Preparation of supported ruthenium-based hydrogenation catalyst and its application in catalytic hydrogenation of aldehyde-containing compounds

A technology of hydrogenation catalysts and aldehyde-based compounds, which is applied in the field of preparation of supported ruthenium-based hydrogenation catalysts, and can solve problems such as activity and selectivity to be improved, dispersion degree reduction, limited load capacity and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

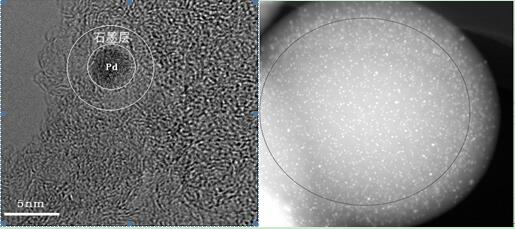

Image

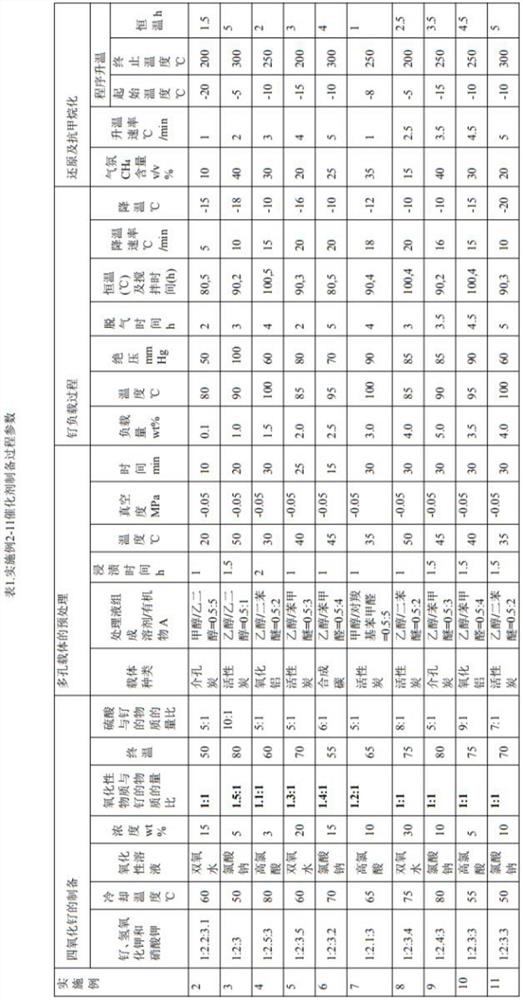

Examples

Embodiment 1

[0046] Configure a ruthenium-based hydrogenation catalyst with a ruthenium loading of 5%. The specific process is as follows:

[0047] 1) Add ruthenium, potassium hydroxide and potassium nitrate into the crucible according to the molar ratio of 1:2.1:3.2, and bake at 650°C until melting for 1 hour. Then add appropriate amount of hot water when cooling to 80°C, and stir until all solids are dissolved.

[0048] 2) Pour the above prepared solution into the three-necked flask A, and drop into 15wt% sodium hypochlorite solution through the funnel, the amount of sodium hypochlorite is 1.5 times that of ruthenium. Then heat up to 80°C, stir, react for about 30 minutes, and then slowly add concentrated sulfuric acid solution with an amount 5 times that of ruthenium substance from the funnel, at this time, golden yellow ruthenium tetroxide gas will be generated.

[0049] 3) Weigh the activated carbon (France Arkema CECA (3sw, particle size: 250-300mesh, N 2 -BET:980m 2 g -1 , ash ...

Embodiment 12

[0068] Put 2000g of glucose and 5g of the ruthenium-based hydrogenation catalyst of Example 1 into the high-pressure hydrogenation reactor, seal the reactor, replace the air and fill it with hydrogen to start stirring, at a temperature of 100°C and a hydrogen pressure of 2.0MPa. Catalytic hydrogenation reaction. Before and during the reaction, the pH value of the hydrogenation solution is monitored online in real time to ensure that the pH value of the hydrogenation solution in the kettle is maintained at 7.0 to 7.5, and the real-time adjustment is carried out by linkage with the concentrated tea juice. After no hydrogen absorption, online sampling and analysis, the reactant content in the hydrogenation solution is 0 and the reaction is stopped. The reaction time is 60 minutes, the conversion rate is 100%, and the selectivity is 99.5%.

Embodiment 13

[0070] Put 2000g of glucose and 1g of the ruthenium-based hydrogenation catalyst of Example 6 into the high-pressure hydrogenation reactor, seal the reactor, replace the air, fill it with hydrogen and start stirring, at a temperature of 90°C and a hydrogen pressure of 5.0MPa. Catalytic hydrogenation reaction. Before and during the reaction, the pH value of the hydrogenation solution is monitored online in real time to ensure that the pH value of the hydrogenation solution in the kettle is maintained at 7.2 to 7.5, and the real-time adjustment is carried out by linkage with the concentrated barley leaf juice. After no hydrogen absorption, online sampling and analysis, the reactant content in the hydrogenation solution is 0 and the reaction is stopped. The reaction time is 65 minutes, the conversion rate is 100%, and the selectivity is 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com