Method for modifying medium and low temperature coal tar pitch by hydrogenating styrene-butadiene block copolymer

A technology of block copolymers and hydrogenated styrene, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, rayon manufacturing, etc., can solve the problems of unfavorable reaction control, entrainment loss, environmental pollution, etc., to avoid excessive polymerization and not easy to entrain Good effect of loss and spinning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

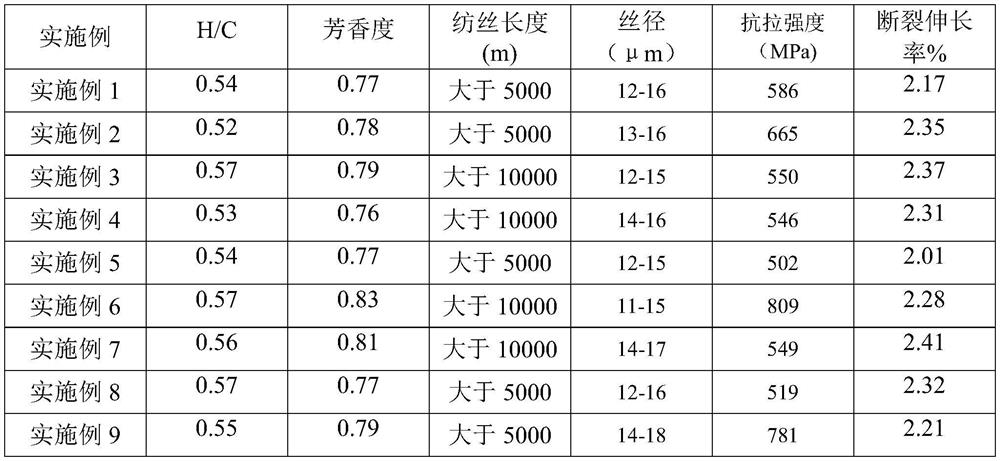

Examples

Embodiment 1

[0023] Medium-low temperature coal tar pitch (softening point: 90°C, ash content 0.2wt%) was crushed to ≤20 mesh, mixed with tetrahydrofuran at a mass ratio of 1:4, extracted and filtered to remove the soluble components of medium-temperature coal tar pitch, and vacuum-dried for 12 hours to obtain The ash content was 0.03 wt% low ash bitumen.

[0024] The obtained low-ash pitch and SEBS were mixed at a ratio of 10:1 (weight ratio), put into the reactor, continuously fed with air at a rate of 20 mL / min g, and heated at a heating rate of 9 °C / min to 340°C, stay for 3 hours. The softening point of the obtained bitumen is 210° C., and the modified bitumen whose softening melting range is 210-245° C. has a total yield of 29%. The modified asphalt is spun at 250°C, the spinning pressure is 0.4MPa, the diameter of the spinneret is 0.3μm, and the winding speed is 200m / min. The asphalt has good spinnability.

Embodiment 2

[0026] Grind medium-low temperature coal tar pitch (softening point: 83°C, ash content 0.18%) to ≤20 mesh, mix with tetrahydrofuran at a mass ratio of 1:5, extract and filter out the soluble components of medium-temperature coal tar pitch, and obtain ash after vacuum drying for 12 hours 0.02% low ash bitumen.

[0027] Mix the obtained low-ash pitch and SEBS at a ratio of 20:1, put it into the reactor, continuously feed air at a rate of 30 mL / min g, heat to 320 °C at a heating rate of 2 °C / min, and stay 1 hour. The obtained asphalt has a softening point of 210°C and a softening melting range of 210-240°C, and the total yield is 31%. The modified asphalt is spun at 245°C, the spinning pressure is 0.5MPa, the diameter of the spinneret is 0.3μm, and the winding speed is 200m / min. The asphalt has good spinnability.

Embodiment 3

[0029] Grind medium-low temperature coal tar pitch (softening point: 94°C, ash content 0.11%) to ≤20 mesh, mix with tetrahydrofuran at a mass ratio of 1:4, extract and filter out the soluble components of medium-temperature coal tar pitch, and obtain ash after vacuum drying for 12 hours 0.016% low ash bitumen.

[0030] Mix the obtained low-ash pitch and SEBS at a ratio of 12:1, put it into the reactor, continuously feed air at a rate of 30 mL / min g, heat to 310 °C at a heating rate of 6 °C / min, and stay 4 hours. The resulting modified asphalt has a softening point of 200° C. and a softening melting range of 200-220° C., and the total yield is 36%. The modified asphalt is spun at 230°C, the spinning pressure is 0.3MPa, the diameter of the spinneret is 0.3μm, and the winding speed is 200m / min. The asphalt has good spinnability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com