Brazing filler metal for brazing titanium alloy and steel or titanium aluminum alloy as well as steel

A technology of titanium aluminum alloy and titanium alloy, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., to achieve good wetting effect and avoid mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

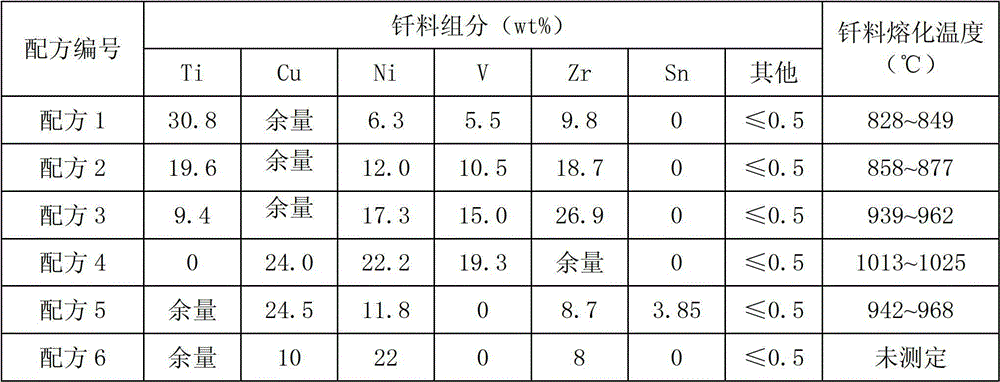

[0032] Adopt 99.99wt% high-purity Ti, Cu, Ni, Zr and V thin plate as raw material, weigh a certain amount of raw material according to the solder composition ratio of formula 1 in Table 1, smelt more than 5 times in vacuum electric arc furnace, make The components are mixed evenly, and the component loss of the last smelting is less than 0.1wt%. The smelted alloy ingot was spun into a thin strip with a thickness of about 50 μm by using a copper roll rapid cooling method (the surface speed of the copper roll was 40 m / s), and the solder 1 was obtained. Use the above brazing material 1 to braze titanium-aluminum alloy (Ti-48Al-2Cr-2Nb, at%) and 40Cr steel (Fe-0.4C-1.0Cr-0.7Mn-0.3Si-0.2Ni, wt%). The welding temperature is 900°C, the holding time is 10 minutes, the heating rate is 30°C / min, and the temperature is kept at 800°C for 5 minutes during the heating process to make the temperature in the brazing furnace uniform.

[0033] After the brazing is completed, the brazing seam i...

Embodiment 2

[0036] Solder 2 was prepared in the same manner as in Example 1, except that the solder components of formula 2 in Table 1 were used. In addition, except that the brazing temperature is 930 ° C, the same process parameters as in Example 1 are used to conduct titanium alloy (Ti-48Al-2Cr-2Nb, at%) and 40Cr steel (Fe-0.4C-1.0Cr-0.7Mn -0.3Si-0.2Ni, wt%) for brazing, after the brazing is completed, observe the joint morphology and implement the tensile test in the same way as in Example 1. The results show that: (1) The solder has good spreadability on the surface of 40Cr steel and titanium-aluminum alloy base metal. The width of the solder before brazing is about 2mm, and the average width after spreading is about 5mm. It is about 2.5 times of the width before welding; (2) An obvious reaction zone (about 8 μm in width) is formed between the brazing material and the titanium-aluminum alloy base material, and an interdiffusion layer is also formed between the brazing material and th...

Embodiment 3

[0038] Solder 3 was prepared in the same manner as in Example 1, except that the solder components of formula 3 in Table 1 were used. Except that the brazing temperature was 1000°C, the same process parameters as in Example 1 were used to TC4 titanium alloy (Ti90-Al6-V4, wt%) and 40Cr steel (Fe-0.4C-1.0Cr-0.7Mn-0.3Si- 0.2Ni, wt%) for brazing, after brazing, the same method as in Example 1 was used to observe the joint morphology and perform a tensile test. The results show that: (1) The solder has good spreadability on the surface of TC4 titanium alloy and 40Cr steel base metal. The width of the solder before brazing is about 2mm, and the average width after spreading is about 5mm. It is about 2.5 times the width before welding; (2) A 10μm reaction zone is formed between the brazing material and the TC4 titanium alloy base material, and an interdiffusion layer is also formed between the brazing material and the 40Cr steel base material, and the thickness of the interdiffusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com