Process for ammonia production

A process, a technology for synthesizing ammonia, applied in the preparation/separation of ammonia, production of bulk chemicals, ammonia compounds, etc., can solve the problems of incomplete recovery of reaction heat, increase in size of pressure vessel, complex mechanical design, etc., to increase the conversion rate per pass Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

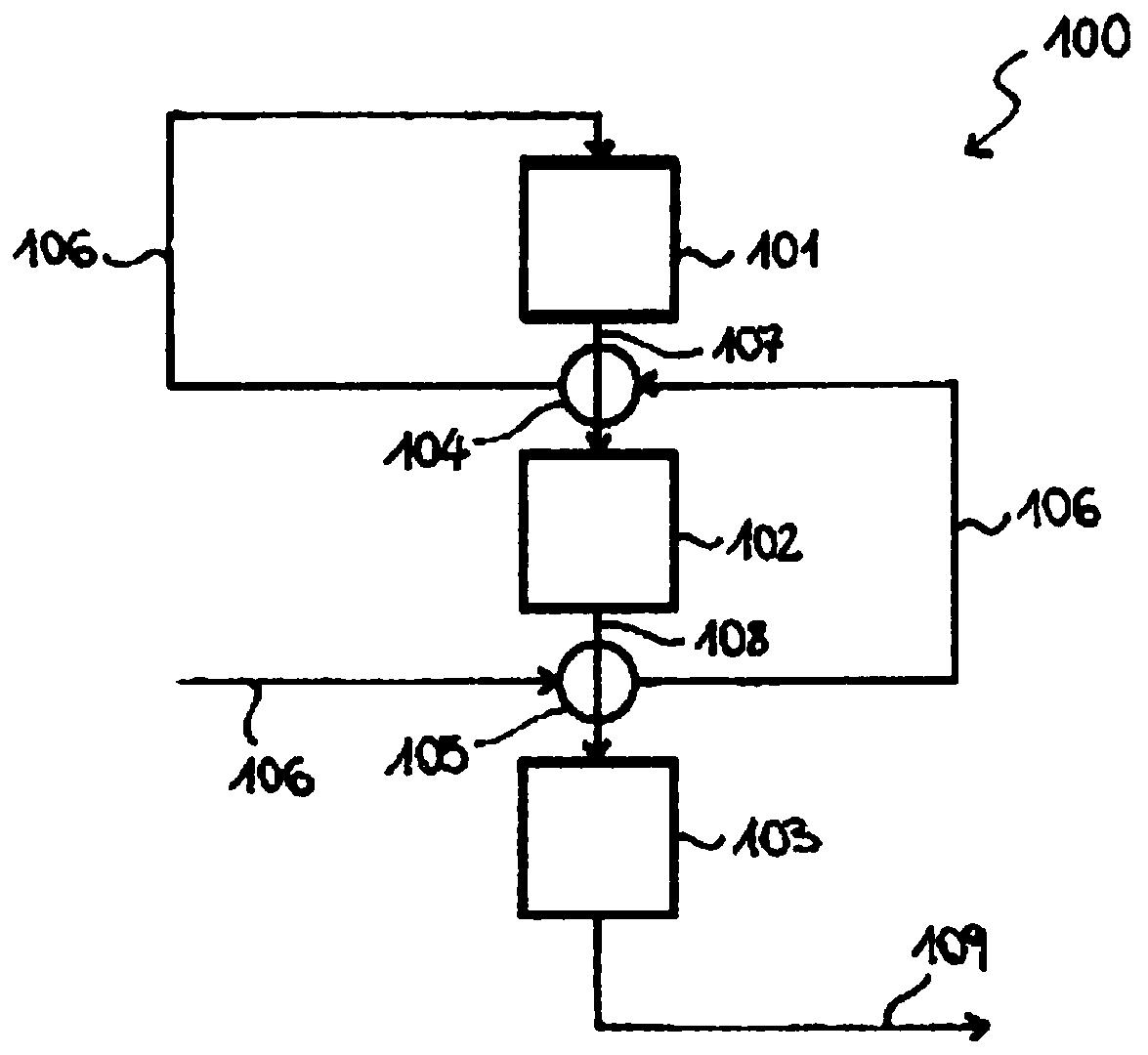

[0085] FIG. 1 shows a prior art multi-bed reactor 100 . The reactor 100 comprises: three adiabatic catalyst beds 101 , 102 , 103 arranged in series, a first interbed heat exchanger 104 and a second interbed heat exchanger 105 .

[0086] The operation of the reactor 100 will be described below.

[0087] Fresh make-up gas 106 passes through the second heat exchanger 105 (where it is preheated by the effluent of the second bed 102) and then passes through the first heat exchanger 104 (where it is preheated by the effluent of the first bed 101). The makeup gas 106 thus preheated enters the first bed 102 where it is partially reacted to provide a first ammonia-containing stream 107 . The stream 107 is cooled in the first heat exchanger 104 and the cooled effluent enters the second bed 102 where it reacts further to provide a second ammonia-containing stream 108 . Similarly, the stream 108 is cooled in a second heat exchanger 105 before entering the third bed 103 which provides an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com