Composition

A composition, compound technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

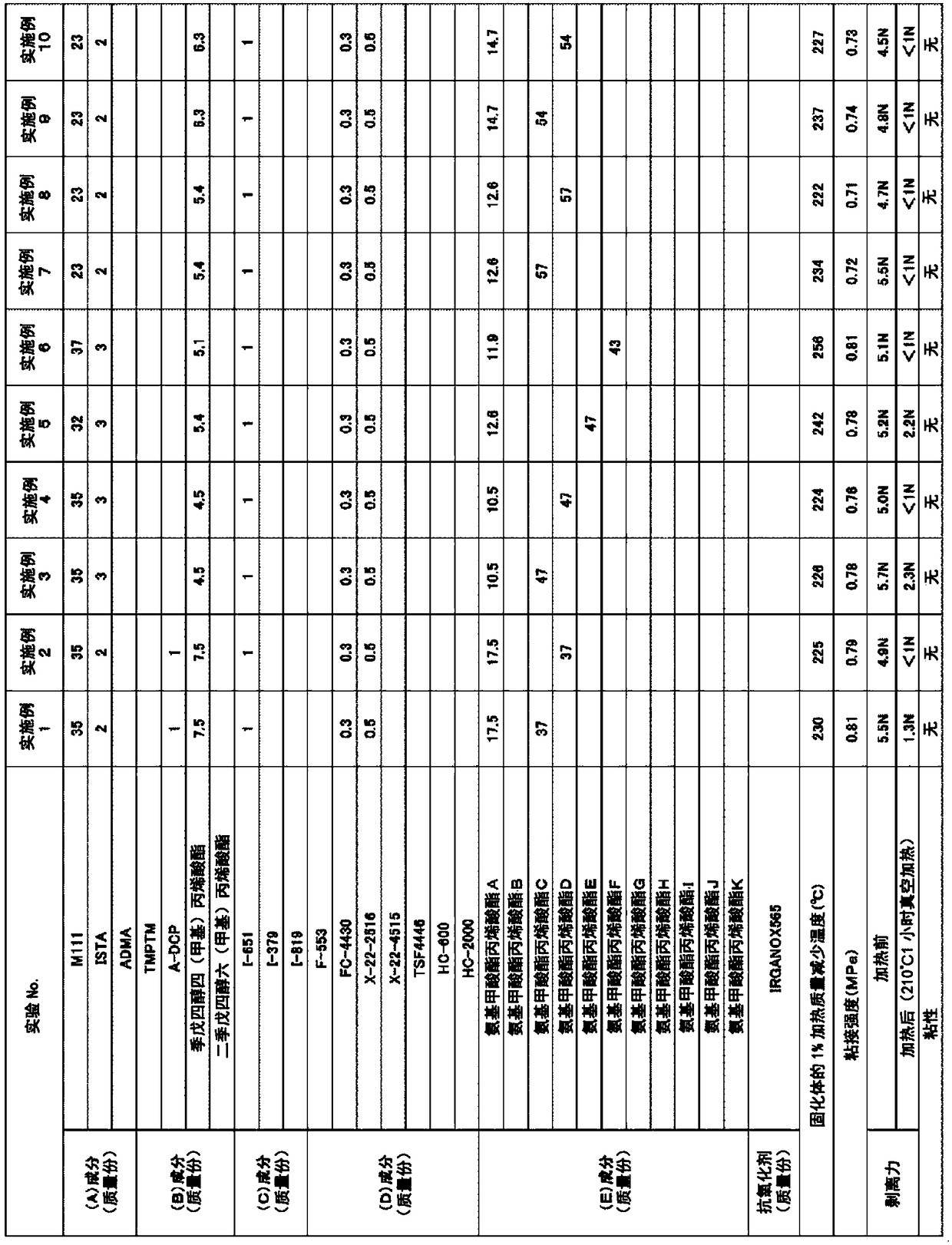

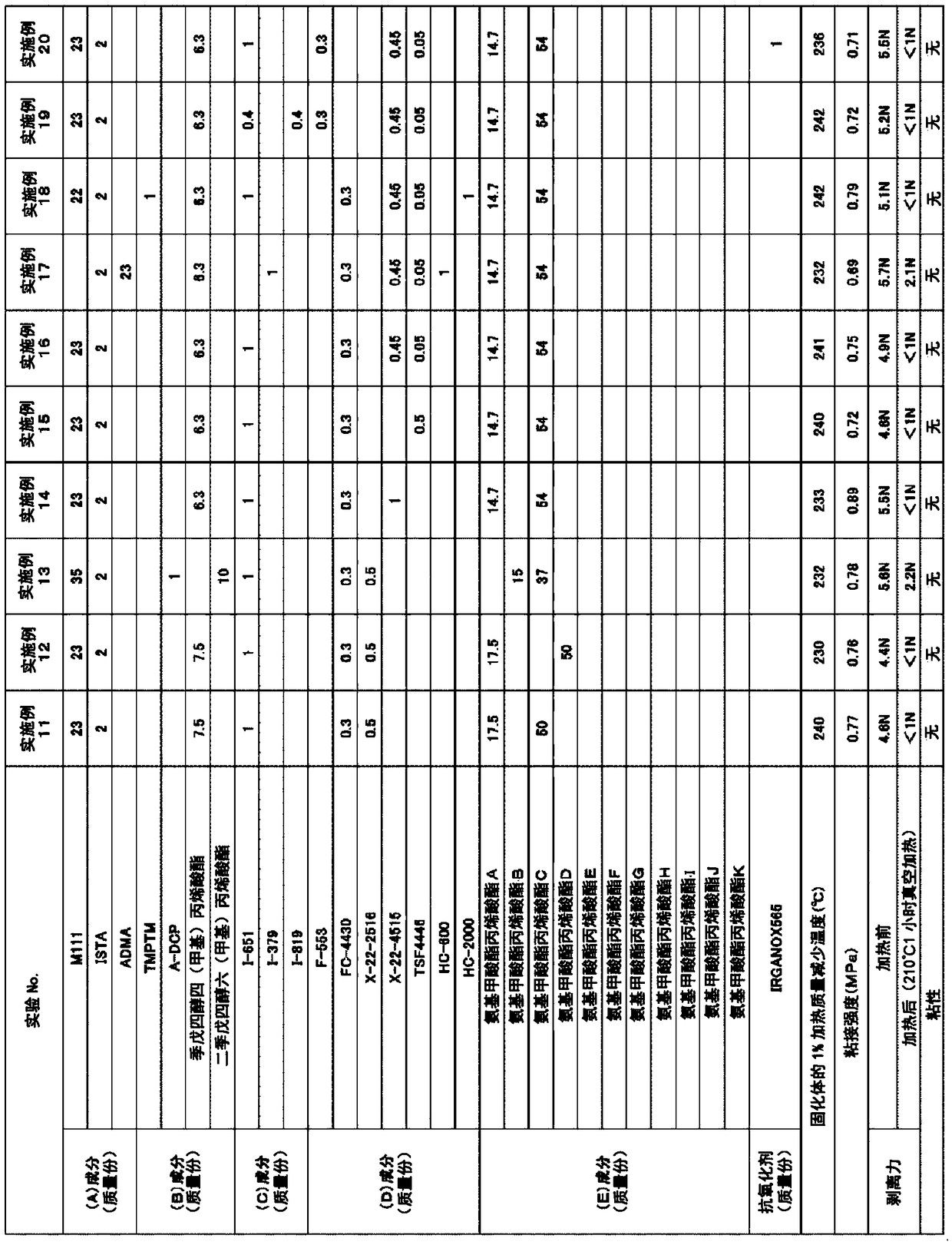

[0121] Hereinafter, the present invention will be described in more detail with reference to experimental examples, but the present invention is not limited to these experimental examples.

experiment example

[0123] Unless otherwise specified, the experiment was performed at 23° C. and a humidity of 50%. Curable resin compositions of the compositions shown in Tables 1 to 4 were prepared and evaluated.

[0124] As each component in the curable resin composition described in the experimental example, the following compounds were selected.

