Electroless Plating Wastewater Advanced Treatment Method

An advanced treatment and electroless plating technology, which is applied in metallurgical wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of poor treatment effect, large molecular weight, high cost, etc., and increase the gas-liquid-solid contact area , The gas-liquid mass transfer efficiency increases, and the effect of improving the utilization rate of ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Several streams of running wastewater from an electroplating wastewater treatment plant in a park in Dongguan were taken for testing, including comprehensive wastewater, nickel-containing wastewater and electroless plating wastewater. Compare the treatment effects of various water after oxidation.

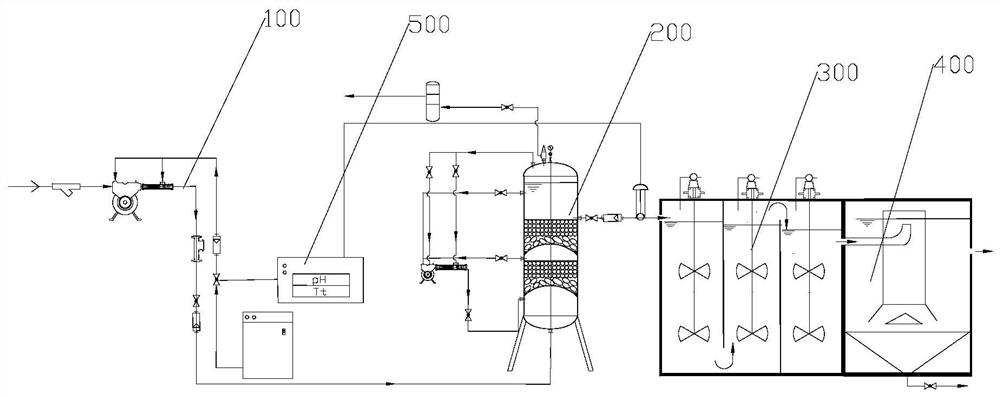

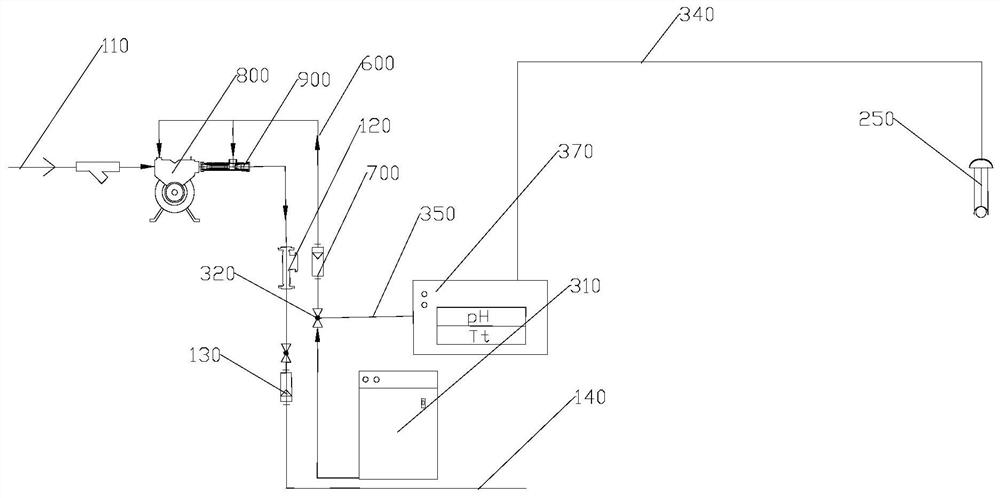

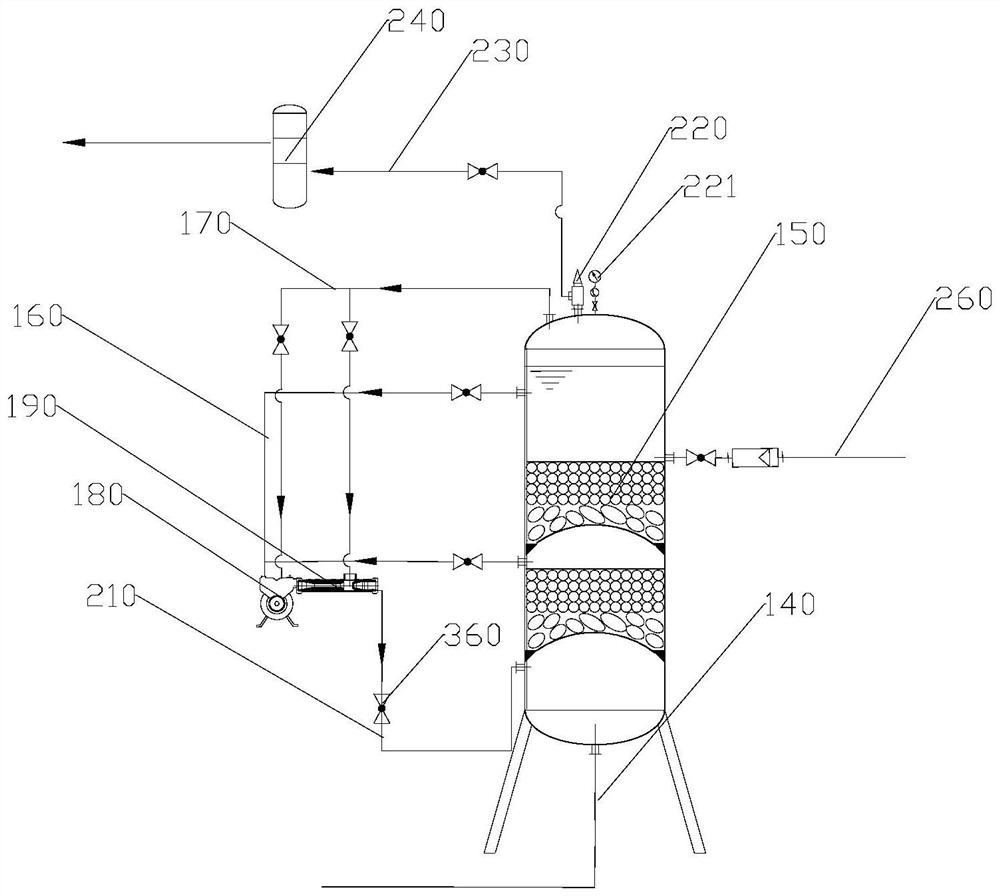

[0133] refer to Figure 1-4 , the ozone generator 310 supplies ozone to the first dissolved air pump 800 and the first ejector 900 through the ozone supply pipe 600, and a gas flow meter 700 is provided on the ozone supply pipe 600 for calculating the ozone supply amount; the waste water supply pipe 110 The waste water is supplied to the first dissolved air pump 800, and the first dissolved air pump 800 mixes the waste water with ozone and transports it to the first injector 900. After the first injector 900 mixes ozone again, it sprays it into the first feed pipe 140, A gas-liquid mixer 120 for remixing ozone and waste water is provided on the first feed pipe 140; after th...

Embodiment 2

[0144] A method for advanced treatment of electroless plating wastewater, the difference from Example 1 is that in this example:

