Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal aligning agent and substituent technology, which is applied in liquid crystal materials, instruments, optics, etc., can solve the problems of incomplete restoration of liquid crystal to the initial state, light leakage contrast of liquid crystal display elements, unqualified surface display of alignment films, etc., to reduce electrostatic dust. The effect of attracting characters, reducing the electrostatic breakdown of the film surface and improving the uniformity of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

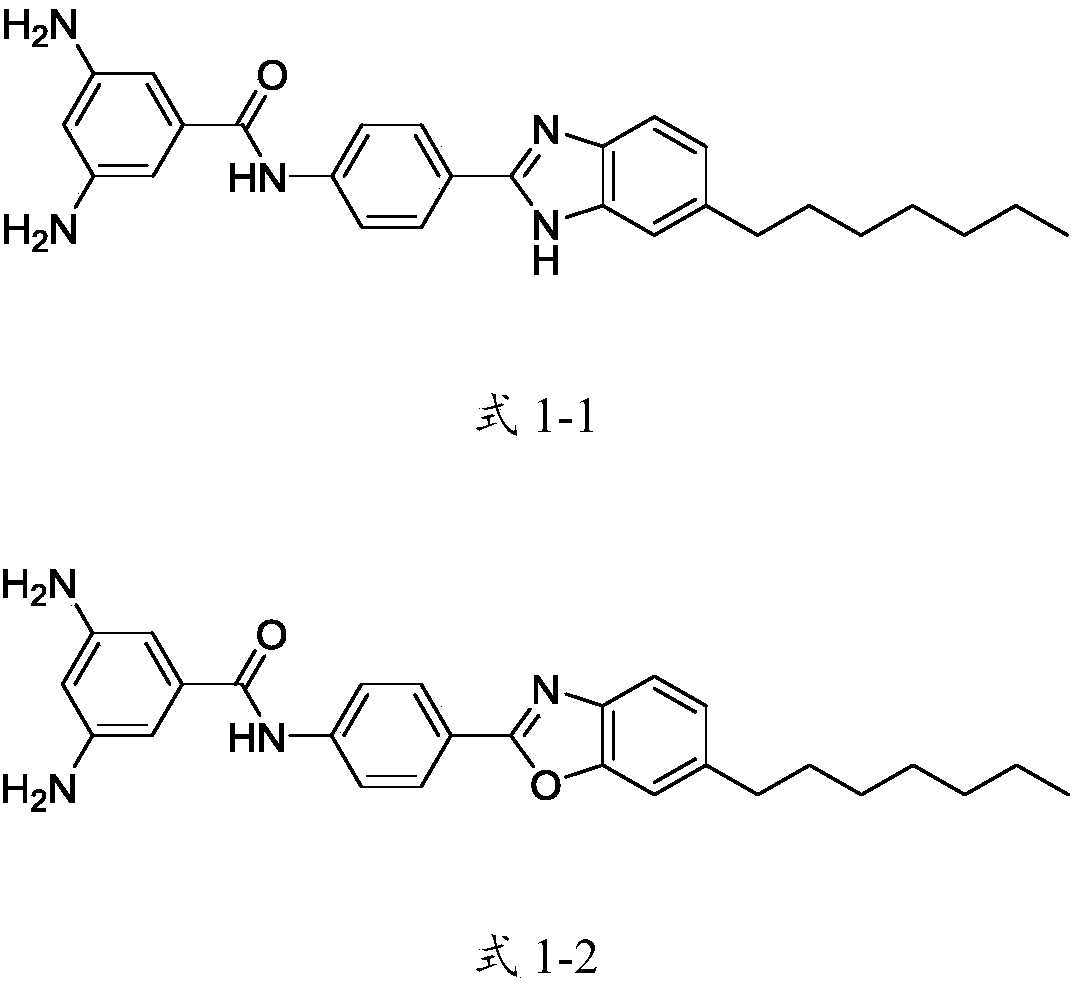

[0048] The synthesis of the diamine compound represented by structural formula 1-1 is shown in Synthetic Route 1:

[0049]

[0050] Synthetic route 1

[0051] The specific operation process is:

[0052] (1) Synthesis of compound 1-1-a

[0053] Put p-4-n-heptyl-2-aminoaniline (41.27g, 200mmol), triethylamine (24.29, 240mmol) and 300ml of DMAC solvent into a 1000mL three-neck round bottom flask, cool to 0-10°C Start to drop the mixed solution of p-nitrobenzoyl chloride (37.11g, 200 mmoles) and 200ml solvent DMAC in the system, after 0.5 hours the dropwise addition is completed, heat up to 60°C and keep it warm for 10 hours, then pour the reaction solution into ice In water, the precipitate was filtered out, washed with water, and the filter cake was crystallized from a mixture of dioxane / water (2:1) to obtain a light yellow solid 1-1-a. The product was tested by high-resolution mass spectrometry, M / Z=355.17 , confirmed as the target product 1-1-a.

