Modified compound plastic

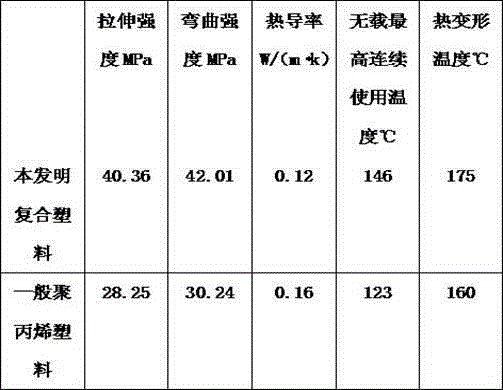

A composite plastic and modification technology, which is applied in the field of plastic production, can solve the problems of difficult to hold liquid or semi-liquid packaging, insufficient strength, poor impact resistance, etc., achieve good mechanical physical and chemical properties, improve structural quality and service life , Improve the effect of structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A modified composite plastic, in parts by weight, made of the following ingredients: 80 parts of polypropylene, 20 parts of thermoplastic styrene-butadiene rubber, 10 parts of attapulgite, 11 parts of silicon powder, 20 parts of phenolic resin, 5 parts of bentonite, acrylic acid 5 parts of sodium, 6 parts of aluminum nitride, 1 part of dispersant, 0.5 part of plasticizer, 0.2 part of heat stabilizer.

[0015] Further, the attapulgite is modified: dissolve stearic acid in kerosene to a concentration of 5.5%, then add the dried attapulgite, and after grinding for 2 hours, treat it at 100°C for 30 minutes at a constant temperature , Cool to room temperature, filter and dry.

[0016] Further, the silicon powder is mixed with a 4.5% phosphoric acid solution, treated at a constant temperature of 80-95° C. for 1-1.5 hours, filtered, and dried.

[0017] Further, the dispersant is sodium hexametaphosphate, the plasticizer is citrate, and the heat stabilizer is dibasic lead phosphite. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com