A kind of high-yield preparation method of high-purity dimethyl diallyl ammonium chloride monomer

A dimethyl diallyl ammonium chloride high-yield technology, applied in the field of high-purity dimethyl diallyl ammonium chloride monomer high-yield preparation, can solve the problem of low reaction yield and process Complicated, many process steps, etc., to achieve the effect of low content, less impurities and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

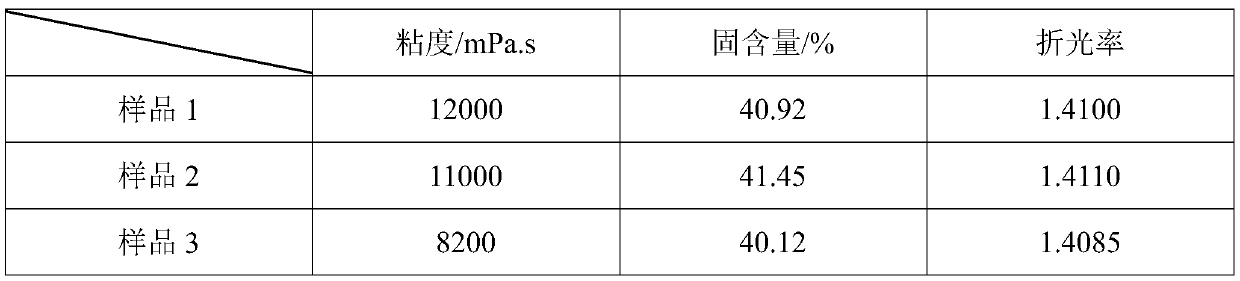

Embodiment 1

[0061] A kind of preparation method of high-purity DMDAAC monomer high yield, its step is:

[0062] Tertiary amination reaction stage: pump 141kg of 40% dimethylamine aqueous solution into a sealed and pressure-resistant reactor equipped with speed-adjustable agitator, pressure gauge, online pH meter, cooling water pipe, heating water pipe, feeding pump, and vacuum pump , circulating water to maintain the temperature in the reactor at 25°C. The reaction kettle was sealed, and the pressure in the kettle was observed with a pressure gauge, and the reaction in the tertiary amination stage was started, and the temperature was controlled at 30°C. Described feeding pump, wherein chloropropene uses a pump, dimethylamine aqueous solution and sodium hydroxide aqueous solution can use a pump

[0063] Step (1): Add 60kg of allyl chloride dropwise into the reactor, and finish adding one-third of the amount of allyl chloride dropwise within 10min-20min, control the pressure in the kettle ...

Embodiment 2

[0073] A kind of preparation method of high-purity DMDAAC monomer high yield, its step is:

[0074]Tertiary amination reaction stage: pump 141kg of 40% dimethylamine aqueous solution into a sealed and pressure-resistant reactor equipped with speed-adjustable agitator, pressure gauge, online pH meter, cooling water pipe, heating water pipe, feeding pump, and vacuum pump , circulating water to maintain the temperature in the reactor at 25°C. The reaction kettle was sealed, and the pressure in the kettle was observed with a pressure gauge, and the reaction in the tertiary amination stage was started, and the temperature was controlled at 40°C. Described feeding pump, wherein chloropropene uses a pump, dimethylamine aqueous solution and sodium hydroxide aqueous solution can use a pump

[0075] Step (1): Add 65kg of allyl chloride dropwise into the reaction kettle, and finish adding one-third of the amount of allyl chloride dropwise in 10min-20min. Under reaction 1h.

[0076] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com