A diatom-based porous ceramic used as a sludge biological drying conditioner and its preparation method

A porous ceramic and diatom-based technology, which is applied in the field of diatom-based porous ceramics and its preparation, can solve the problems of inability to heat up the pile, poor permeability of the pile, and low free air space, and achieve good chemical stability, High anti-friction ability, water content improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, preparation diatom-based porous ceramics

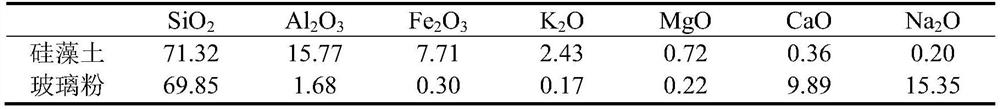

[0023] The main raw material diatomite used in the present invention is purchased from Zhedong diatomite fine product factory in Shengzhou City, Zhejiang Province, and glass powder is purchased from Huayi Mineral Products Processing Factory in Lingshou County. See the table below for sub-analysis (unit: w%):

[0024]

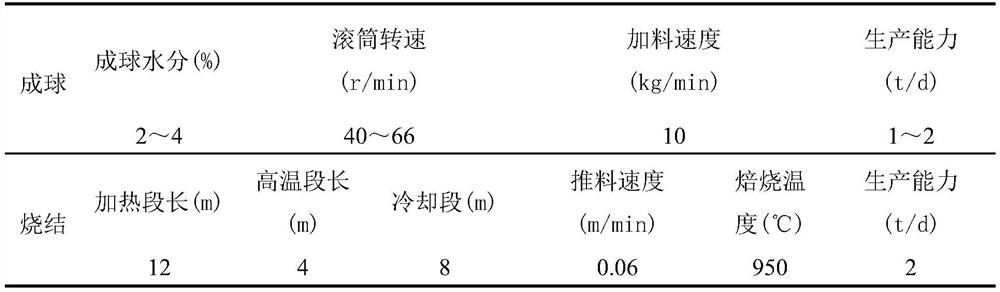

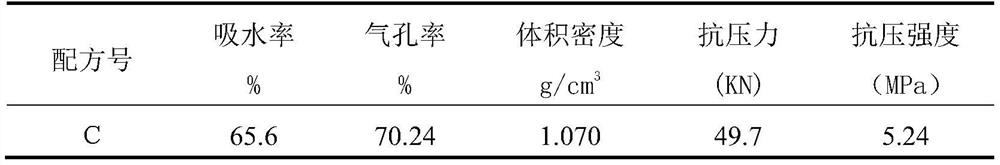

[0025] First, the raw materials with a particle size greater than 200 mesh are transported to a high-pressure suspension roller mill and ground to about 200 mesh. The mass ratio of diatomite to glass powder is 85:15, and the mass of added carbon powder accounts for the total of diatomite and glass powder. 40% of the mass. According to the above ratio (Formula C), the ingredients are sent to the double-cone high-efficiency mixer for mixing, and then enter the drum-type ball forming machine to form a spherical or ellipsoid green body with a diameter of about 2cm, and place it in a ventilated open ...

Embodiment 2

[0032] Embodiment 2, the application example of diatom-based porous ceramics

[0033]The dewatered sludge with a moisture content of 84.1% was mixed with the diatom-based porous ceramic prepared in Example 1 at a mass ratio of 7:3, and the biological drying experiment was carried out in a static batch sludge biological drying reaction system with a reactor volume of about 160L , 1m high, 0.45m inner diameter. The air required in the reaction process is supplied by an air compressor, and six temperature sensors with a length of 20mm are laid on the upper, middle and lower symmetrical positions on both sides of the cylinder, which are used to monitor the temperature change in the reactor online. During the drying process, the system starts up and heats up very quickly. The temperature of the material can be close to 50°C at the 29th hour. At the 41st hour, it reaches the highest temperature of 58.2°C. The heating rate reaches 25°C / d. The moisture removal of the porous ceramic st...

Embodiment 3

[0034] Embodiment 3, the application example of diatom-based porous ceramics

[0035] The dewatered sludge with a moisture content of 84.1% was mixed with the diatom-based porous ceramics prepared in Example 1 at a mass ratio of 5:3, and the biological drying experiment was carried out in the drum sludge biological drying reaction system. The volume of the drum section reactor was 3000L It is 1m long and has an inner diameter of 2m. The inner wall surface is covered with small holes with a diameter of 3mm and a spacing of 5cm for uniform air distribution. The space between the inner and outer walls is evenly divided into 6 parts by the partition, and each part is inserted with an intake branch pipe, a suction branch pipe and a drain pipe, and is connected with the position sensor, and the drain pipe is close to the partition for discharge Condensation water entering between the two walls. When the drum rolls to the proper position, the intake and exhaust valves are automatica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com