Preparation method of reverse osmosis composite membrane modified with graphene oxide quantum dot-silver phosphate composite

A graphene quantum dot and reverse osmosis composite membrane technology, applied in the field of membrane separation, can solve problems such as shortening membrane life, blocking membrane pores, and membrane being easily polluted, and achieves improved hydrophilicity, high water flux, and efficient sterilization. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

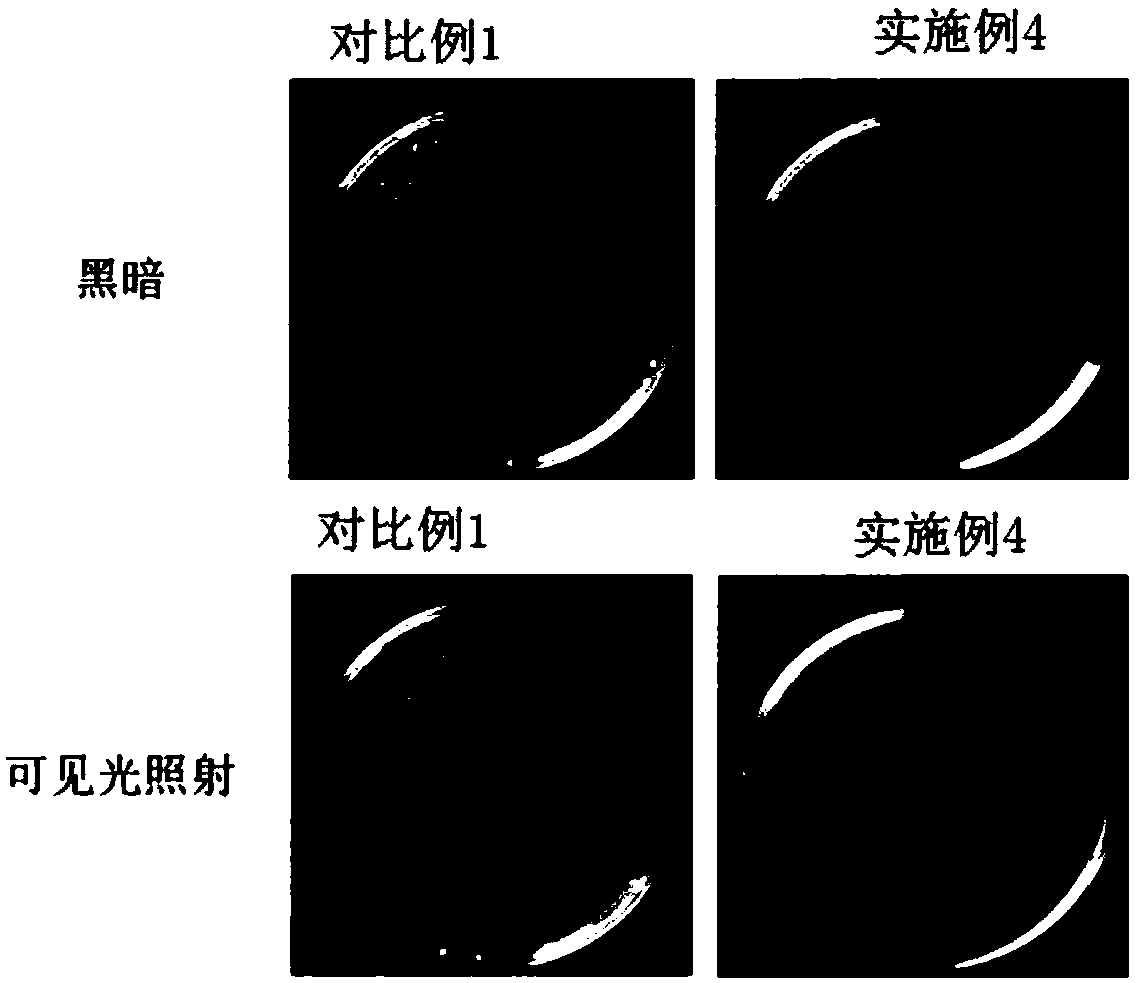

[0038] Embodiment 1 Preparation of graphene oxide quantum dot-silver phosphate composite material

[0039] 10 ml of graphene oxide quantum dot (4 mg / ml) suspension was mixed with 12 ml of silver nitrate (10 mM) aqueous solution and stirred magnetically for 30 minutes, then 0.0144 g of disodium hydrogen phosphate dodecahydrate was added to the mixture and vigorously stirred in the dark After 1 hour, the mixture was centrifuged at 8000 rpm, washed three times with deionized water, and vacuum freeze-dried to obtain a graphene oxide quantum dot-silver phosphate composite material.

