25G optical module

A technology of optical modules and movable blocks, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of chip performance degradation, volume thermal density increase, failure, etc., to achieve more heat generation, improve heat dissipation efficiency, and increase heat dissipation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

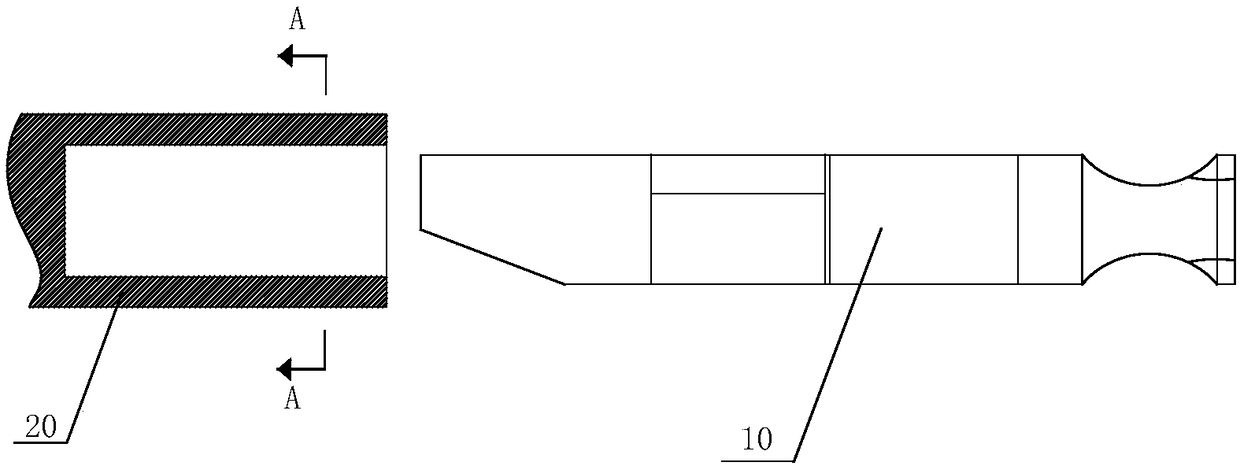

[0038] In the drawings, the optical module body 10 is inserted into the housing 20 as a working state, and the optical module body 10 is not inserted into the housing 20 as a non-working state.

[0039] Such as figure 1 As shown, a 25G optical module includes an optical module main body 10 and a casing 20 into which the optical module main body 10 is inserted with an opening at one end. The optical module main body 10 may be sleeved inside the casing 20 or not. , Placed separately.

