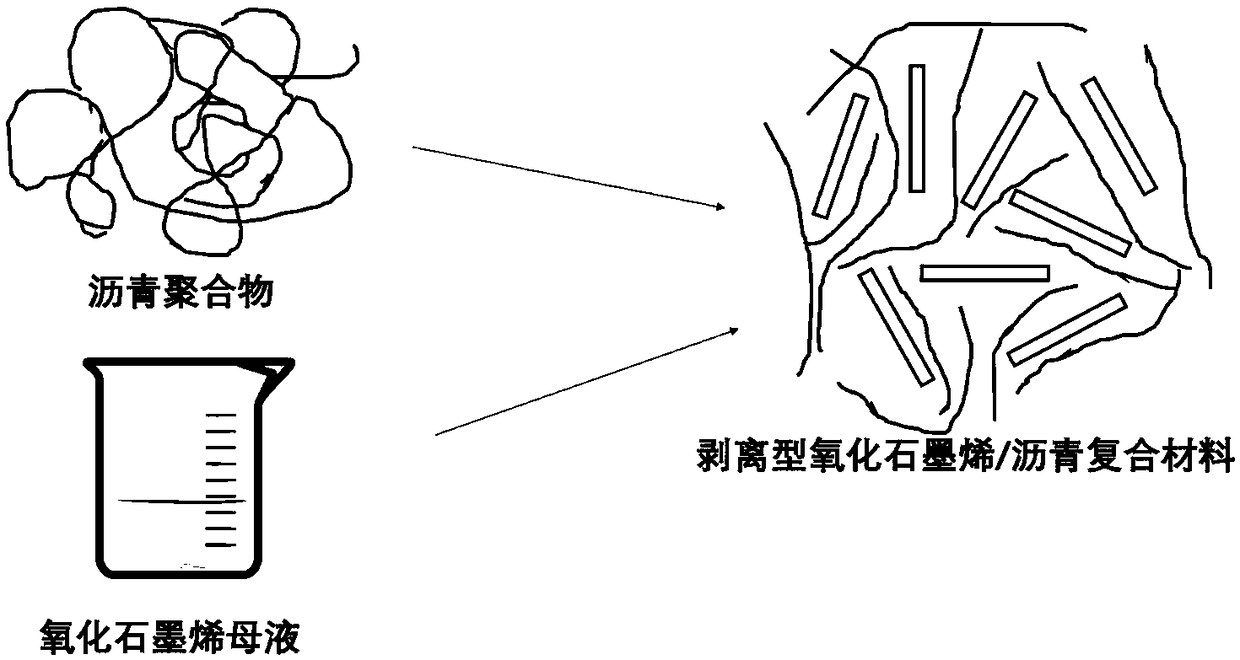

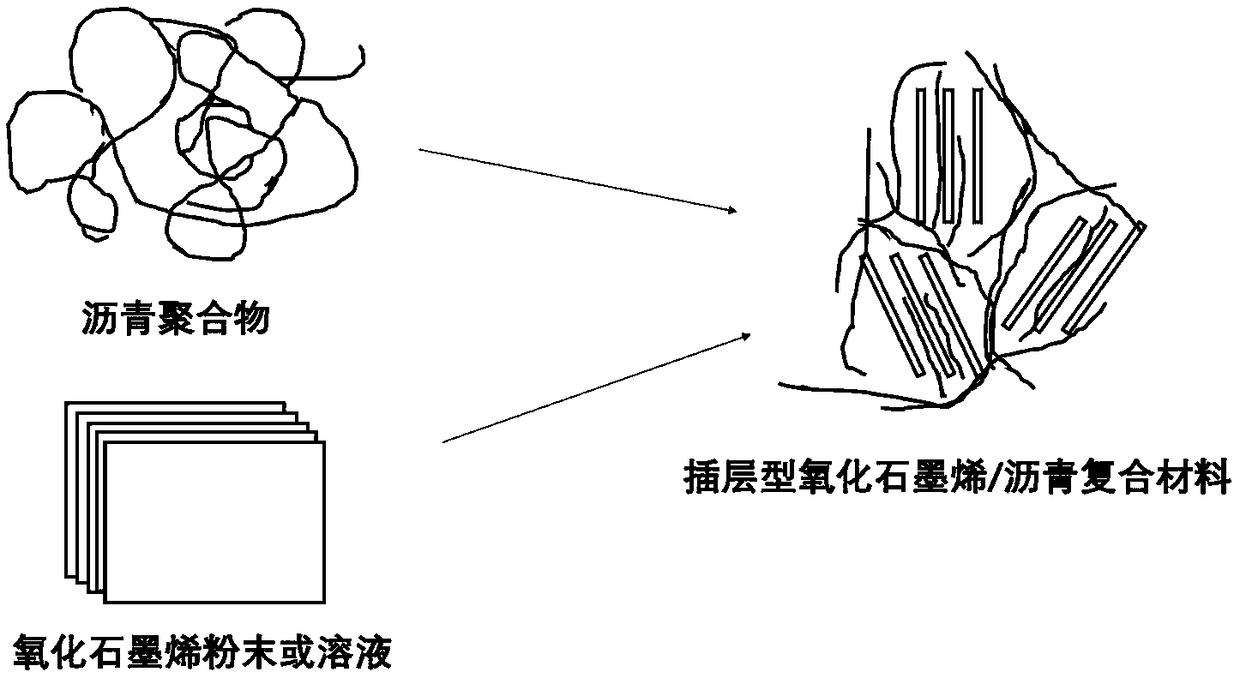

Oxidized graphene modified asphalt and preparation method thereof

A graphene modification, graphene technology, applied in building components, building insulation materials, buildings and other directions, can solve the problems of low elastic modulus, road cracking, easy oxidation and aging of asphalt pavement, etc., to achieve comprehensive performance improvement, road use Long life and effect of improving anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