Embodiment 2

[0041] A preparation method of a reverse osmosis composite membrane modified by a graphene oxide quantum dot-silver phosphate composite material, comprising steps as follows:

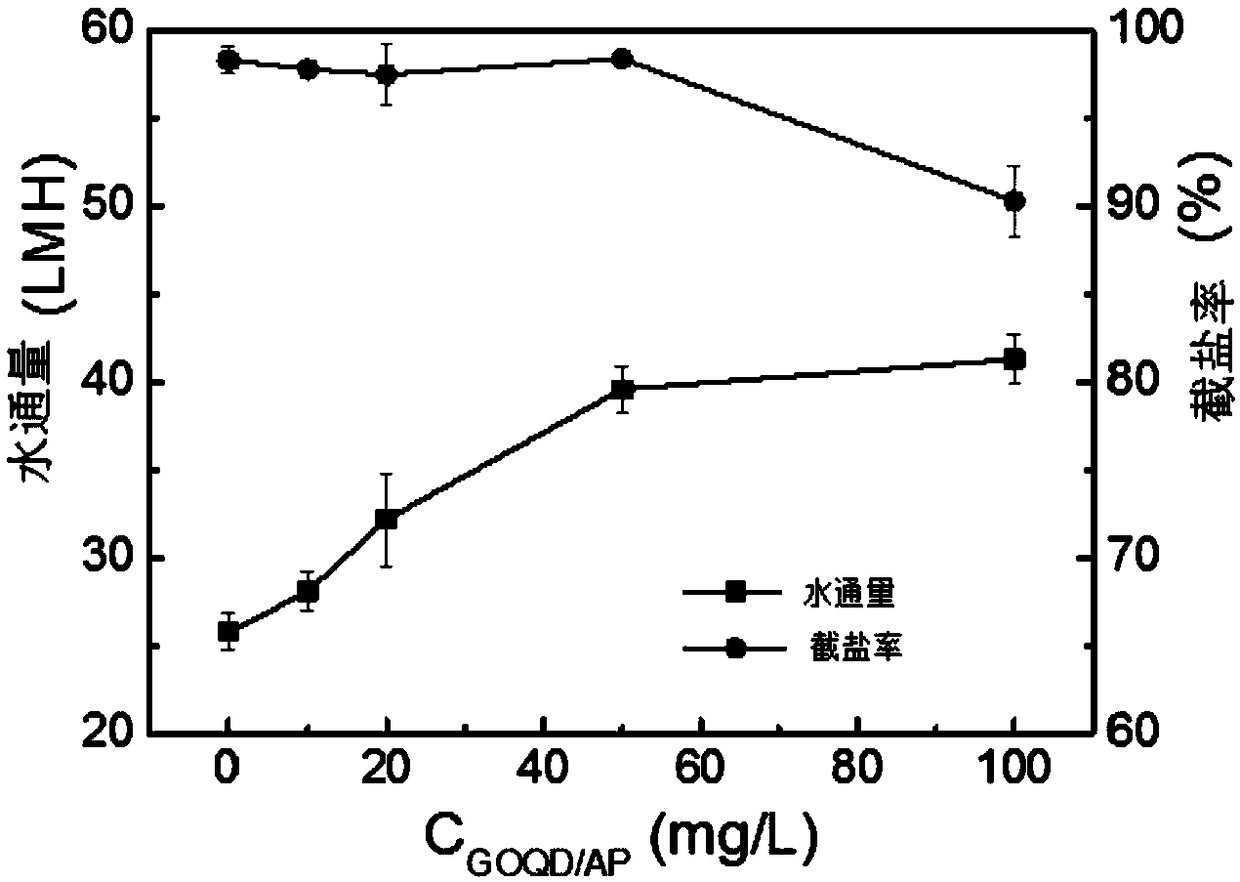

[0042] (1) The graphene oxide quantum dot-silver phosphate composite material of embodiment 1 is added into deionized water, and ultrasonically stirred for 1 hour,

[0043](2) Add m-phenylenediamine in step (1), add a certain amount of sodium dodecylsulfonate after stirring evenly, and obtain an aqueous phase solution after ultrasonic dissolution; graphene oxide quantum dot-silver phosphate in the aqueous phase solution The mass concentration of the composite material is 0.001% (w / v), the mass concentration of m-phenylenediamine is 2% (w / v), and the mass concentration of sodium dodecylsulfonate is 0.15w% (w / v).

[0044] (3) A certain amount of trimesoyl chloride is added to n-hexane to make the concentration 0.1w / v%, and the oil phase solution is obtained after ultrasonication;

[0045] (4) Put the wat...

Embodiment 3

[0048] A preparation method of a reverse osmosis composite membrane modified by a graphene oxide quantum dot-silver phosphate composite material, comprising steps as follows:

[0049] (1) The graphene oxide quantum dot-silver phosphate composite material of embodiment 1 is added into deionized water, and ultrasonically stirred for 1 hour,

[0050] (2) Add m-phenylenediamine in step (1), add a certain amount of sodium dodecylsulfonate after stirring evenly, and obtain an aqueous phase solution after ultrasonic dissolution; graphene oxide quantum dot-silver phosphate in the aqueous phase solution The mass concentration of the composite material is 0.002% (w / v), the mass concentration of m-phenylenediamine is 2% (w / v), and the mass concentration of sodium dodecylsulfonate is 0.15w% (w / v).

[0051] (3) A certain amount of trimesoyl chloride is added to n-hexane to make the concentration 0.1w / v%, and the oil phase solution is obtained after ultrasonication;

[0052] (4) Put the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com