Reduction and modification method of graphite oxide and application of graphite oxide in modified epoxy resin

A technology of epoxy resin and modification method, which is applied in the field of preparation of nanocomposite materials, can solve the problem of inability to realize long-term stable storage of graphene/epoxy resin, weak interfacial bonding force between graphene and epoxy resin composite materials, and unfavorable graphene Composite with epoxy resin and other issues to achieve the effect of convenient and fast transportation and storage, uniform and controllable content, and effective dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

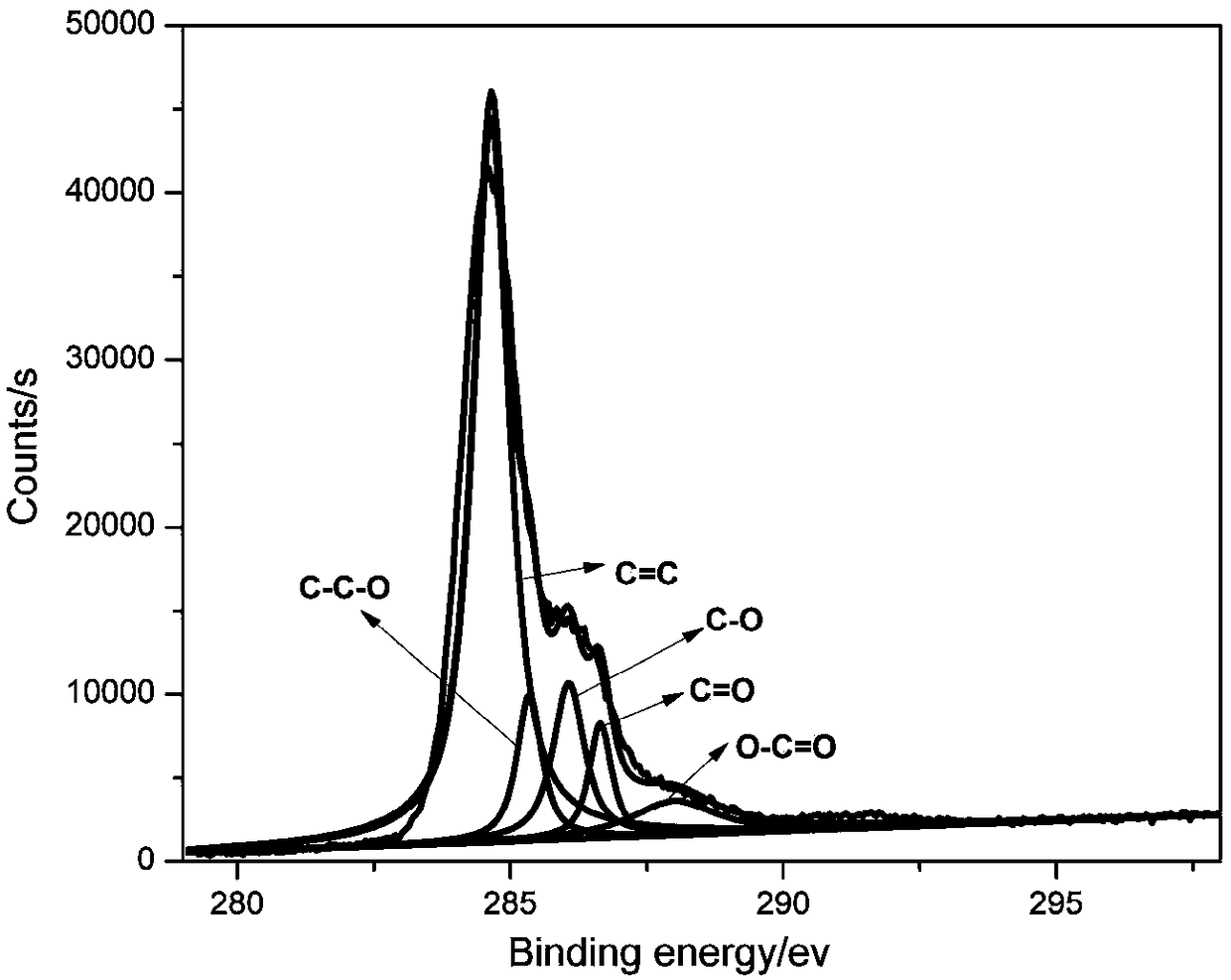

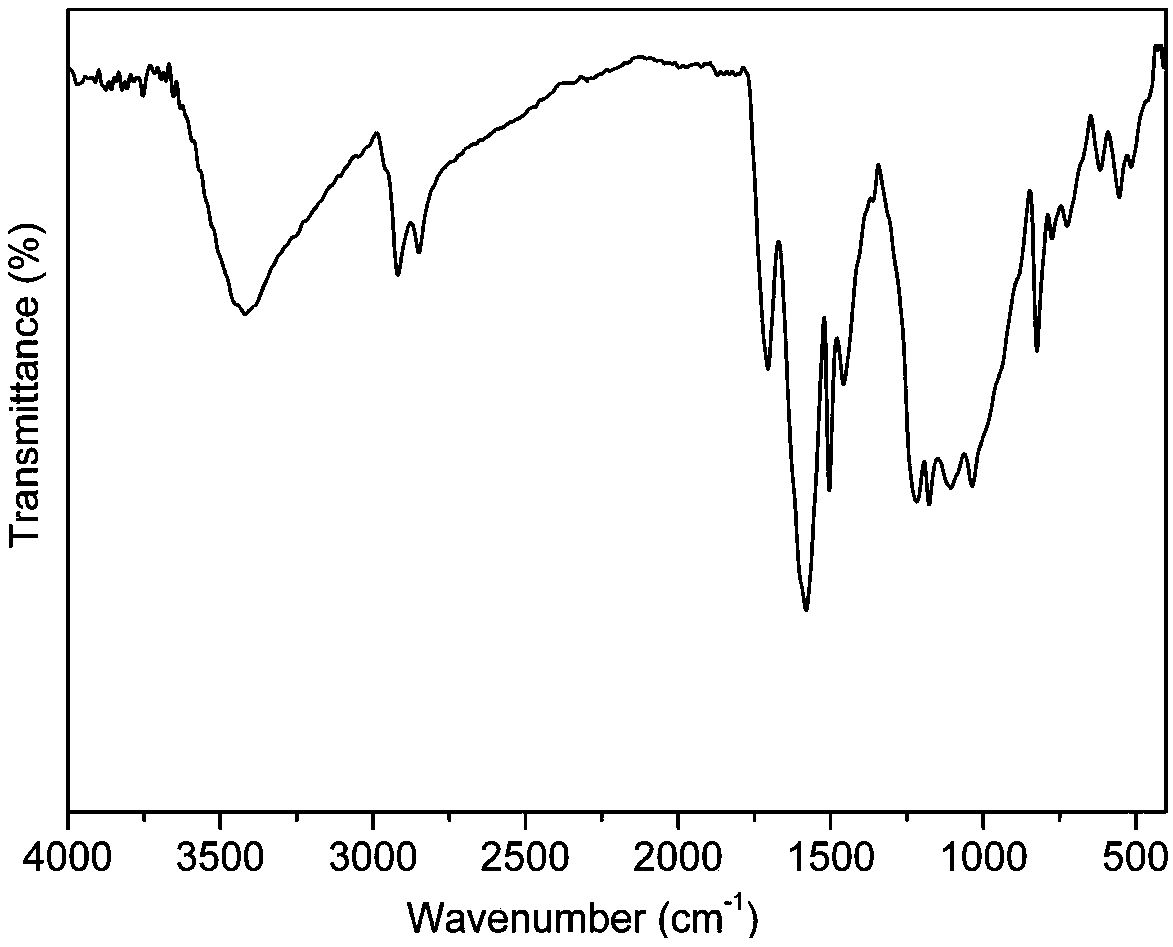

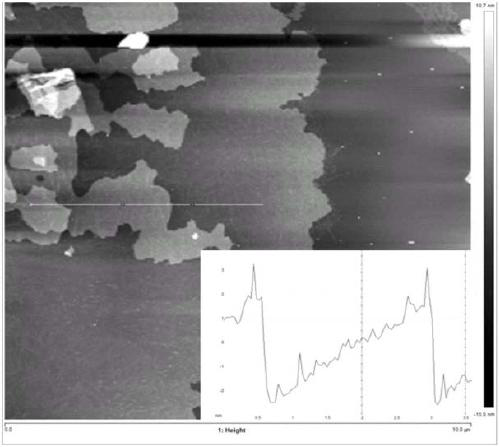

Method used

Image

Examples

Embodiment 1

[0025] Dissolve the acetylation reagent composed of 6.12 g of acetic anhydride and 14.2 g of pyridine, and 18.8 g of urushiol in 30 mL of xylene, heat up to 80-100 ° C for 4 hours, cool to room temperature, add 0.1 mol / L NaOH aqueous solution to wash, To pH = 7, liquid separation, removal of the water layer, to obtain the product acetylated urushiol. Dissolve 17.8g of acetylated urushiol, 23g of E44 epoxy resin and 0.2g of N,N-dimethylbenzylamine in 30mL of