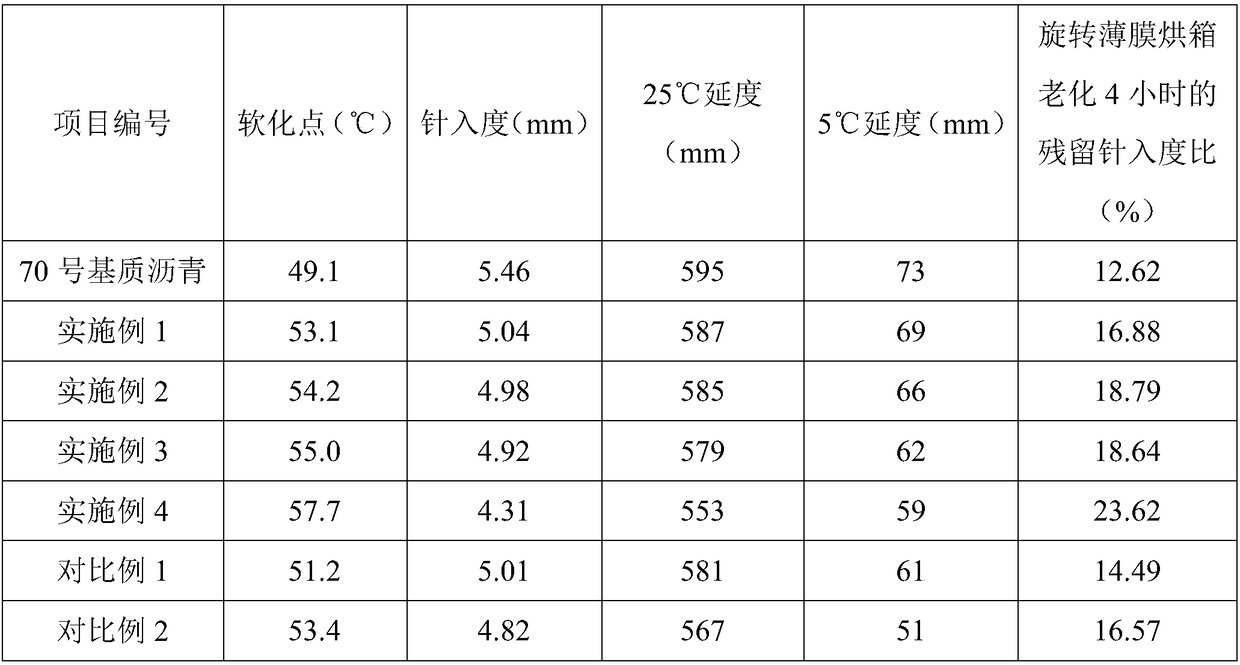

Embodiment 1

[0041] A graphene oxide modified asphalt of the present invention, the graphene oxide modified asphalt comprises the following parts by weight of raw materials: 100 parts of asphalt, 0.17 parts of graphite, 38.19 parts of mixed acid, 0.93 parts of potassium permanganate, 11.89 parts of hydrogen peroxide . Among them, graphite is natural graphite with a particle size of -160 mesh; potassium permanganate has a particle size of -100 mesh; and the mixed acid is formed by mixing 34.72 parts of concentrated sulfuric acid and 3.47 parts of concentrated phosphoric acid.

[0042] The preparation method of graphene oxide modified asphalt of this embodiment includes the following steps:

[0043] (1) Slowly add graphite to the mixed acid and stir evenly to obtain the mixed material;

[0044] (2) Place the mixture after step (1) in a heat-collecting magnetic stirrer, turn on the stirring, the stirring speed is 20rpm, the stirring temperature is 50°C, slowly add potassium permanganate to the mixt...

Embodiment 2

[0049] A graphene oxide modified asphalt of the present invention includes the following raw materials in parts by weight: 100 parts of asphalt, 0.34 parts of graphite, 76.38 parts of mixed acid, 1.86 parts of potassium permanganate, and 23.78 parts of hydrogen peroxide . Among them, the pitch used is No. 70 pitch; graphite is natural graphite with a particle size of -160 mesh; potassium permanganate has a particle size of -100 mesh; the mixed acid is made by mixing 69.44 parts of concentrated sulfuric acid and 6.94 parts of concentrated phosphoric acid.

[0050] The preparation method of graphene oxide modified asphalt of this embodiment includes the following steps:

[0051] (1) Slowly add graphite to the mixed acid and stir evenly to obtain the mixed material;

[0052] (2) Place the mixture after step (1) in a heat-collecting magnetic stirrer, turn on the stirring, the stirring speed is 20rpm, the stirring temperature is 50°C, slowly add potassium permanganate to the mixture, and...

Embodiment 3

[0057] A graphene oxide modified asphalt of the present invention includes the following raw materials in parts by weight: 100 parts of asphalt, 0.34 parts of graphite, 76.38 parts of mixed acid, 1.86 parts of potassium permanganate, and 23.78 parts of hydrogen peroxide . Among them, the pitch used is No. 70 pitch; graphite is natural graphite with a particle size of -200 mesh; the particle size of potassium permanganate is -140 mesh; the mixed acid is made by mixing 69.44 parts of concentrated sulfuric acid and 6.94 parts of concentrated phosphoric acid.

[0058] The preparation method of graphene oxide modified asphalt of this embodiment includes the following steps:

[0059] (1) Slowly add graphite to the mixed acid and stir evenly to obtain the mixed material;

[0060] (2) Put the mixture after step (1) in a heat-collecting magnetic stirrer, turn on the stirring, the stirring rate is 30rpm, the stirring temperature is 50℃, slowly add potassium permanganate to the mixture, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com