Automatic adjustment method of exhaust back pressure for engine bench test and its adjustment system

An engine bench, exhaust back pressure technology, applied in the direction of engine testing, control/adjustment system, general control system, etc., can solve the problems of long feedback time, narrow adjustment range, low control precision, etc., and achieve wide applicability , Guaranteed accuracy and stability, wide adjustment range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

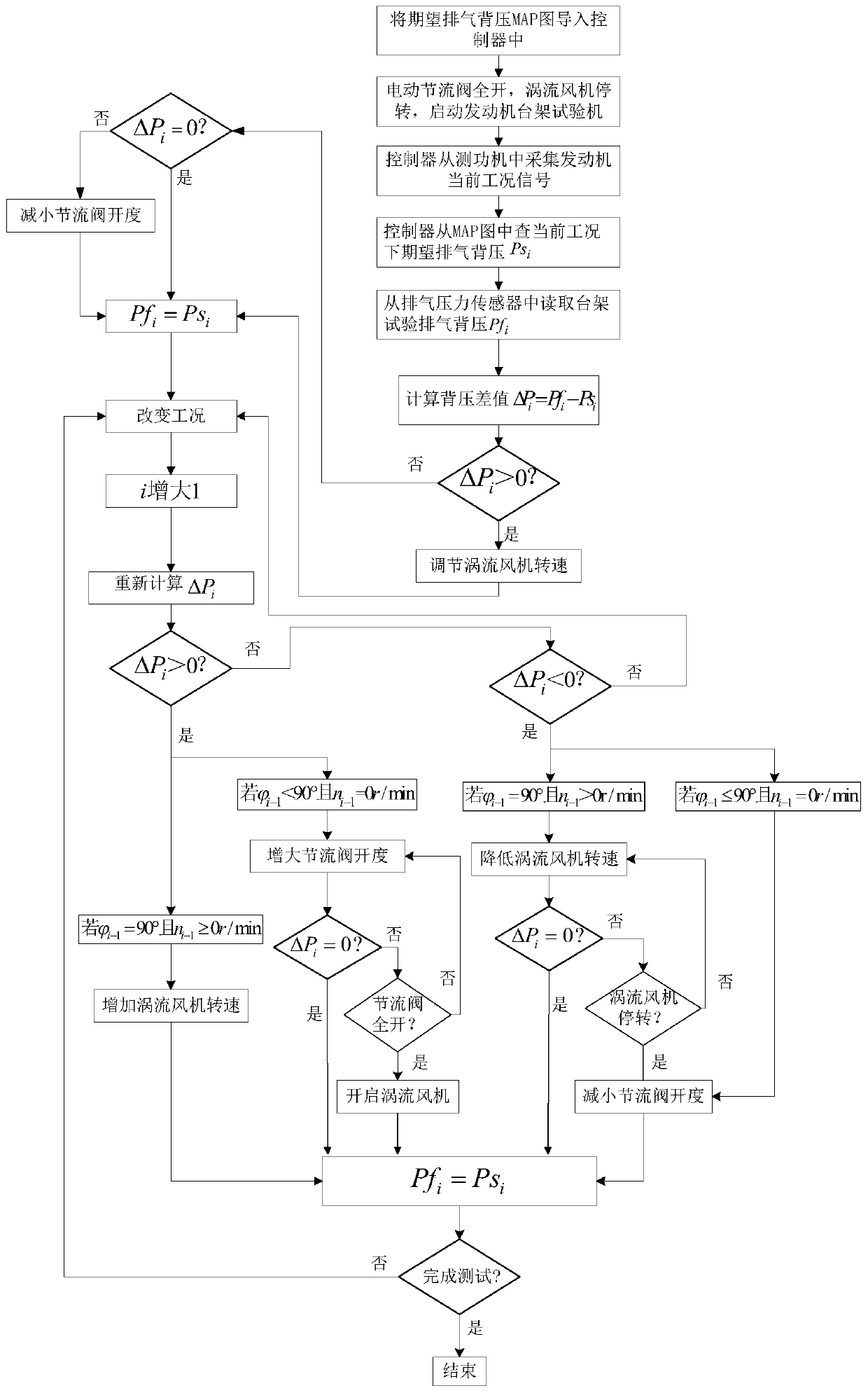

[0024] Below in conjunction with specific example the present invention will be further described