[0054] (2) Synthesis o...

Embodiment 2~3

[0064] The compounds represented by structural formulas (1-2)-(1-3) can be synthesized according to the corresponding compound 4-n-heptyl-2-hydroxyaniline and 4-n-heptyl-2-mercaptoaniline respectively Route 1 was synthesized, and the high-resolution mass spectrometry results and elemental analysis results of the corresponding compounds are shown in Table 1 below.

[0065] Mass spectrum, elemental analysis data of each compound in Table 1 embodiment 2~3

[0066]

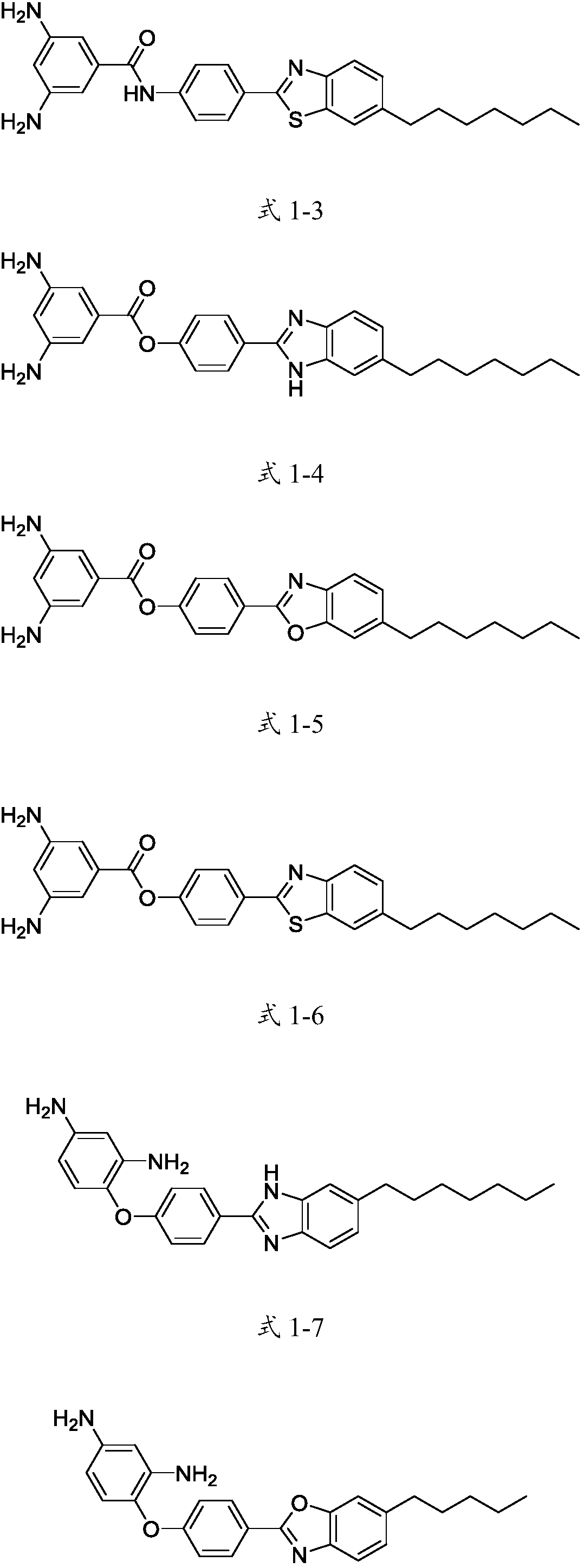

Embodiment 4

[0068] The synthetic method of the compound represented by structural formula (1-4) is basically the same as that of Synthetic Example 1, except that p-nitrobenzoyl chloride is replaced by 4-benzyloxybenzoyl chloride, and the hydrocarbon group is protected by benzyloxy , and then carry out deprotection by the method of catalytic hydrogenation, and the specific operation method can be synthesized according to the following synthetic route 2:

[0069]

[0070] Synthetic route 2

[0071] The specific operation process is as follows:

[0072] (1) Synthesis of compound 1-4-a

[0073] Drop into p-4-n-heptyl-2-aminoaniline (41.27g, 200 mmol), triethylamine (24.29 g, 240 mmol) and 300 ml of DMAC solvent in a three-neck round bottom flask of 1000 mL, cool to 0-10 ℃ began to drop the mixed solution of 4-benzyloxybenzoyl chloride (49.34g, 200 mmol) and 200ml solvent DMAC in the system, after 0.5 hours, the dropwise addition was completed, and the temperature was raised to 60 ℃ for i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pretilt | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com