Noise-reduction heat-insulation wall material, preparation method thereof, noise-reduction heat-insulation building block and manufacturing method thereof

A technology for thermal insulation walls and thermal insulation blocks, which is applied in the fields of noise reduction thermal insulation wall materials and their preparation, noise reduction thermal insulation blocks and their production, can solve the problems of affecting the environment, occupying space, etc., and achieve simple process flow and improved The effect of strength, strong compressive and flexural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

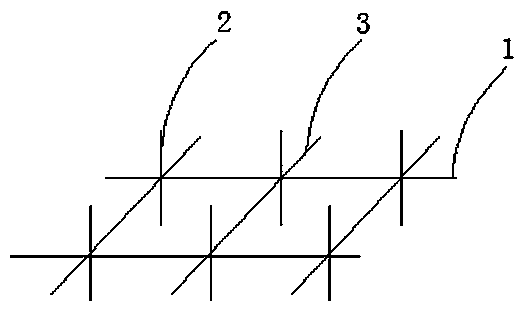

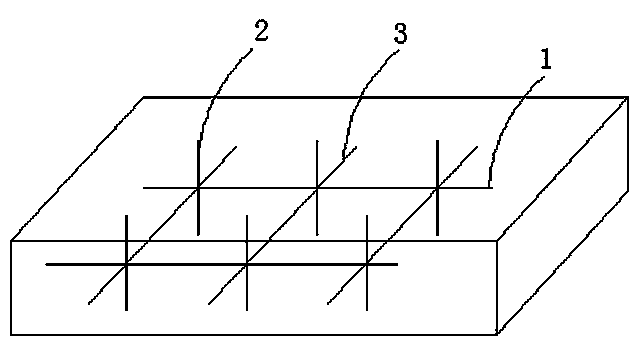

[0061] According to the proportion of construction waste 65%, cement 28%, silica fume 2.5%, graphene oxide 1%, binder 2%, water reducing agent 0.5%, activator 0.5%, dispersant 0.5% ratio mixed material; Then add 35% water of cement quality and stir evenly to obtain mixture A; figure 1 Arranged into the mold in a manner that obtains as figure 2 The diagram of the mesh straw mold is shown. Pour mixture A into figure 2 In the mold, press molding under a certain pressure, remove the mold after 24 hours, and maintain it for 28 days under standard conditions (temperature 20±2°C, relative humidity above 95%) to obtain noise-reducing and heat-insulating wall materials.

[0062] The noise reduction and thermal insulation wall materials are respectively in accordance with the national standard "The Determination of Steady-state Thermal Resistance and Related Properties of Thermal Insulation Materials" GB / T 10294-2008 and "Standard Test for Determination of Sound Absorption and Sound...

Embodiment 2

[0064] According to the proportion of construction waste 69%, cement 25%, silica fume 2%, graphene oxide 0.8%, binder 2%, water reducing agent 0.4%, activator 0.4%, dispersant 0.4% ratio mixed material; Then add water with 40% cement mass and stir evenly to obtain mixture A. press the crop stalks figure 1 Arranged into the mold in a manner that obtains as figure 2 The diagram of the mesh straw mold is shown. Pour mixture A into figure 2 In the mold, press molding under a certain pressure, remove the mold after 24 hours, and maintain it for 28 days under standard conditions (temperature 20±2°C, relative humidity above 95%) to obtain noise-reducing and heat-insulating wall materials.

[0065] The noise reduction and thermal insulation wall materials are respectively in accordance with the national standard "The Determination of Steady-state Thermal Resistance and Related Properties of Thermal Insulation Materials" GB / T 10294-2008 and "Standard Test for Determination of Soun...

Embodiment 3

[0067] According to the proportion of construction waste 65%, cement 27%, silica fume 3%, graphene oxide 1%, binder 2.5%, water reducing agent 0.5%, activator 0.5%, dispersant 0.5% ratio mixed material; Then add 43% water of cement quality and stir evenly to obtain mixture A; figure 1 Arranged into the mold in a manner that obtains as figure 2 The diagram of the mesh straw mold is shown. Pour mixture A into figure 2 In the mold, press molding under a certain pressure, remove the mold after 24 hours, and maintain it for 28 days under standard conditions (temperature 20±2°C, relative humidity above 95%) to obtain noise-reducing and heat-insulating wall materials.

[0068] The noise reduction and thermal insulation wall materials are respectively in accordance with the national standard "The Determination of Steady-state Thermal Resistance and Related Properties of Thermal Insulation Materials" GB / T 10294-2008 and "Standard Test for Determination of Sound Absorption and Sound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com