Silicon-based cavity shielding filter

A filter and cavity technology, applied in the field of silicon-based micro-shielded MEMS filters, can solve the problems of large loss of microwave filter structure, inability to perform high-density integration, and heavy metal cavity weight, and achieve small size and high quality. Factors, good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention will be described below in conjunction with the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

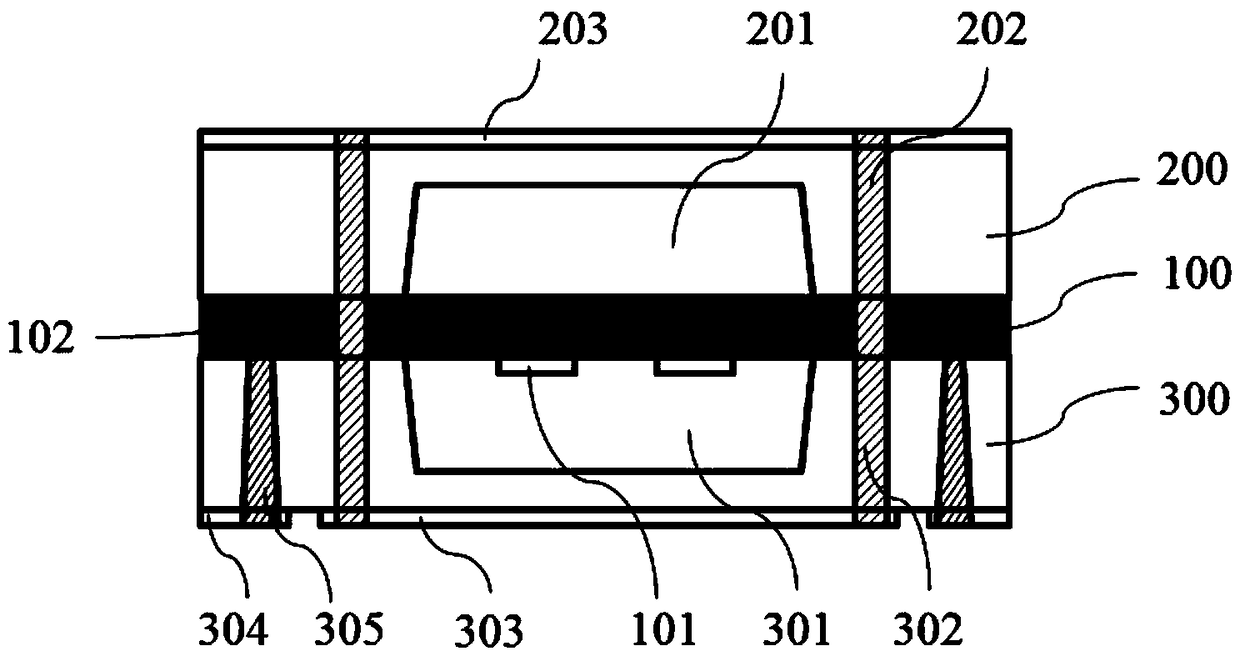

[0033] Such as Figure 1-Figure 4 As shown, the silicon-based cavity shielding filter of this embodiment is made by MEMS technology; it includes a first substrate 200, a second substrate 300, an intermediate layer 100 and a metal suspension circuit 101. The first The substrate 200 and the second substrate 300 are respectively high-resistance silicon substrates. The first substrate 200, the intermediate layer 100, and the second substrate 300 are sequentially stacked and combined into a silicon cavity structure; on the intermediate layer 100 A microwave ground electrode 103 is provided, and a metal shielding layer connected to the microwave ground electrode 103 is provided on the outer surface of the silicon cavity structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com