Controlled exhaust backpressure valve for engine

An exhaust back pressure, engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as unsatisfactory, low internal EGR rate, unreachable, etc., to increase temperature, promote CAI combustion, and avoid hold-up. dead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

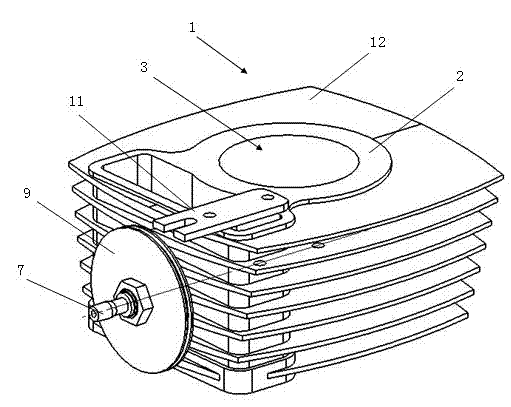

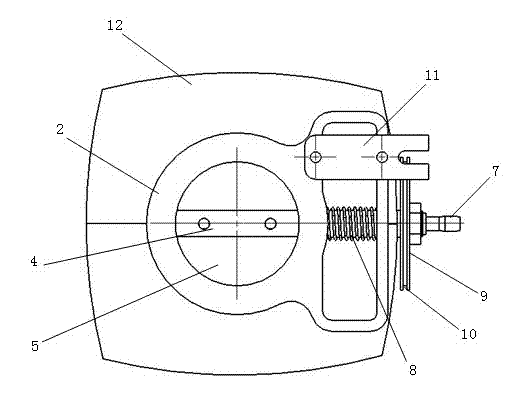

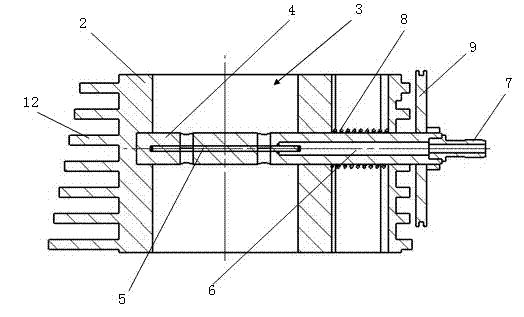

[0024] figure 1 It is a schematic diagram of the structure of the controllable exhaust back pressure valve for the engine of the present invention; figure 2 It is a top view of the controllable exhaust back pressure valve for the engine of the present invention; image 3 It is a longitudinal sectional view of the controllable exhaust back pressure valve for the engine of the present invention.

[0025] Such as figure 1 As shown, in the controllable exhaust back pressure valve 1 for an engine of the present invention, the exhaust back pressure valve 1 is connected to the exhaust manifold of the engine, and is connected in series in the exhaust pipe of the engine, and includes: a body 2, which constitutes The main part of the exhaust back pressure valve, which carries other components of the exhaust back pressure valve; the exhaust passage 3, which penetrates the body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com