High-efficiency coil type heat exchange evaporator and heat exchange method

A tubular heat exchange and evaporator technology, which is used in evaporators/condensers, lighting and heating equipment, refrigeration components, etc. and other problems, to achieve the effect of improving steam quality, less consumables, and small gaseous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

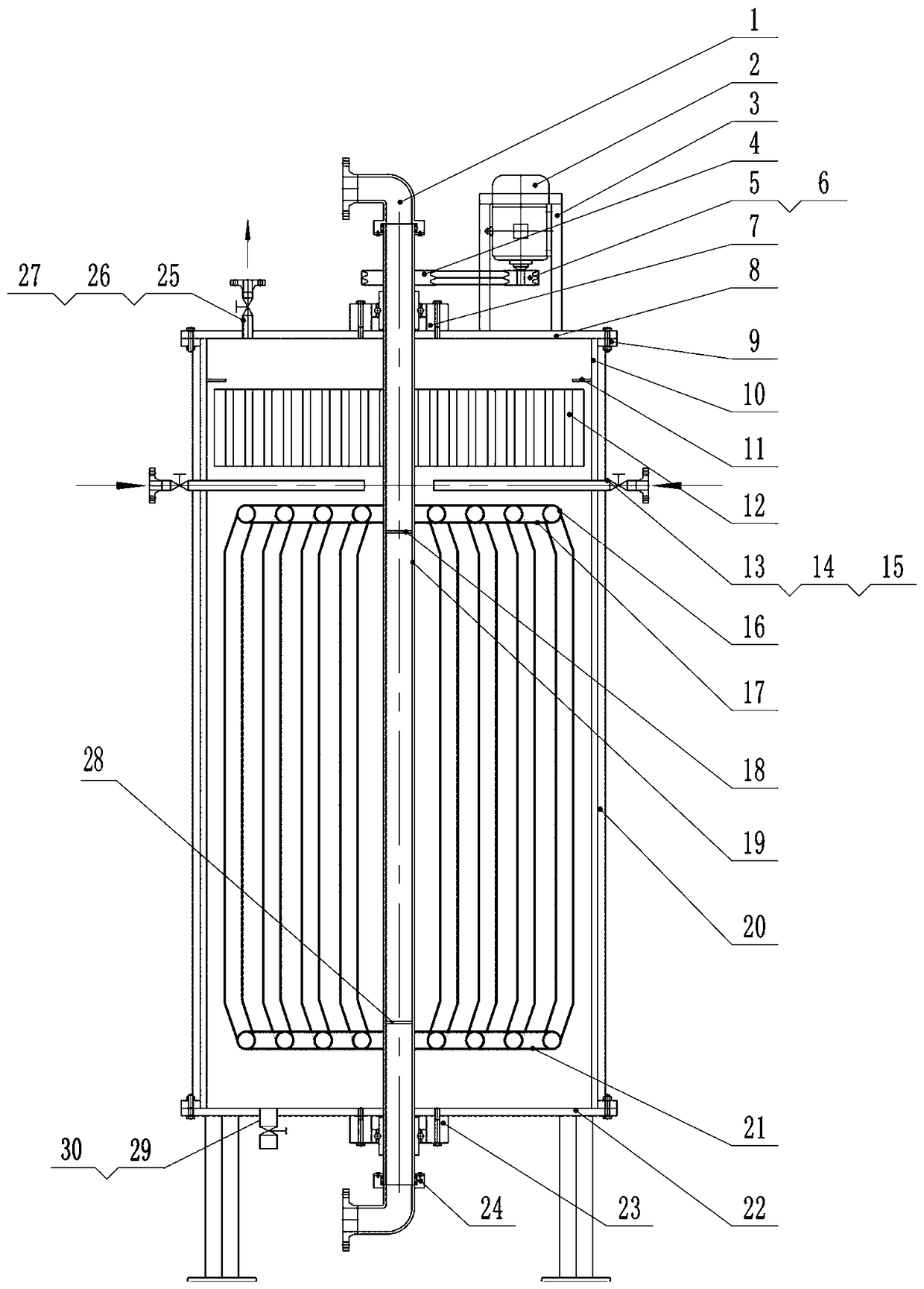

[0039] Embodiment one, such as figure 1As shown, including a hollow cylinder (10), a tubular rotating shaft (19) is installed in the center of the cylindrical body (10), and the upper and lower ports of the tubular rotating shaft (19) respectively pass through the upper rotary joint (1), the lower The swivel joint (24) is connected with the external fixed water pipe, and the tubular rotating shaft (19) is respectively fixed on the upper cover plate (8) and the lower cover plate outside the cylinder (10) through the upper end bearing (7) and the lower end bearing (23) (22), the upper cover plate (8) and the lower cover plate (22) are sealed and connected to the cylinder body (10) through the cover plate flange (9), and the upper cover plate (8) is equipped with frequency conversion adjustable speed Drive device, variable frequency drive device is composed of variable frequency motor (2), motor bracket (3), motor pulley (5), shaft pulley (4) and V-belt (6), motor bracket (3) is ...

Embodiment 2

[0050] Embodiment 2, according to the diameter of the cylindrical body (10), a plurality of evenly arranged rotary tube devices can be arranged radially around the tubular rotating shaft (19), that is, with the tubular rotating shaft (19) as the center of the circle, radially set There are multiple layers of small-diameter tubes (16) arranged in concentric circles to form a group of small-diameter tubes arranged in a multi-layer ring. The upper end of each small-diameter tube (16) is firmly fixed on the upper end of the tubular shaft (19). On the last annular pipe (17), the lower end of every screw small-diameter pipe (16) is firmly fixed on the lower annular pipe (21) communicated with the lower end of the tubular rotating shaft (19).

[0051] Because it is a multi-layer small-diameter tube group composed of multiple small-diameter tubes connected in parallel, the liquid resistance in the small-diameter tube is very small, the volume of the cylinder outside the small-diameter ...

Embodiment 3

[0052] Embodiment 3, the blade on the impeller bracket can also be set as an integral blade, and there are a plurality of louver-shaped air grooves in the vertical direction on the blade, and the louvers of the adjacent louver-shaped air grooves are opened in opposite directions, so that through the louver The airflow turbulence of the air groove is stronger.

[0053] Materials such as containers, spiral tubes, and rotating vane plates are designed according to the needs of heat exchange liquids and evaporating liquids. Materials such as copper, stainless steel, iron, and aluminum can be used. The size of the container, diameter, length, and number of tubes are determined according to the energy conversion power. Sure.

[0054] The evaporating surface area of the evaporating liquid in the present invention is very large, and the rotating liquid pipe ensures that a very stable liquid film is formed on the outer surface of the coiled pipe. In addition, the wind speed formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com