Hydrophobically modified acrylate emulsion and preparation method thereof

An acrylate and hydrophobic modification technology, applied in the direction of coating, etc., can solve the problems of low crosslinking density of the copolymer and the performance of the coating film cannot reach the optimal effect, etc. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a method for preparing a hydrophobically modified acrylate emulsion, the method comprising:

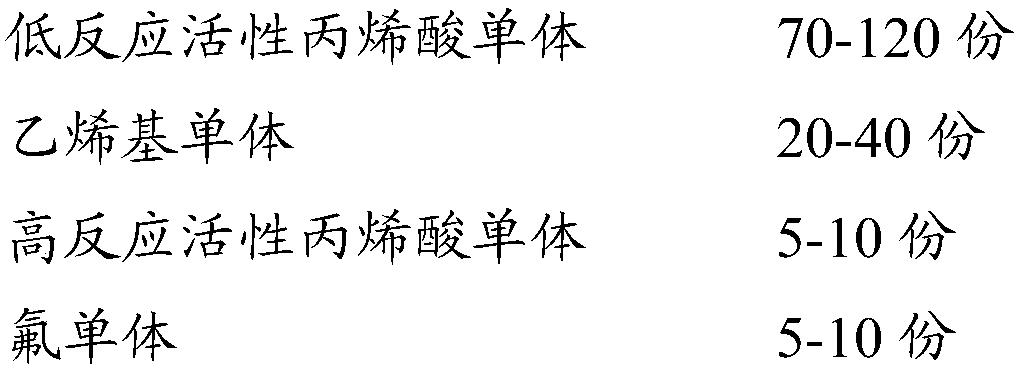

[0030] Prepare the following raw materials in parts by weight:

[0031] .

[0032] The first pre-emulsion preparation step: take 25%-40% of the low-reactivity acrylic monomer, 50%-80% of the vinyl monomer, 30%-40% of the emulsifier, and 25% of the raw material -40% of the initiator is added to 25%-40% of the distilled water in the raw material, and after high-speed stirring, the first pre-emulsion is obtained.

[0033] Specifically, when the step of preparing the first pre-emulsion is carried out in a beaker or a flask, the rotation speed of the high-speed stirring in the step of preparing the first pre-emulsion may be 800-1000 r / min.

[0034] The second pre-emulsion preparation step: take the remaining low-reactivity acrylic monomer, the remaining vinyl monomer, the remaining emulsifier, the high-reactivity acrylic monomer, ...

Embodiment 1

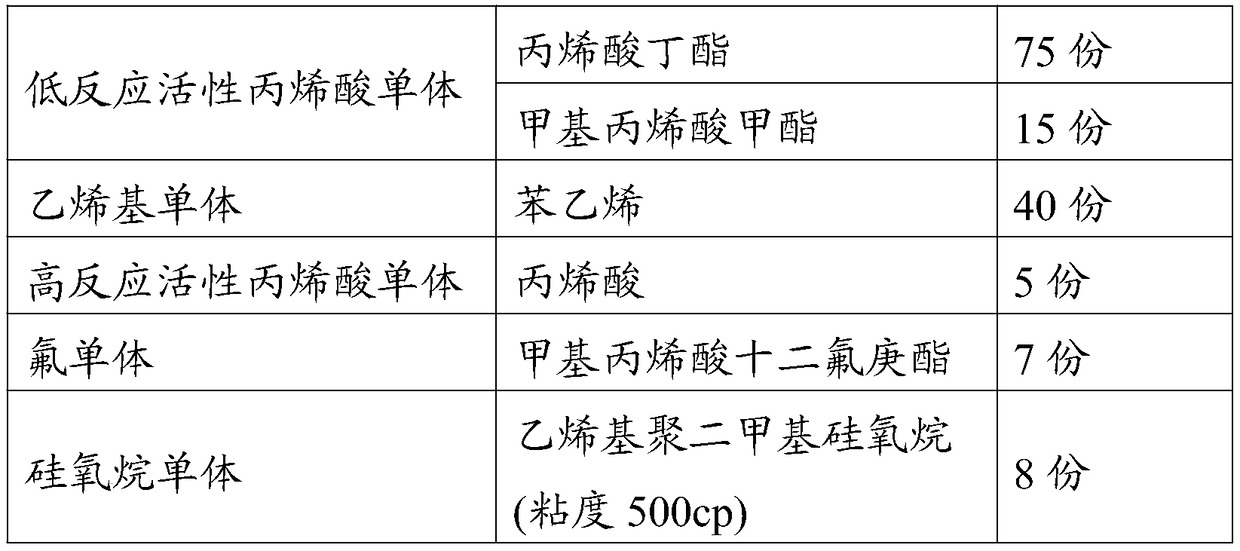

[0065] Prepare the following raw materials in parts by weight:

[0066]

[0067]

[0068] Preparation steps of the first pre-emulsion: Take 25 parts of butyl acrylate, 9 parts of methyl methacrylate, 25 parts of styrene, 3 parts of SR-10, 0.3 part of ammonium persulfate, add 60 parts of distilled water, at 800r / min Stirring for 40min at a rotating speed of 1.0 to obtain the first pre-emulsified emulsion.

[0069] The second pre-emulsion preparation step: take the remaining 50 parts of butyl acrylate, 6 parts of methyl methacrylate, 15 parts of styrene, 5 parts of SR-10, 5 parts of acrylic acid, 7 parts of dodecafluoromethacrylate in the raw materials Heptyl ester, 8 parts of vinyl polydimethylsiloxane (viscosity 500cp), were added to 115 parts of distilled water, and stirred at a speed of 1200r / min for 40min to obtain the second pre-emulsion;

[0070] Initiator solution preparation steps: take the remaining 0.6 parts of ammonium persulfate in the raw material, add 5 par...

Embodiment 2

[0076] Prepare the following raw materials in parts by weight:

[0077]

[0078]

[0079] The first pre-emulsion preparation steps: take 15 parts of butyl acrylate, 9 parts of methyl methacrylate, 17 parts of styrene, 2 parts of sodium lauryl sulfate, 2 parts of nonylphenol polyoxyethylene ether, 0.3 parts of Add ammonium sulfate to 60 parts of distilled water, and stir for 30 minutes at a speed of 1000 r / min to obtain the first pre-emulsified emulsion.

[0080] The second pre-emulsion preparation step: take the remaining 75 parts of butyl acrylate, 3 parts of methyl methacrylate, 5 parts of styrene, 4 parts of sodium lauryl sulfate, and 4 parts of nonylphenol polyoxyethylene ether in the raw materials , 8 parts of acrylic acid, 10 parts of dodecafluoroheptyl methacrylate, 8 parts of vinyl polydimethylsiloxane (viscosity 800cp), add 145 parts of distilled water, and stir for 40min at a speed of 1200r / min to obtain the first Two pre-emulsions;

[0081] Initiator solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com