Nickel aluminum base-width temperature-range self-lubrication alloy and preparation method thereof

A wide temperature range, self-lubricating technology, used in measuring devices, instruments, mechanical devices, etc., can solve the problem of high friction coefficient, and achieve the effects of high oxidation stability, good structure and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

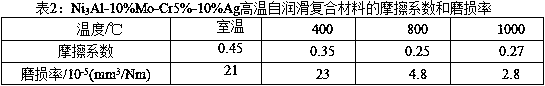

[0027] According to mass percentage Ni 3 75% of Al powder, 10% of Mo powder, 5% of Cr powder, and 10% of Ag powder were weighed as powder materials; the powder materials were dry-mixed in a planetary ball mill with a speed of 250r / min and a ball-to-material ratio of 8:1. The grinding balls are WC balls, and the ball milling time is 6 hours to obtain uniformly mixed Ni 3 Al-Mo-Cr-Ag mixed powder. Then put the mixed powder into a graphite mold coated with BN, put it into a vacuum hot-press sintering furnace for hot-press sintering, and the vacuum degree of the furnace cavity is 10 -2 ~10 -1 Pa, the heating rate is 12°C / min, the sintering temperature is 1100°C, the sintering pressure is 35MPa, and the sintering time is 60min. After sintering, cool down to room temperature with the furnace to obtain dense Ni 3 Al-10%Mo-Cr5%-10%Ag high temperature self-lubricating composite material.

[0028] After testing, the micro-Vickers hardness of the material is 3.5GPa, and the friction...

Embodiment 2

[0031] According to the mass percentage 70%Ni 3 Al powder, 8%Mo powder, 10%Cr powder, 12%Ag powder, weigh the powder materials respectively; place them in a planetary ball mill for dry mixing, the speed is 200r / min, the ball-to-material ratio is 6:1, grind The balls are WC balls, and the ball milling time is 8 hours to obtain uniformly mixed Ni 3 Al-Mo-Cr-Ag mixed powder. Put the mixed powder into a graphite mold coated with BN, and then put it into a vacuum hot-pressing sintering furnace for hot-pressing sintering, and the vacuum degree of the furnace cavity is 10 -2 ~10 -1 Pa, the heating rate is 15°C / min, the sintering temperature is 1150°C, the sintering pressure is 30MPa, and the sintering time is 20min. After sintering, cool down to room temperature with the furnace to obtain dense Ni 3 Al-8%Mo-10%Cr-12%Ag high temperature self-lubricating composite material.

[0032] After testing, the micro-Vickers hardness of the material is 3.4GPa, and the friction coefficient a...

Embodiment 3

[0035] According to the mass percentage 75%Ni 3 Al powder, 8%Mo powder, 7%Cr powder, 20%Ag powder, weigh the powder materials respectively, put them into a planetary ball mill for dry mixing, the speed is 300r / min, the ball-to-material ratio is 4:1, mill The balls are WC balls, and the ball milling time is 8 hours to obtain uniformly mixed Ni 3 Al-Mo-Cr-Ag mixed powder. Put the mixed powder into a graphite mold coated with BN, and then put it into a vacuum hot-pressing sintering furnace for hot-pressing sintering, and the vacuum degree of the furnace cavity is 10 -2 ~10 -1 Pa, the heating rate is 15°C / min, the sintering temperature is 1050°C, the sintering pressure is 30MPa, and the sintering time is 30min. After sintering, cool down to room temperature with the furnace to obtain dense Ni 3 Al-8%Mo-7%Cr-20%Ag high temperature self-lubricating composite material.

[0036] After testing, the micro-Vickers hardness of the material is 2.8GPa, and the friction coefficient and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Micro vickers hardness | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com