Method for preparing polyolefin with ultra-high molecular weight

An ultra-high molecular weight, polyolefin technology, applied in the field of olefin polymerization, can solve the problems of unregulated chain entanglement, and achieve the effect of inhibiting the formation of chain entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

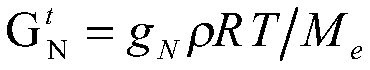

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing ultra-high molecular weight polyolefin, the steps are:

[0028] The reactor was purged with high-purity nitrogen to remove air and water in the reactor. Adjust the temperature of the reactor (slurry polymerization reactor) to 60°C, add 400ml of n-heptane, blow in nitrogen gas for 2bar, and add 2μmol of catalyst in sequence (select aryloxyimine ligand titanium-based single-site catalyst, that is, FI catalyst , of course, FI catalysts with other structures can also be used), 2000μmol cocatalyst (choose trimethylaluminoxane), 3bar olefin monomer (choose ethylene); before the reaction, the nitrogen in the solvent is assisted by ultrasonic waves into a diameter of 100nm~ 1000μm nano-microbubbles, and then start the polymerization reaction, the reaction pressure is 3bar, the reaction time is 2h, and the ultrasonic wave is assisted until the end of the polymerization reaction, wherein the ultrasonic frequency is 20KHz, and the ultrasonic power is 1kW. F...

Embodiment 2

[0031] A method for preparing ultra-high molecular weight polyolefin, the steps are:

[0032] The reactor was purged with high-purity nitrogen to remove air and water in the reactor. Adjust the temperature of the reactor (slurry polymerization reactor) to 60°C, add 400ml of n-heptane, blow in nitrogen gas for 2bar, and add 2μmol of catalyst in sequence (select aryloxyimine ligand titanium-based single-site catalyst, that is, FI catalyst ), 2000 μmol cocatalyst (select trimethylaluminoxane), 3bar olefin monomer (select ethylene); before the reaction, the nitrogen in the solvent is changed into nano-micro-bubbles with a diameter of 150nm by a nano-micro-bubble generator, and then the polymerization starts For the reaction, the reaction pressure is 60 bar, the reaction time is 2 hours, and the nano-microbubble generator is assisted until the polymerization reaction is completed. Finally, polyethylene pellets are obtained.

[0033] The weight-average molecular weight of the prep...

Embodiment 3

[0035] A method for preparing ultra-high molecular weight polyolefin, the steps are:

[0036]The reactor was purged with high-purity nitrogen to remove air and water in the reactor. Adjust the temperature of the reactor (slurry polymerization reactor) to 60°C, add 400ml of n-heptane, blow nitrogen gas at 2 bar, and add 2 μmol of catalyst (select aryloxyimine ligand titanium-based single active site supported by silica) in sequence Catalyst, that is, FI catalyst), 200μmol cocatalyst (trimethylaluminoxane is selected), 3bar olefin monomer (ethylene is selected); before the reaction, the nitrogen in the solvent is changed into a nano-micro bubble generator with a diameter of 150nm bubbles, and then start the polymerization reaction, the reaction pressure is 15bar, the reaction time is 2h, and the nano-microbubble generator is assisted until the polymerization reaction ends. Finally, polyethylene pellets are obtained.

[0037] The weight-average molecular weight of the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com