xylene, heat up to 50°C, stir, react for 6h, add 1mol / L NaOH ethanol solution, react at 50°C for 3h, and cool to room temperature to obtain the crude product. Wash with aqueous solution until pH = 7, remove the water layer, take the organic phase and rotary evaporate, remove excess epoxy resin, and obtain the product urushiol epoxy resin. The obtained urushiol epoxy resin and the graphene oxide prepared by the Hummer method were respectively dissolved and dispersed in N,N-dimethylformamide (DMF) solvent to prepare urushio...

Embodiment 2

[0030]Dissolve the acetylation reagent composed of 6.12 g of acetic anhydride and 14.2 g of pyridine, and 18.8 g of urushiol in 30 mL of toluene, heat up to 80-100 ° C for 4 h, cool to room temperature, add 0.1 mol / L NaOH aqueous solution to wash, until pH=7, liquid separation, removal of the water layer to obtain the product acetylated urushiol. Dissolve the obtained 17.8g of acetylated urushiol, 23g of ethylene glycol diglycidyl ether and 0.2g of benzyltriethylammonium chloride in 30mL of toluene, raise the temperature to 50°C, stir, react for 6h, and add 1M NaOH ethanol solution , 50 ° C reaction for 3h, cooled to room temperature to obtain a crude product. Wash with aqueous solution until pH = 7, remove the water layer, take the organic phase