Modified fast-growing poplar solid wood floor and modification method thereof

A modification and flooring technology, applied in the direction of wood compression, wood impregnation, impregnated wood, etc., can solve the problems of lack of anti-corrosion function, corrosion of briquette modification agents, shortened service life of pressurized equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

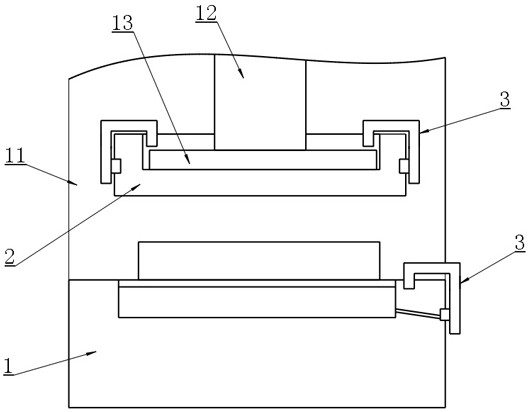

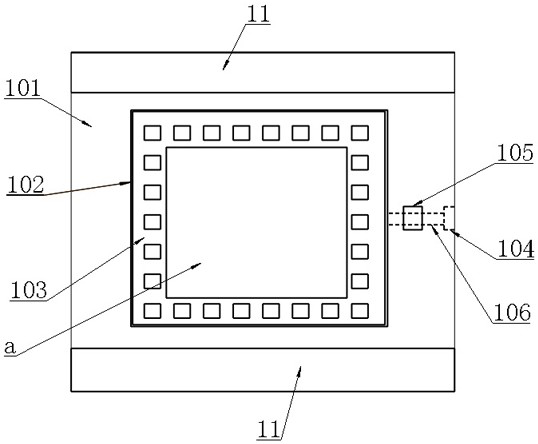

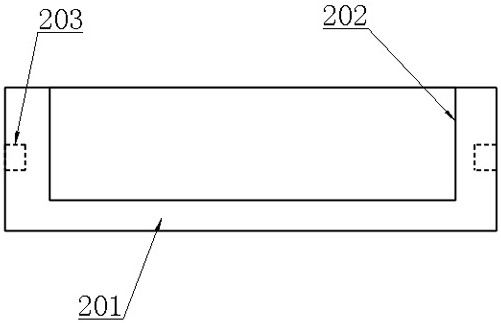

[0029] Example: as attached Figure 1-5 As shown, a modified fast-growing poplar solid wood floor is obtained through the three steps of modifier impregnation, pressure strengthening, and drying and setting. The modifier includes the following components by weight: polyethylene 15-23 parts of diol, 25-30 parts of cetyl acrylate, 9-11 parts of urea-formaldehyde resin, 1.0-3.5 parts of nano-silica powder, and 5-6 parts of dilute hydrochloric acid.

[0030] In this embodiment, the polyethylene glycol is used to increase the density of fast-growing poplar, and the cetyl acrylate is used as an anti-shrinkage agent to ensure that the modified fast-growing poplar solid wood floor has a relatively low shrinkage rate , and the urea-formaldehyde resin is used as a stiffening agent for wood modification to ensure the self-hardness of the modified fast-growing poplar solid wood floor, and the nano-silica powder is used to fill in the gaps in the fast-growing poplar wood. In order to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com