Transparent photosensitive resin material for 3D printing as well as preparation method and application thereof

A 3D printing, photosensitive resin technology, used in medical science, fractures, etc., can solve the problems of opacity, low notched impact strength, residual toxic substances, etc., and achieve the effect of flexible texture, good flexibility resistance, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

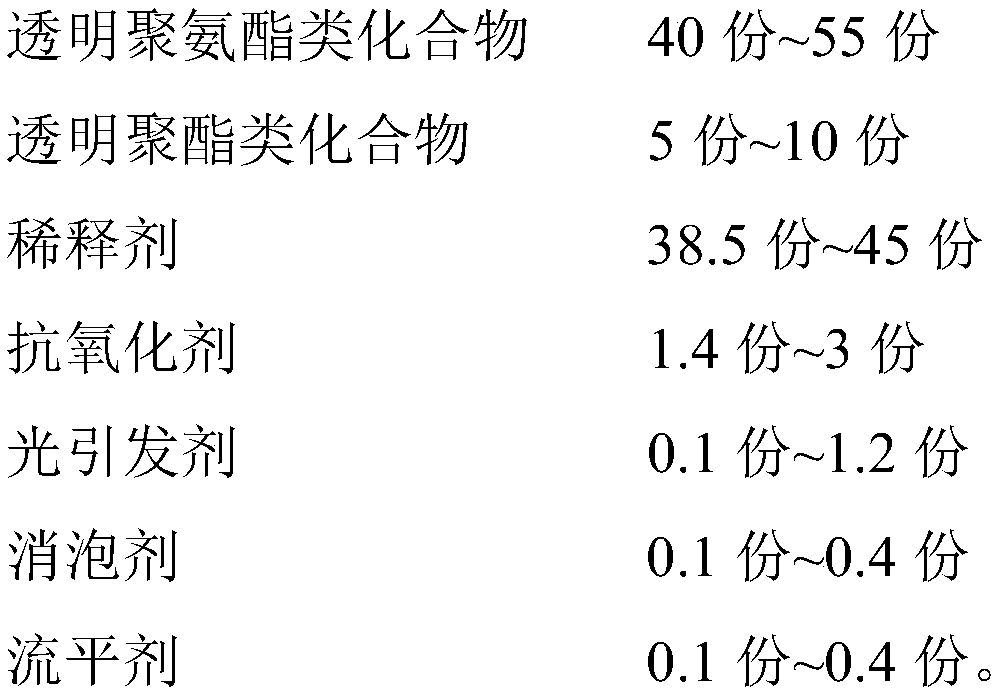

Method used

Image

Examples

Embodiment 1

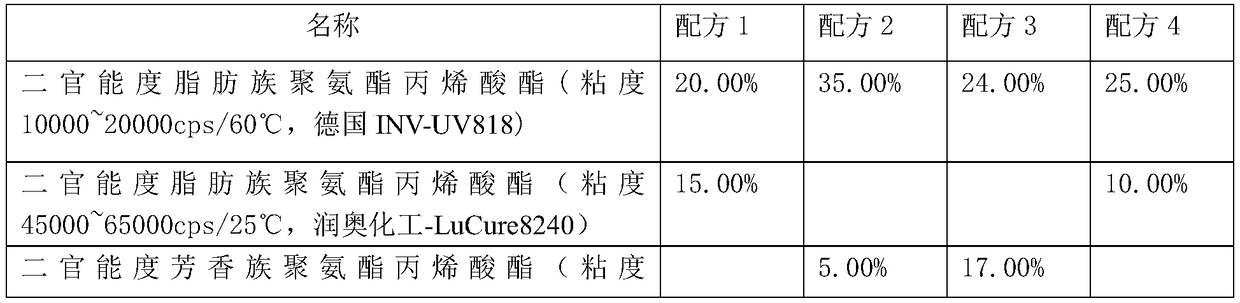

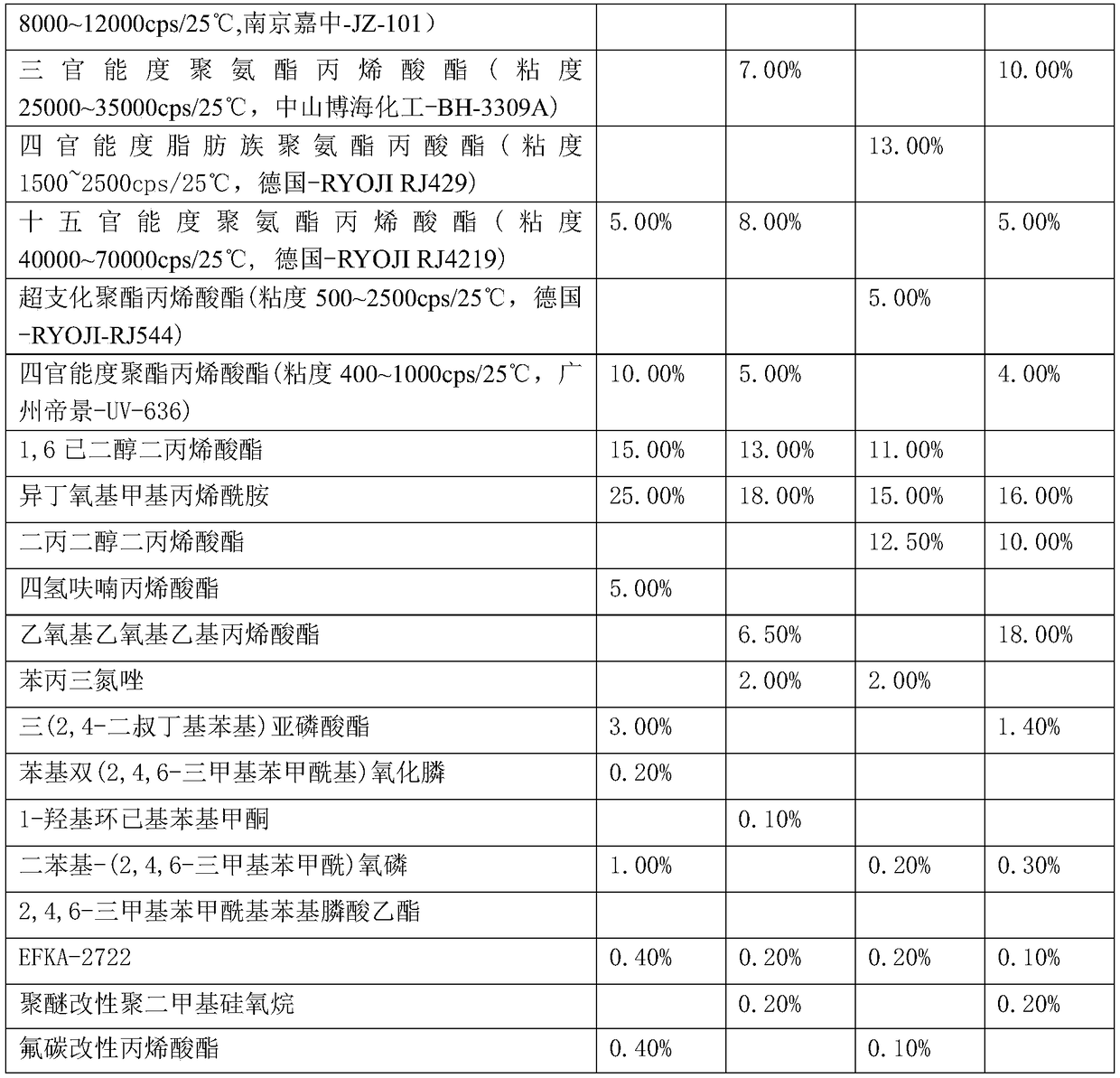

[0032] According to formula 1, formula 2, formula 3 and formula 4 shown in Table 1 below, transparent photosensitive resin materials for 3D printing are prepared, and the preparation method is as follows: add transparent polyurethane compounds, transparent polyester compounds and antioxidants into the tape In a stirring container, heat to 60°C, keep stirring until the system is transparent, then cool down to room temperature, add diluent, photoinitiator, leveling agent and defoamer according to the proportion, stir again until the system is transparent, and you can get 3D Transparent photosensitive resin material for printing.

[0033] This transparent photosensitive resin material for 3D printing can be printed into a highly transparent material on a DLP or SLA 3D printer equipped with a 385nm to 405nm ultraviolet light source.

[0034] Formula 1, formula 2, formula 3 and formula 4 in the embodiment 1 of table 1

[0035]

[0036]

[0037] Note: The percentages in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com