and rotary evaporate, remove excess epoxy resin, and obtain the product urushiol epoxy resin. The obtained urushiol epoxy resin and the graphene oxide prepared by the Hummer method were respectively dissolved and dispersed in N,N-dim...

Embodiment 3

[0032] Dissolve the acetylation reagent composed of 6.12 g of acetic anhydride and 14.2 g of pyridine, and 18.8 g of urushiol in 30 mL of toluene, heat up to 80-100 ° C for 4 h, cool to room temperature, add 0.1 mol / L NaOH aqueous solution to wash, until pH=7, liquid separation, removal of the water layer to obtain the product acetylated urushiol. Dissolve 17.8g of acetylated urushiol, 23g of E51 epoxy resin and 0.2g of benzyltriethylammonium chloride in 30mL of toluene, heat up to 50°C, stir, react for 6h, add 1M NaOH ethanol solution , 50 ° C reaction for 3h, cooled to room temperature to obtain a crude product. Wash with aqueous solution until pH = 7, remove the water layer, take the organic phase and rotary evaporate, remove excess epoxy resin, and obtain the product urushiol epoxy resin. The obtained urushiol epoxy resin and the graphene oxide prepared by the Hummer method were respectively dissolved and dispersed in N,N-dimethylformamide (DMF) solvent to prepare urushio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com