Biogas residue treatment method and process

A treatment method and biogas residue technology, which is applied to the treatment of biological organic parts, the preparation of organic fertilizers, and fertilizers made from biological waste, can solve the problems affecting the effect of biological fermentation bacteria and the quality of biogas residue fermentation, and achieve improvement The effect of fermentation quality and expansion of bacterial agent volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

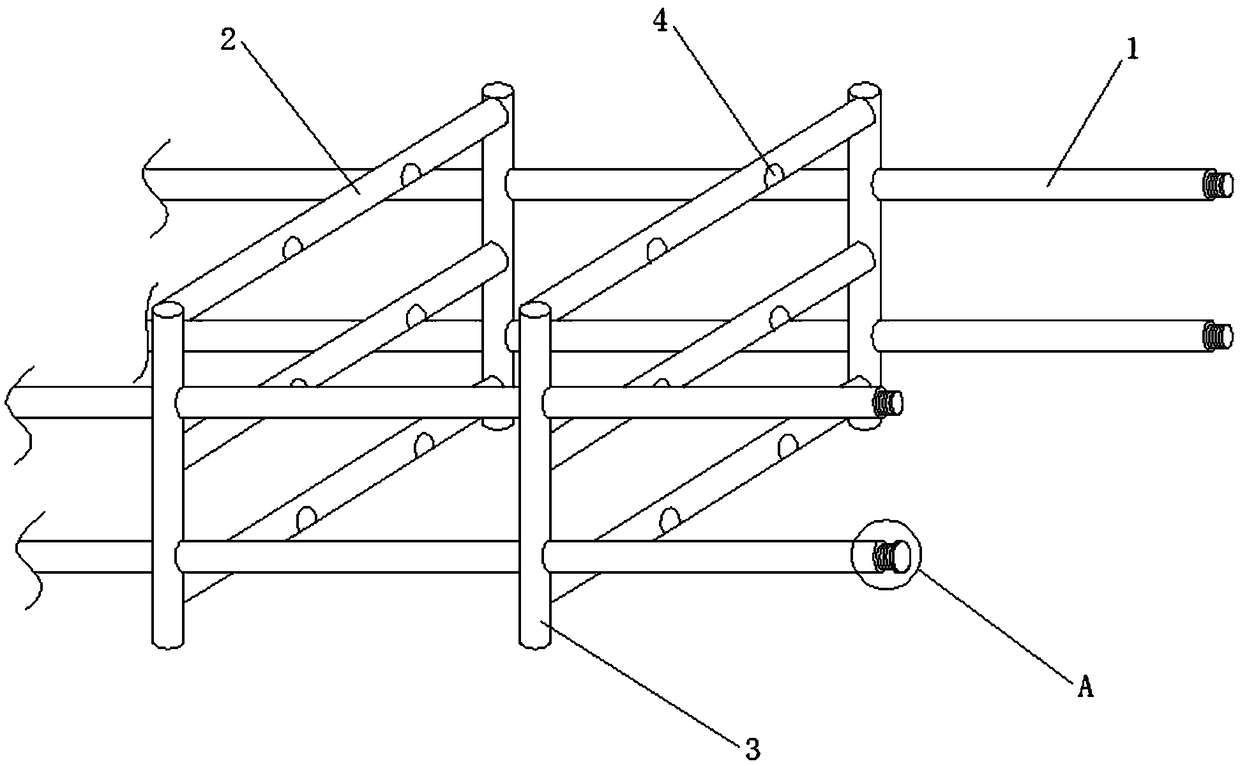

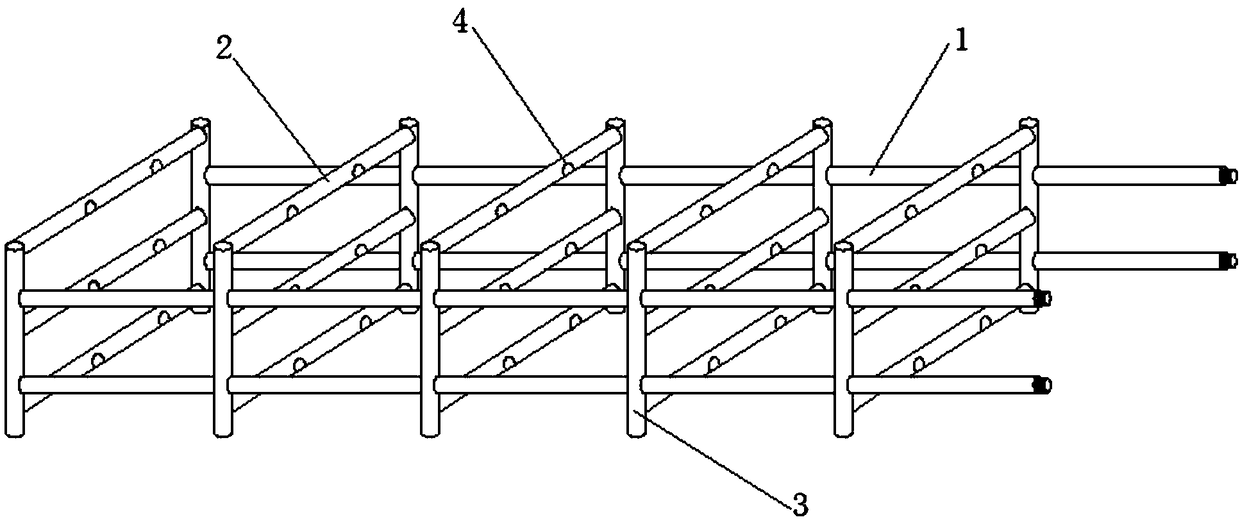

[0048] see Figure 4 , a biogas residue processing method and process, comprising the following steps:

[0049] S1. Biogas residue moisture pre-detection, take the biogas residue to be processed for moisture detection, and the moisture content is 40%;

[0050] S2. Mixing materials, adding adjusting material to biogas residue, mixing and stirring biogas residue and adjusting material according to the weight ratio of 3:1, and then adding 1% quicklime to mix and stir, quicklime can absorb water and release heat, and can promote the fermentation of biogas residue The adjusting material includes mixed powder of straw powder, corn cob powder, rice bran, cotton husk powder and peanut husk powder, which can effectively adjust the air permeability of biogas residue during fermentation. The adjusting material is mixed with microbial fermentation agents, and the adjusting material Mixing with the microbial fermentation agent according to the weight ratio of 10:1 can effectively expand t...

Embodiment 2

[0056] see Figure 4 , a biogas residue processing method and process, comprising the following steps:

[0057] S1. Biogas residue moisture pre-detection, take the biogas residue to be processed for moisture detection, and the moisture content is 65%;

