Kitchen waste fermentation heating system and control method thereof

A technology of food waste and heating system, which is applied in the direction of biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., which can solve the poor fermentation and decomposition effect and efficiency of food waste , Uneven heating effect of kitchen waste, uncontrollable heat conduction direction and other problems, to achieve high energy utilization rate, saving heating energy, accurate temperature adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

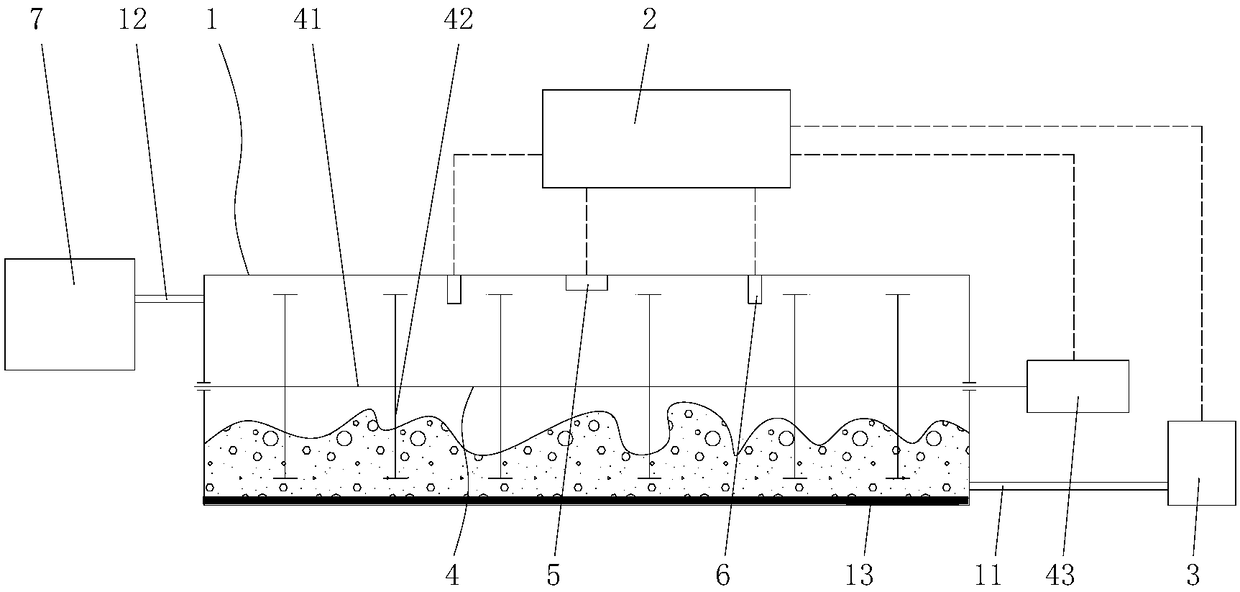

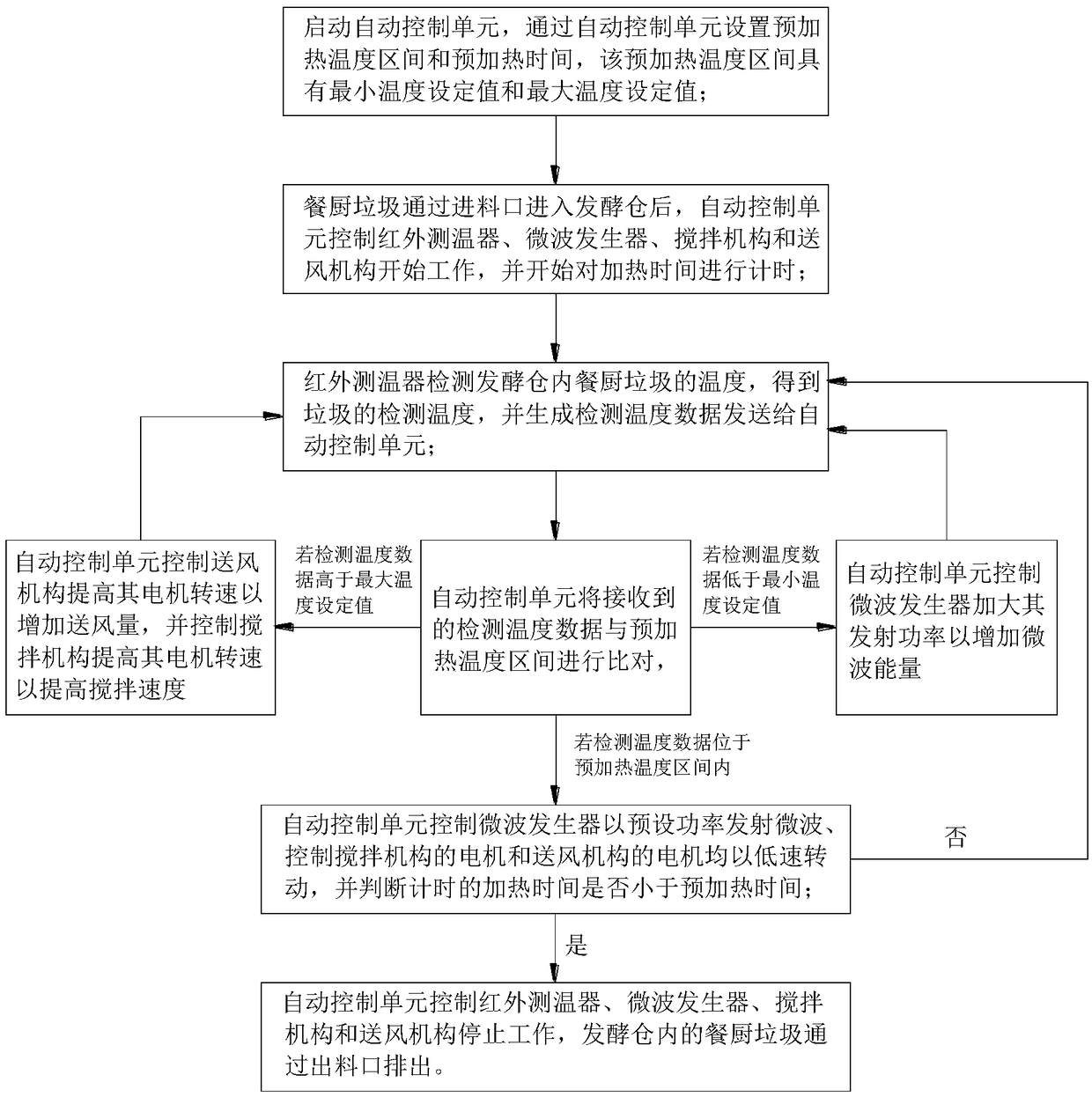

[0028] Such as figure 1 or figure 2 As shown, the food waste fermentation and heating system of the present invention includes a fermentation bin 1, and the fermentation bin 1 is provided with a feed port, a discharge port, an air inlet and an exhaust port conventionally provided in the art, and it also includes The automatic control unit 2 and the air supply mechanism 3, the air supply mechanism 3 communicates with the air inlet through the air intake pipe 11, and is used to deliver fresh cold air to the fermentation chamber 1, the fermentation chamber 1 is formed by metal materials, and the fermentation The bin 1 is provided with a stirring mechanism 4 for stirring the food waste, a microwave generator 5 for heating the food waste, and an infrared thermometer 6 for detecting the temperature of the food waste. The input end of control unit 2 is connected, and is used for sending the detection temperature data that generates to automatic control unit 2, and the output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com