Heating floor tile

A floor tile and heating technology, applied in the field of heating floor tiles, can solve problems such as unreasonable structural design, increase maintenance costs, and reduce production efficiency, so as to improve heat reflection and radiation capabilities, good heat insulation functions, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

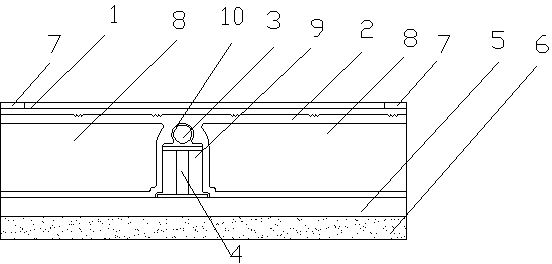

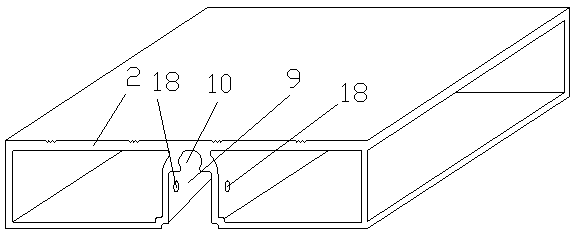

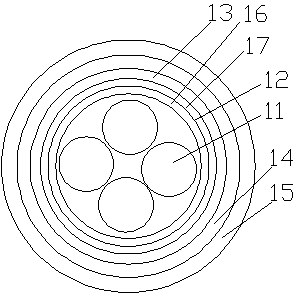

[0036] A heated floor tile, comprising a solid wood board 1 and an aluminum frame 2, the solid wood board 1 is located above the aluminum frame 2, the lower surface of the solid wood board 1 is fixedly connected to the upper surface of the aluminum frame 2, and also includes a heating cable 3 and a support 4. Reflective film 5 and foam concrete 6, the four corners of the upper surface of the solid wood board 1 are bonded with ceramic plates 7, the aluminum frame 2 is integrally formed, and the lower surface of the aluminum frame 2 protrudes from the upper surface to form a There are cavities 8 on both sides of the accommodating groove. The accommodating groove is composed of a supporting groove 9 and a groove 10 above the supporting groove 9. The heating cable 3 is embedded in the groove 10. The The support member 4 is clamped in the support card slot 9, the cross section of the support member 4 is in the shape of "I", the reflective film 5 is fixedly connected with the lower s...

Embodiment 2

[0039] A heated floor tile, comprising a solid wood board 1 and an aluminum frame 2, the solid wood board 1 is located above the aluminum frame 2, the lower surface of the solid wood board 1 is fixedly connected to the upper surface of the aluminum frame 2, and also includes a heating cable 3 and a support 4. Reflective film 5 and foam concrete 6, the four corners of the upper surface of the solid wood board 1 are bonded with ceramic plates 7, the aluminum frame 2 is integrally formed, and the lower surface of the aluminum frame 2 protrudes from the upper surface to form a There are cavities 8 on both sides of the accommodating groove. The accommodating groove is composed of a supporting groove 9 and a groove 10 above the supporting groove 9. The heating cable 3 is embedded in the groove 10. The The support member 4 is clamped in the support card slot 9, the cross section of the support member 4 is in the shape of "I", the reflective film 5 is fixedly connected with the lower s...

Embodiment 3

[0043] A heated floor tile, comprising a solid wood board 1 and an aluminum frame 2, the solid wood board 1 is located above the aluminum frame 2, the lower surface of the solid wood board 1 is fixedly connected to the upper surface of the aluminum frame 2, and also includes a heating cable 3 and a support 4. Reflective film 5 and foam concrete 6, the four corners of the upper surface of the solid wood board 1 are bonded with ceramic plates 7, the aluminum frame 2 is integrally formed, and the lower surface of the aluminum frame 2 protrudes from the upper surface to form a There are cavities 8 on both sides of the accommodating groove. The accommodating groove is composed of a supporting groove 9 and a groove 10 above the supporting groove 9. The heating cable 3 is embedded in the groove 10. The The support member 4 is clamped in the support card slot 9, the cross section of the support member 4 is in the shape of "I", the reflective film 5 is fixedly connected with the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com