Summer quilt formed through spinning and production method of summer quilt

A production method and technology of cool quilts, which are applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of threats to human health, poor warmth retention, poor air permeability, and poor cohesion, and achieve periodic and durable, comfortable home feeling , to achieve the effect of pursuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

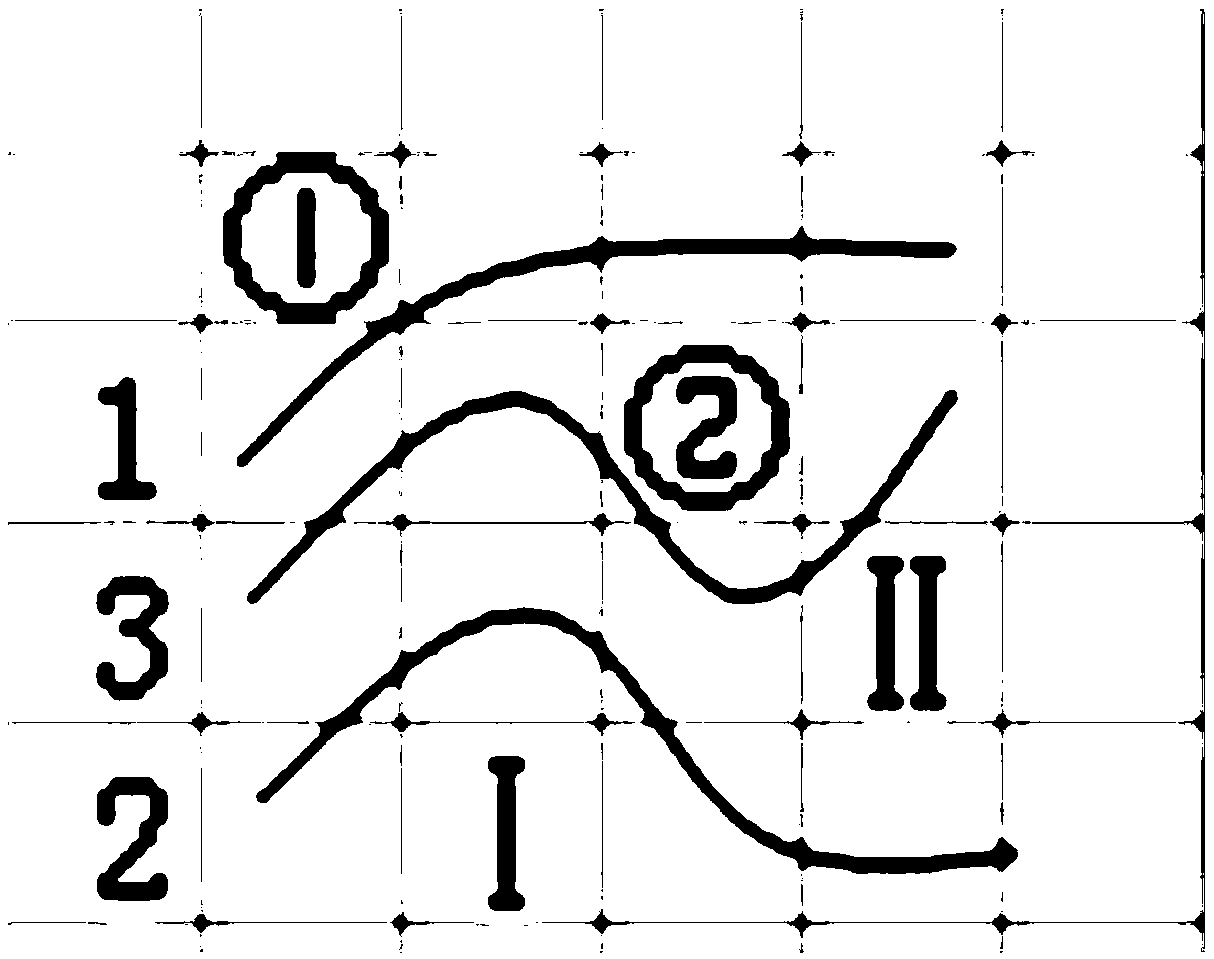

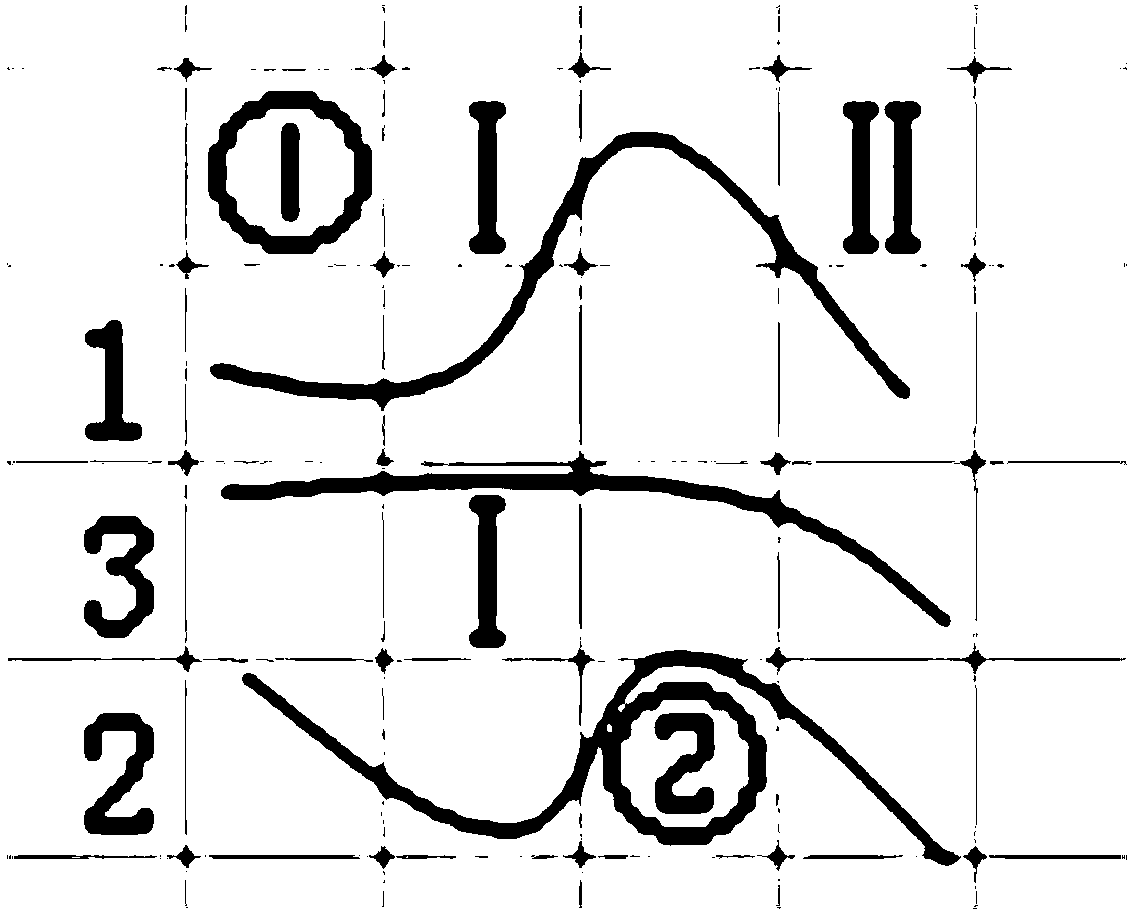

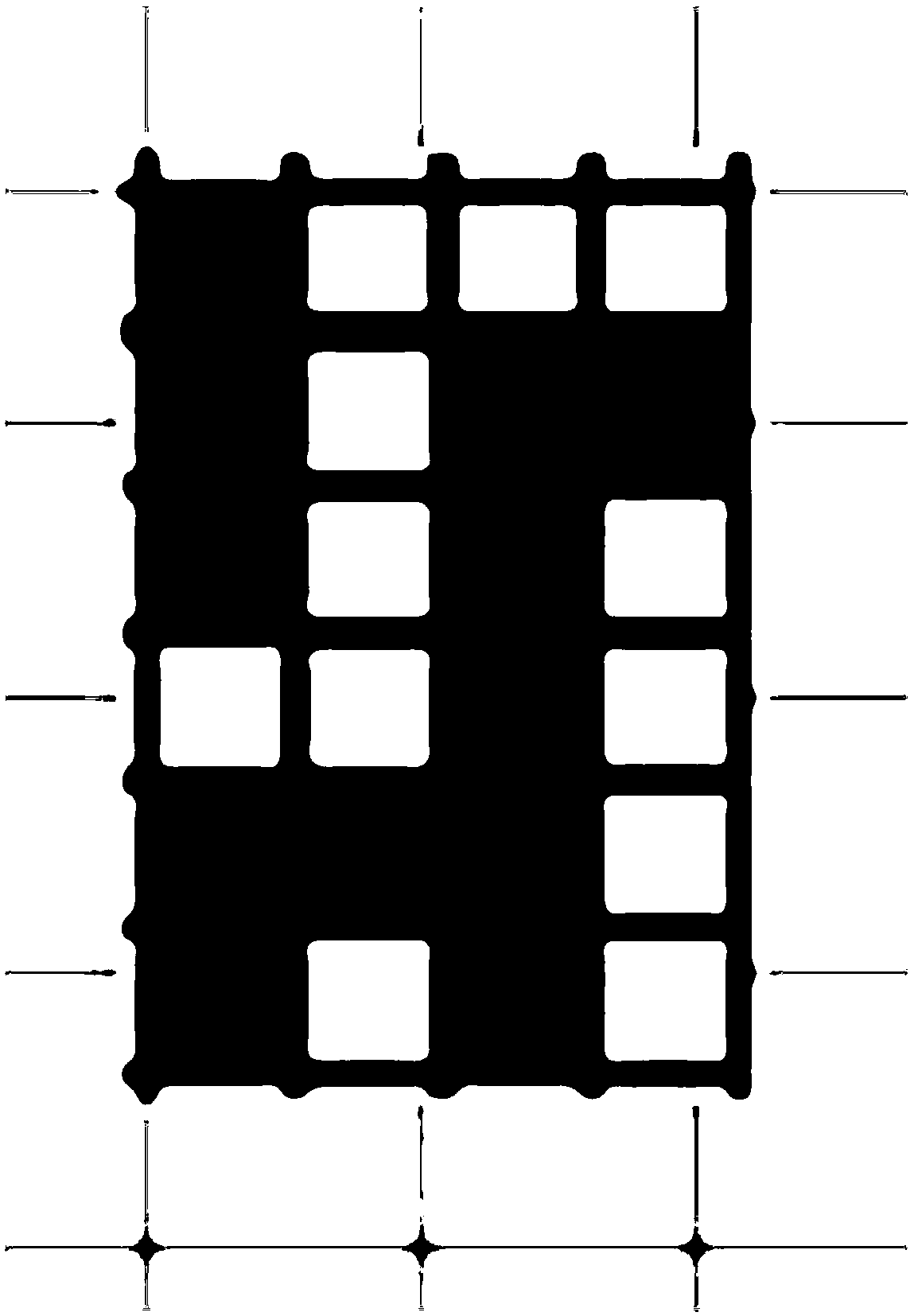

Method used

Image

Examples

Embodiment 1

[0031] 1) Spinning: In the spinning process, the tencel and water-soluble filaments are spun into untwisted yarn by combining spun yarn and two-for-one twisting, and the yarn strength is 600 CN;

[0032] 2) Weaving: Viscose dyed yarn and warp yarn interweave to form the surface layer, the warp yarn density is 340 / 10cm, the middle is a filling layer composed of polyester filament as raw material; 10cm; after interlacing, the weft yarn density range of the surface layer is 170 / 10cm, the weft yarn density range of the middle layer is 170 / 10cm, the weft yarn density range of the bottom layer is 170 / 10cm, the weaving tension is 3250N, the warp breaking strength is 645 N, and the weft breaking strength is 1335 N; Set the loom speed at 467r / min;

