Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

A technology of nanofluids and graphene nanosheets, applied in the direction of nanocarbons, heat exchange materials, chemical instruments and methods, etc., can solve the problem of low heat conduction and heat transfer performance of nanofluids, difficult heat transfer and heat exchange of nanofluids Problems such as working fluid and difficulty in large-scale industrial production, etc., to achieve the effects of large-scale production, wide source of materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

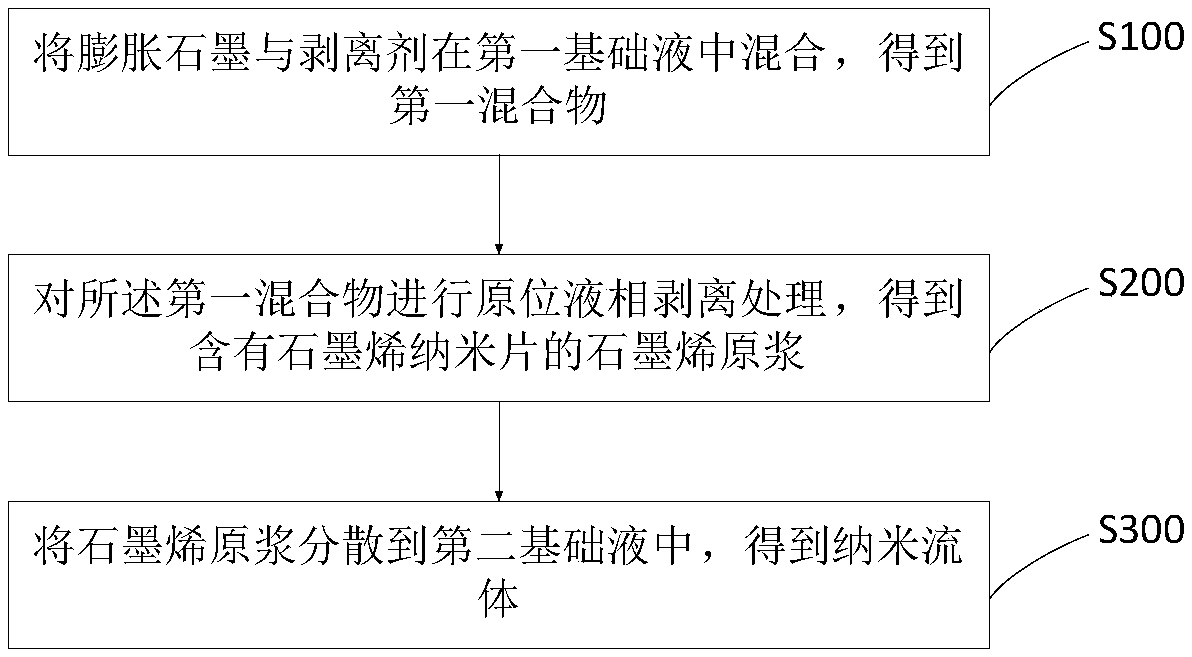

Method used

Image

Examples

Embodiment 1

[0057] Preparation method of nanofluid:

[0058] (1) With expanded graphite (fixed carbon content is 98%, particle diameter is 100 microns) as raw material, add water and polyethylene glycol p-isooctyl phenyl ether successively, the mass ratio of the three is 1:3.8:0.2, Stir and mix evenly at room temperature, mix and disperse in a high-pressure homogenizer for 30 minutes, and then grind and peel for 2 hours through a pin-type sand mill. (i.e. the mixture of expanded graphite, water and polyethylene glycol to isooctyl phenyl ether) is 15kWh / kg, obtains the graphene puree containing 20wt% graphene nanosheet;

[0059] (2) The specific surface area and pore volume of the graphene nanosheets in the graphene protoplasm were tested by BET method (using the model ASAP2460, the specific surface tester of Micromeritics), which reached 2711m3 respectively. 2 / g and 1.276cm 3 / g (eg image 3 shown);

[0060] (3) The chemical structure of graphene nanosheets in the graphene protoplasm...

Embodiment 2

[0066] Preparation method of nanofluid:

[0067] (1) With expanded graphite (fixed carbon content is 95%, particle size is 5 microns) as raw material, add water and sodium dodecylbenzenesulfonate successively, the mass ratio of the three is 1:8.8:0.2, at room temperature Stir and mix evenly, mix and disperse in a high-pressure homogenizer for 30 minutes, and then grind and peel off for 2 hours through a pin-type sand mill. The ratio of graphite, water and polyethylene glycol to the mixture of isooctyl phenyl ether) is 2kWh / kg, obtains the graphene puree containing 10wt% graphene nanosheet;

[0068] (2) add water to the graphene protoplasm and dilute the concentration of graphene nanosheets to 0.05wt%, homogenize by a high-speed shear emulsifier for 30 minutes, the energy consumed by high-speed shear emulsification and the quality of the processed material (i.e. the original graphene The ratio of slurry and water) is 0.1kWh / kg to obtain a uniformly dispersed nanofluid, wherein...

Embodiment 3

[0071] Preparation method of nanofluid:

[0072] (1) Take expanded graphite (fixed carbon content of 99.9%, particle size of 1000 microns) as raw material, add water and sodium lauryl sulfate in turn, the mass ratio of the three is 4:5.8:0.2, stir and mix at room temperature Evenly, mix and disperse in a high-pressure homogenizer for 30 minutes, and then grind and peel off for 2 hours through a pin-type sand mill. The ratio of water and polyethylene glycol to the mixture of isooctyl phenyl ether) is 100kWh / kg, obtains the graphene puree containing 40wt% graphene nanosheet;

[0073] (2) add water to the graphene protoplasm and dilute the concentration of graphene nanosheets to 0.1wt%, homogenize by high-speed shear emulsification machine for 30 minutes, the energy consumed by high-speed shear emulsification and the quality of the processed material (i.e. the original graphene The ratio of slurry and water) is 0.1kWh / kg to obtain a uniformly dispersed nanofluid, wherein the max...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com