of deionized water, and ultrasonically disperse for 15 minutes to obtain a suspension;

[0050] Pour the suspension into a polytetrafluoroethylene reactor, react in a high-temperature furnace at 200°C for 20 hours, cool to room temperature, and centrifuge the product, wash it with 10% ethanol and deionized water three times, and then filter it with suction. Dry in an oven at 100°C for 80 minutes, grind through a 200-mesh sieve, and the solid part is chitosan-modified attapulgite.

[0051] (2) Evenly mix 10 g of chitosan-modified attapulgite with 50 mL of thioglycolic acid, add 1 mL of concentrated sulfuric acid as a catalyst, shake in a water bath at 50 ° C for 20 h, centrifuge, wash with deionized water until the filtrate is neutral, and then Wash with a small amount of ethanol, dry at 40°C for 2 hours, and grind through a 200-mesh sieve to obtain a thiolate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com