[0058] S2. Mixing materials, adding adjusting material to biogas residue, mixing and stirring biogas residue and adjusting material according to the weight ratio of 3:1, and then adding 1.3% quicklime to mix and stir, quicklime can absorb water and release heat, and can promote the fermentation of biogas residue The adjusting material includes mixed powder of straw powder, corn cob powder, rice bran, cotton husk powder and peanut husk powder, which can effectively adjust the air permeability of biogas residue during fermentation. The adjusting material is mixed with microbial fermentation agents, and the adjusting material Mixing with the microbial fermentation agent according to the weight ratio of 10:1 can effectively expand...

Embodiment 3

[0064] see Figure 4 , a biogas residue processing method and process, comprising the following steps:

[0065] S1. Biogas residue moisture pre-detection, take the biogas residue to be processed for moisture detection, and the moisture content is 68%;

[0066] S2. Mixing materials, adding adjusting material to biogas residue, mixing and stirring biogas residue and adjusting material according to the weight ratio of 3:1, and then adding 1.4% quicklime to mix and stir, quicklime can absorb water and release heat, and can promote the fermentation of biogas residue The adjusting material includes mixed powder of straw powder, corn cob powder, rice bran, cotton husk powder and peanut husk powder, which can effectively adjust the air permeability of biogas residue during fermentation. The adjusting material is mixed with microbial fermentation agents, and the adjusting material Mixing with the microbial fermentation agent according to the weight ratio of 10:1 can effectively expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com