A kind of soluble bio-organic fertilizer and its production method

A bio-organic fertilizer, soluble technology, applied in the direction of organic fertilizer, fertilizer made of biological waste, fertilizer mixture, etc., can solve the problems of high transportation cost of liquid fertilizer, low content of other nutrients, and no beneficial live bacteria, etc., to improve The effect of soil rhizosphere environment, promoting crop growth, and easy adjustment of nutrient distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

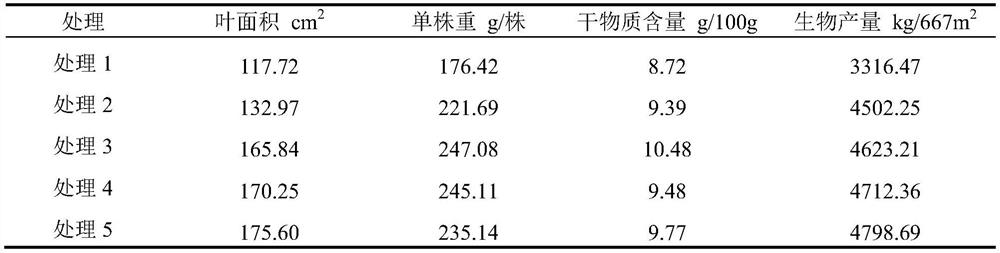

Examples

Embodiment 1

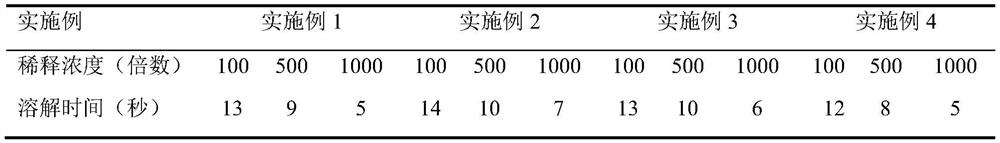

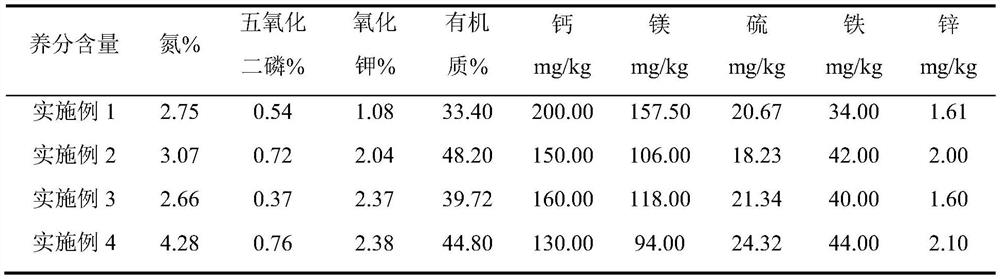

[0055] Embodiment 1: the preparation of soluble biological organic fertilizer

[0056] 1. Raw material composition:

[0057] 20 parts of corn gluten, 10 parts of soybean protein, 5 parts of potassium fulvic acid, 10 parts of Bacillus, 5 parts of nitrogen-fixing bacteria (CICC 20603), 5 parts of Trichoderma harzianum, 10 parts of soluble absorption carrier, 0.3 parts of additives, 40 parts of water share;

[0058] Wherein, said bacillus comprises 5 parts of subtilis (CICC 10732), 5 parts of amyloliquefaciens bacillus (CICC 10036); said soluble absorption carrier comprises 5 parts of glucose and 5 parts of fructose; said additive comprises 0.1 part of amino acid 0.2 serving of vitamin C.

[0059] 2. Preparation method:

[0060] The corn gluten, soybean protein, and potassium fulvic acid are firstly mixed and ground, fully mixed with water, inoculated with cultured Bacillus, nitrogen-fixing bacteria, and Trichoderma harzianum, and then additives are added to form a liquid prod...

Embodiment 2

[0061] Embodiment 2: the preparation of soluble biological organic fertilizer

[0062] 1. Raw material composition:

[0063] 10 parts of potassium fulvic acid, 5 parts of fermented molasses, 20 parts of soybean protein, 10 parts of Bacillus, 10 parts of Trichoderma, 15 parts of soluble absorption carrier, 0.4 parts of additives, 30 parts of water;

[0064] Described bacillus comprises 5 parts of Bacillus amyloliquefaciens (CICC 10036) and 5 parts of Bacillus licheniformis; Described Trichoderma comprises 5 parts of Trichoderma viridans (CICC 13029) and 5 parts of Trichoderma harzianum (CICC 41290); The soluble The absorption carrier includes 10 parts of glucose and 5 parts of sucrose; the additive includes 0.2 part of amino acid and 0.2 part of carotenoid.

[0065] 2. Preparation method:

[0066] Potassium fulvic acid and soybean protein are mixed and ground, fully mixed with fermented molasses and water, inoculated with cultured bacillus and trichoderma, and added with addi...

Embodiment 3

[0067] Embodiment 3: the preparation of soluble biological organic fertilizer

[0068] 1. Raw material composition:

[0069] 20 parts of corn gluten, 10 parts of soybean protein, 10 parts of potassium fulvic acid, 5 parts of Bacillus, 5 parts of Trichoderma, 5 parts of nitrogen-fixing bacteria, 15 parts of soluble absorption carrier, 0.5 parts of additives, 40 parts of water;

[0070] The bacillus is Bacillus subtilis (CICC 10732), and the Trichoderma is Trichoderma viride (CICC13029); the soluble absorption carrier includes 10 parts of glucose, 5 parts of sucrose; the additive includes 0.2 part of vitamin C, 0.2 part of amino acid and 0.1 parts carotenoids.

[0071] 2. Preparation method:

[0072] Firstly, corn gluten, soybean protein, and potassium fulvic acid are mixed and ground, fully mixed with water, inoculated with cultured Bacillus and Trichoderma, and prepared into a liquid product mixture. The liquid product mixture is subjected to aerobic fermentation at about 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com