Sintered flux for nickel base strip submerged arc welding

A technology of sintering flux and submerged arc welding, which is applied in the direction of arc welding equipment, welding equipment, welding medium, etc., can solve the problems such as no invention patents have been retrieved, achieve excellent surfacing welding process, high weld bead forming quality, and reduce harmful impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

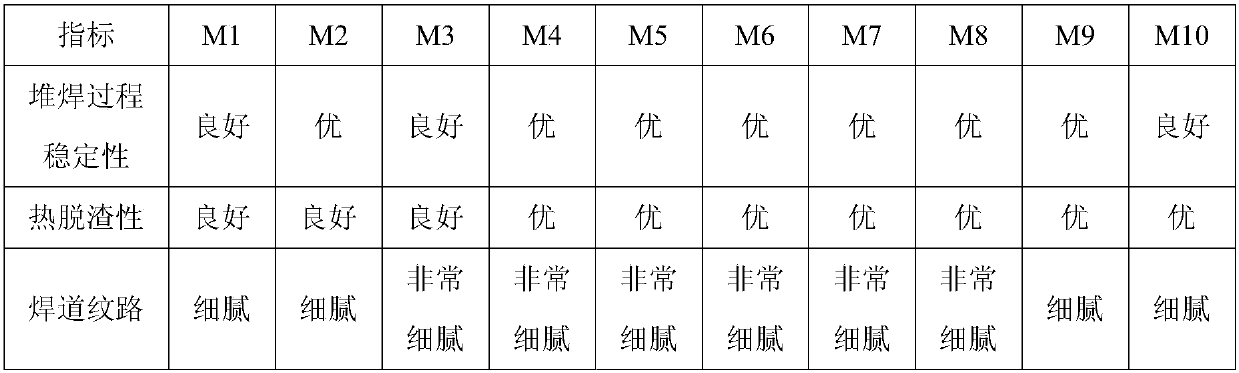

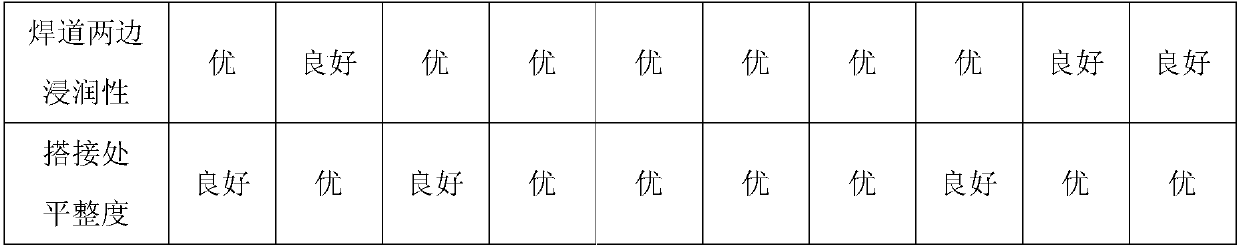

[0042] According to the composition of the dry powder in the sintered flux designed in the present invention, 10 kinds of dry powders are prepared and corresponding to 10 kinds of water glass additions, and the numbers are M1-M10.

[0043] See Table 1 for the weight percentages and water glass additions of 10 kinds of sintered flux dry powder components, and the flux preparation method is as follows:

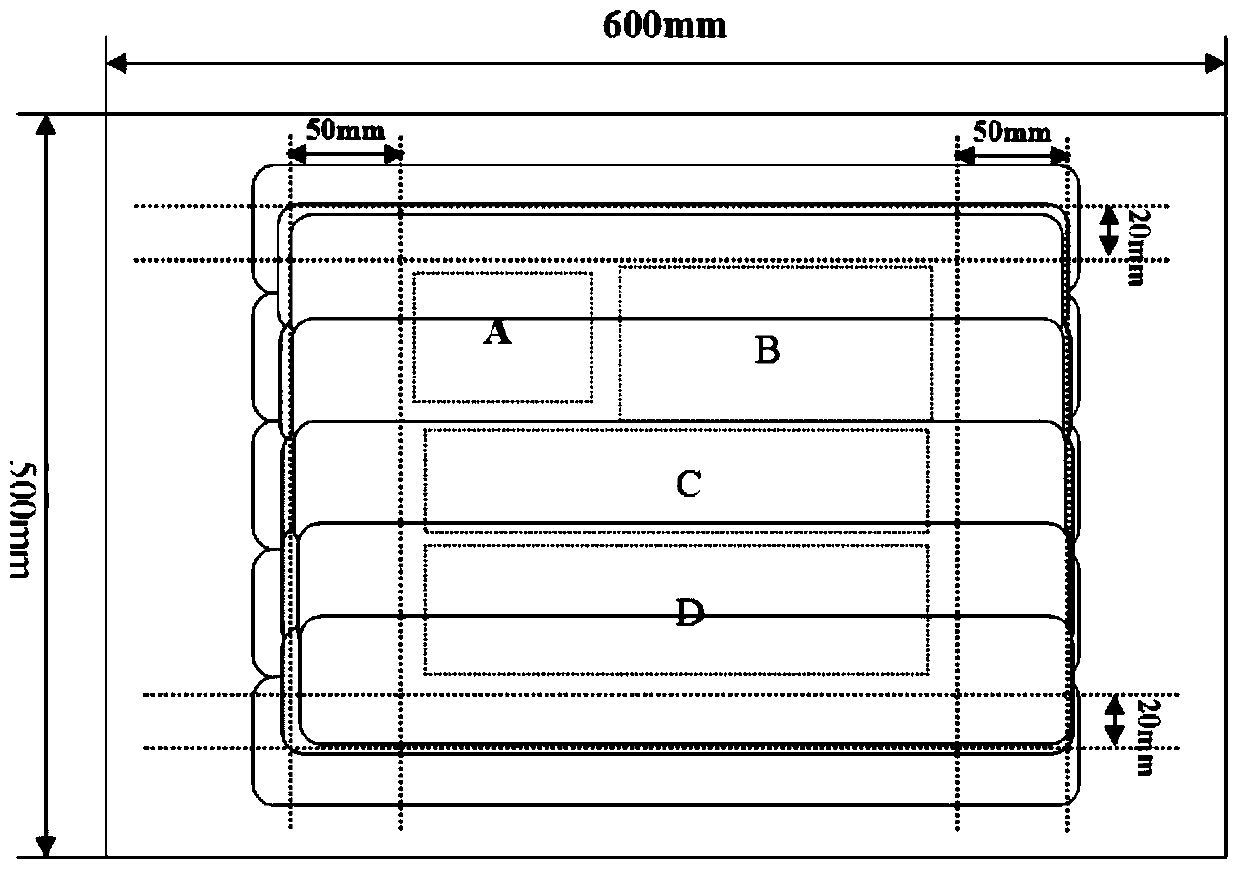

[0044] Proportionally weigh the required dry powder for sintered flux according to the formula. After rechecking the total weight, put it into a dry mixer for 20 minutes. After dry mixing evenly, pour it into a wet mixer, and add the required amount of water glass for wet mixing. After wet mixing evenly, the wet powder is sent to the granulation tray through the conveyor belt for granulation. After the granulation is completed, it is sent to the low-temperature drying furnace through the conveyor belt, dried at 250-300°C for 30-50 minutes, and then lifted by the elevator and siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com