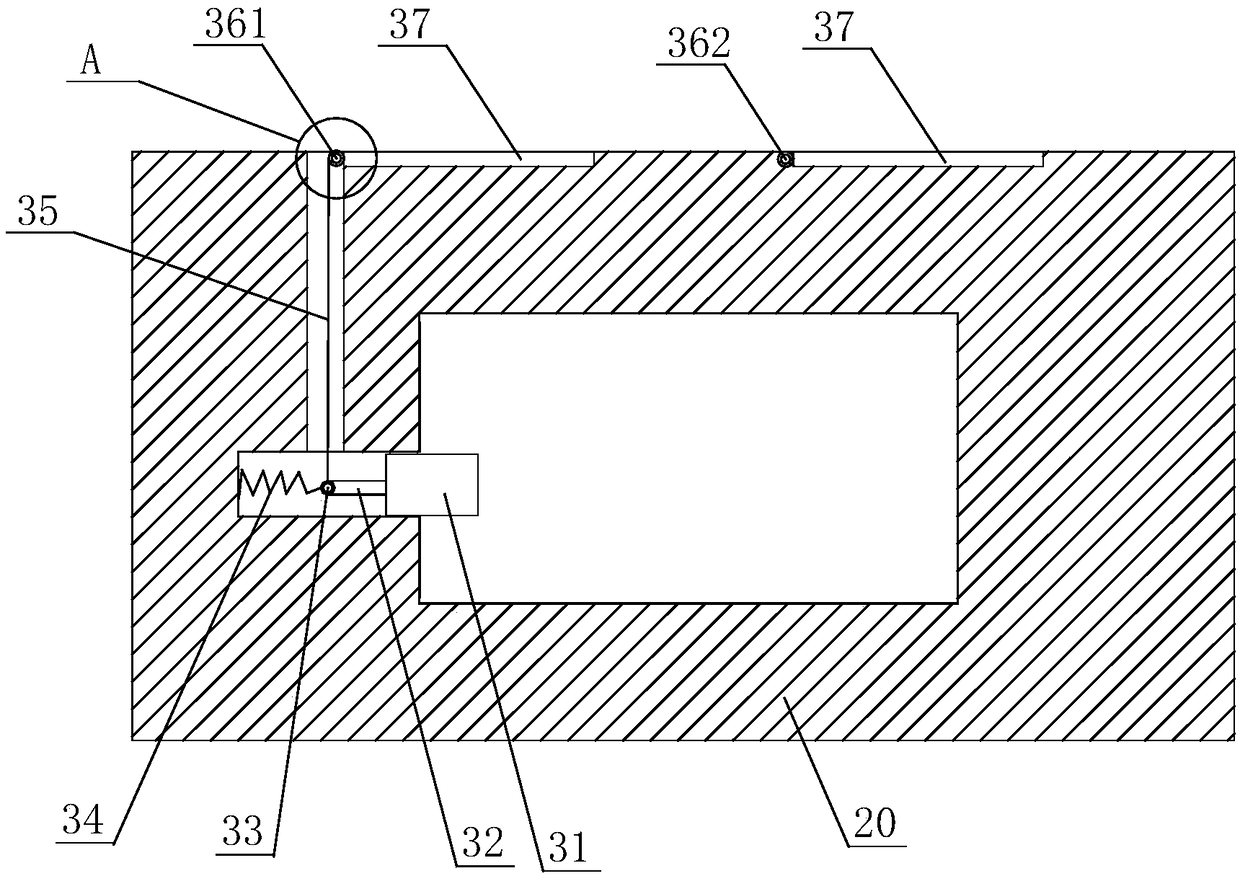

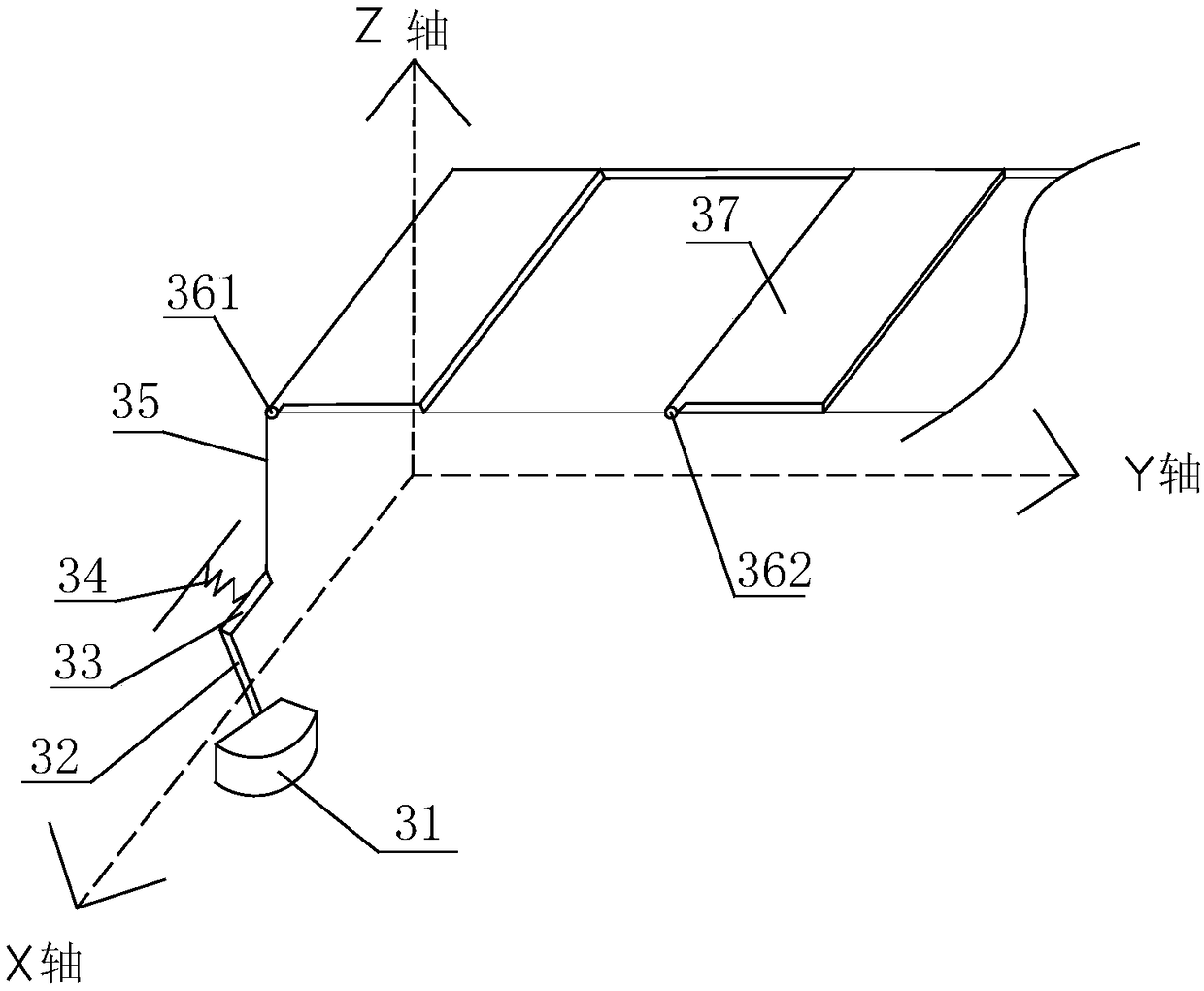

[0040] Such as Figure 2~5 As shown, the housing 20 includes a base 21 with a cavity inside, and the cavity can be used for the optical module body 10 to enter and exit. A heat dissipation portion 22 is provided above the base 21. The base 21 and the heat dissipation portion 22 are actually a whole, but are divided into two parts for convenience of description.

[0041] An installation channel is provided on at least one side wall near the opening of the base 21. The movable block 31 is installed insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com