A kind of extra-furnace refining production method of ultra-pure high-carbon chromium bearing steel

A technology of ultra-pure high-carbon chromium bearings and high-carbon chromium bearing steel, which is applied in the production field of ultra-high-quality bearing steel, can solve the problems of low production efficiency, low steel purity level, high production cost, etc., and prevent molten steel from oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

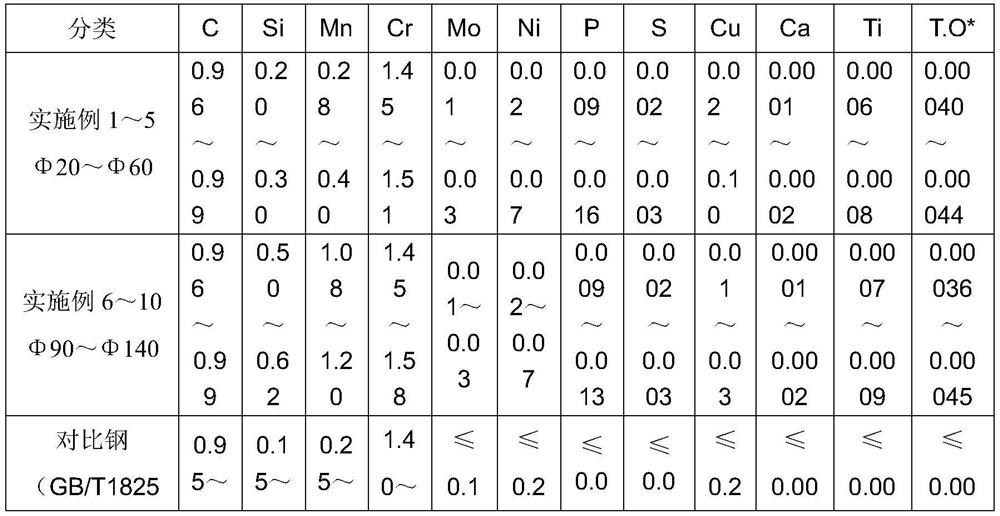

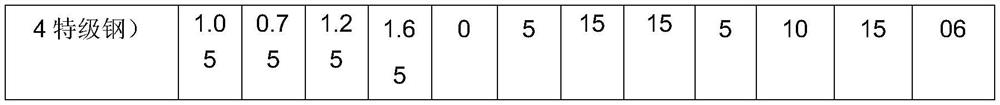

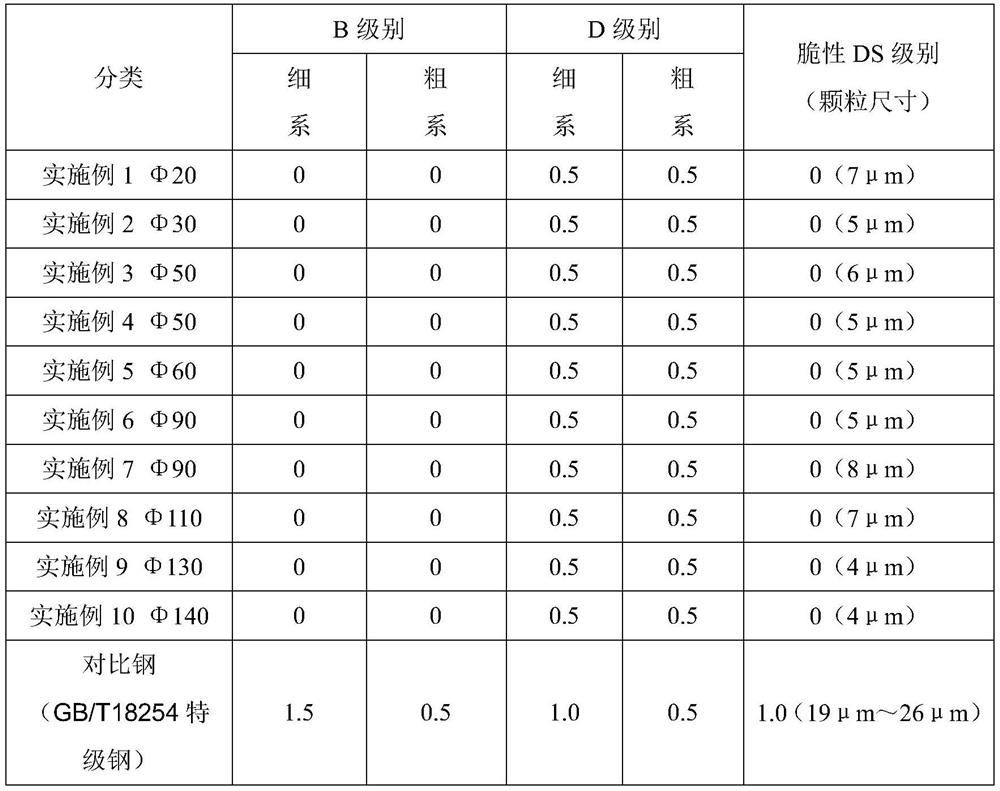

[0031] According to the chemical composition range designed for high-carbon chromium bearing steel, see Table 1, after 100 tons of molten iron pretreatment KR → 100 tons of converter BOF → slag removal RS → 100 tons of refining furnace LF → 100 tons of vacuum degassing furnace RH → large section Continuous casting machine CC→rolling produced 10 furnaces and 8 specifications of the steel of the present invention.

[0032] (1) The ladle, continuous casting tundish and molten steel are made of high refractoriness materials with magnesium content (≥90%), aluminum alloy is used as a deoxidizer, and special slag is used: containing 40-60% CaO, 3-10 %MgO, 3~10%SiO 2 , 20-40%Al 2 o 3 special refining slag, and control the free CaO mole fraction in the refining slag to 40% to 60%;

[0033] (2) The pretreatment of molten iron adopts mechanical agitation and adopts the "one stirring an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com