[0033] 3) Water treatment and dyeing treatment: firstly, at 97°C for 25 minutes to remove the water-soluble silk in the untwisted yarn, and then bleach and dye with 10g / L NaOH solution and 2g / L alkali weight reduction accelerator , and fin...

Embodiment 2

[0035] 1) Spinning: In the spinning process, tencel and water-soluble filaments are spun into untwisted yarn by combining spun yarn and two-for-one twisting, and the yarn strength reaches 580 CN;

[0036]2) Weaving: Viscose dyed yarn and warp yarn interweave to form the surface layer, the warp yarn density is 330 / 10cm, and the filling layer is made of polyester filament as raw material in the middle; 10cm; after interlacing, the weft yarn density range of the surface layer is 167 / 10cm, the weft yarn density range of the middle layer is 167 / 10cm, the weft yarn density range of the bottom layer is 167 / 10cm, the weaving tension is 3250N, the warp breaking strength is 630 N, and the weft breaking strength is 1320 N; Set the loom speed at 450r / min;

[0037] 3) Water treatment and dyeing treatment: firstly, at 95°C for 30 minutes to remove the water-soluble silk in the untwisted yarn, and then bleach and dye with 5g / L NaOH solution and 1g / L alkali weight reduction accelerator , a...

Embodiment 3

[0039] 1) Spinning: In the spinning process, the tencel and water-soluble filaments are spun into untwisted yarn by combining spun yarn and two-for-one twisting, and the yarn strength reaches 500 CN;

[0040] 2) Weaving: Viscose dyed yarn and warp yarn interweave to form the surface layer, the warp yarn density is 345 / 10cm, and the filling layer is made of polyester filament in the middle; 10cm; after interlacing, the weft yarn density range of the surface layer is 173 / 10cm, the weft yarn density range of the middle layer is 173 / 10cm, the weft yarn density range of the bottom layer is 173 / 10cm, the weaving tension is 3250N, the warp breaking strength is 660 N, and the weft breaking strength is 1350 N; Set the loom speed at 500r / min;

[0041] 3) Water treatment and dyeing treatment: firstly treat the water-soluble silk in the untwisted yarn at 95℃~98℃ for 20min~30min, and then use 5g / L~15g / L NaOH solution with a concentration of 1g / L~ 4g / L alkali weight reduction accelerator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com