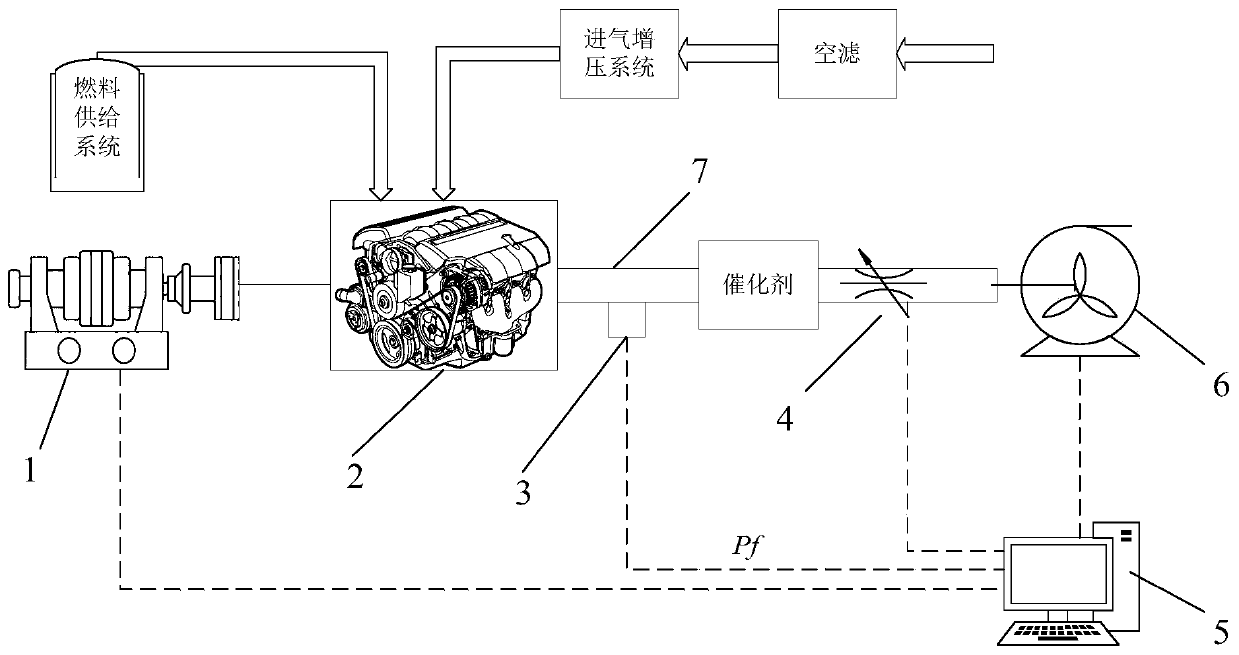

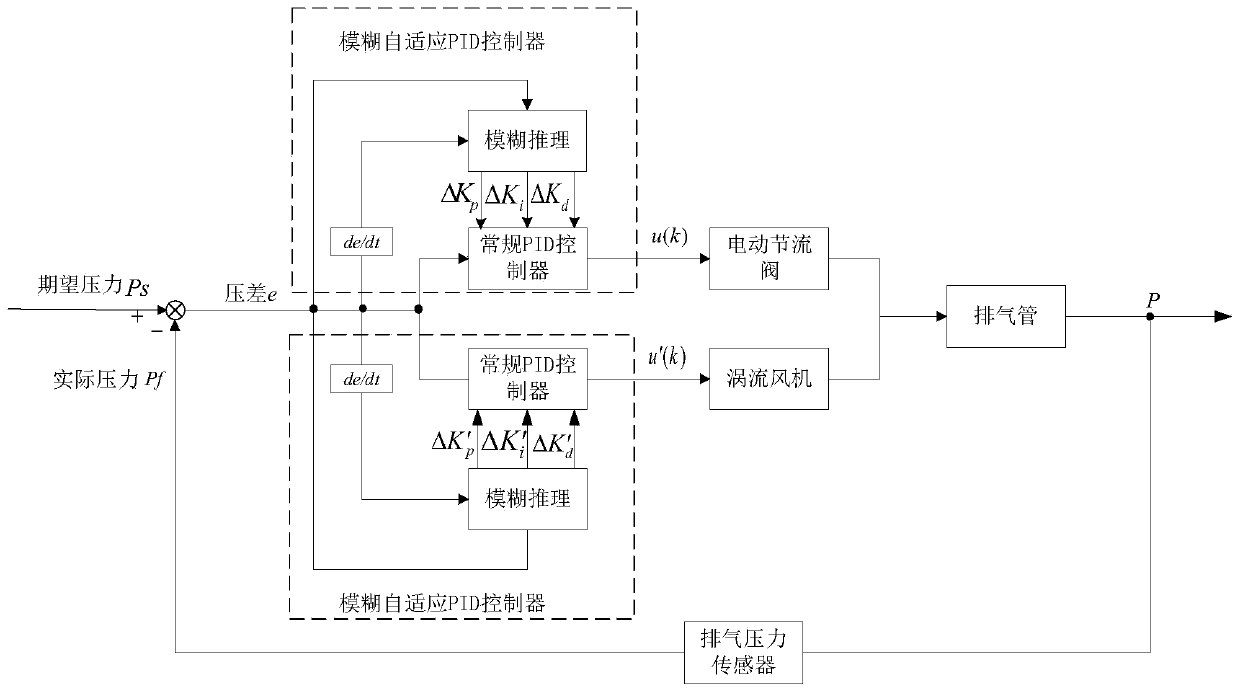

[0025] Such as figure 1As shown, the exhaust back pressure automatic adjustment system for the engine bench test includes a dynamometer 1, an exhaust pressure sensor 3, an electric throttle valve 4, a vortex fan 6 and a fuzzy adaptive PID controller 5. The exhaust pressure sensor 3 is fixed on the input end of the exhaust pipe 7 of the engine 2 through threaded connection, which can not only ensure the sealing of the exhaust pipe but also ensure the accuracy of data measurement; the exhaust pressure sensor 3 measures the exhaust back pressure of the engine , and feed back the measurement data to the fuzzy adaptive PID controller 5 . The dynamometer 1 is connected to the output shaft of the engine 2 through a coupling, and the measured engine speed and load are fed back to the fuzzy adaptive PID controller 5 . The electric throttle valve 4 is fixed on the exhaust pipe 7 near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com