[0125] As (A) monofunctional (meth)acrylate having a number average molecular weight of less than 1,000, the following compounds are selected.

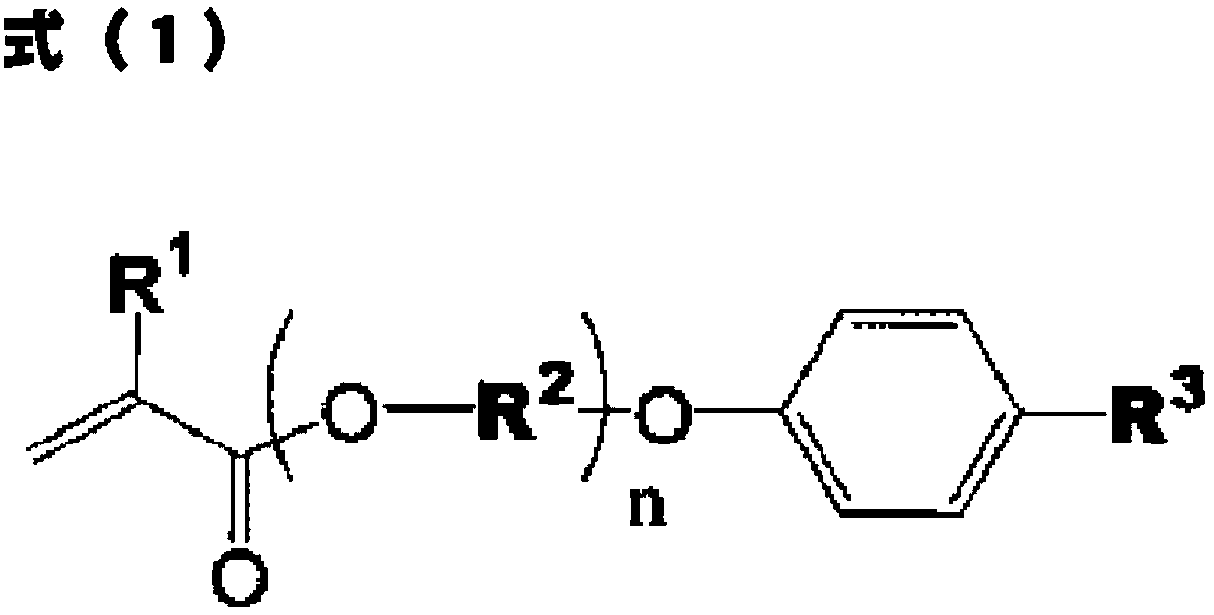

[0126] (A-1) Nonylphenol ethylene oxide modified acrylate ("M-111" manufactured by Toagosei Co., Ltd., the structure is in formula (1), R 1 is a hydrogen atom, R 2 is ethylene, R 3 is nonyl, n is 1)

[0127] (A-2) Isostearyl acrylate ("ISTA" manufactured by Osaka Organic Co., Ltd.)

[0128] (A-3) 1-adamantyl methacrylate ("ADMA" manufactured by Osaka Organic Co., Ltd.)

[0129] As the polyfunctional (meth)acrylate (B) whose number average molecular weight is less than 1,000, the following compounds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com