[0145] The dosage of ozone is 120mg / L, the gas-liquid mixing ratio is 1:4, the working pressure of the catalytic ozonation reactor is 0.4Mpa, the number of catalyst layers is 2 layers, and the bulk density of the spherical solid catalyst is 1.6kg / L. 50%. The added heavy metal collector is 100mg / L, the added flocculant PAM is 150mg / L, and the added coagulant PAC is 15mg / L.

[0146] The water quality before and after the treatment in this embodiment was tested, and the test results are shown in Table 2.

[0147] Table 2 Influent water quality and effluent water quality of comprehensive wastewater, nickel-containing wastewater and electroless plating wastewater

[0148]

Embodiment 3

[0150] A kind of electroless plating waste water advanced treatment method processing technology, and the difference of embodiment 1 is, in the present embodiment:

[0151] The dosage of ozone is 150mg / L, the gas-liquid mixing ratio is 1:4, the working pressure of the catalytic ozonation reactor is 0.5Mpa, the number of catalyst layers is 2 layers, and the bulk density of the spherical solid catalyst is 1.86kg / L. 60%. The added heavy metal collector is 100mg / L, the added flocculant PAM is 180mg / L, and the added coagulant PAC is 18mg / L.

[0152] The water quality before and after the treatment in this embodiment was tested, and the test results are shown in Table 3.

[0153] Table 3 Influent water quality and effluent water quality of comprehensive wastewater, nickel-containing wastewater and electroless plating wastewater

[0154]

[0155]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com