Method for extracting and separating 5-hydroxymethylfurfural and fructose by using ionic liquid aqueous two-phase system

A technology of hydroxymethylfurfural and two-phase aqueous system, which is applied in the direction of separation methods, chemical instruments and methods, liquid solution solvent extraction, etc., can solve the problems of high separation cost, poisonous and harmful, complicated operation, etc., and achieve good chemical stability , non-volatile, large electrochemical window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 3g of [C 4 mim][CF 3 SO 3 ] solution, add 4g of NaH 2 PO 4 2H 2 O, then add 3 g of pre-prepared mixed solution of 5-hydroxymethylfurfural and 25 mg / mL fructose with a mass concentration of 1.0 mg / mL.

[0032] In order to test the accuracy of the data, each sample was equipped with three parallel experiments.

[0033] (2) After the ionic liquid two-phase aqueous system was prepared, it was shaken on a vortex shaker for 5 minutes to ensure that the whole system was evenly mixed, and then placed in a constant temperature water bath at 25°C for 1 hour. After the phase separation was completed, the upper and lower phase solutions were taken respectively for the determination of the concentrations of 5-hydroxymethylfurfural and fructose.

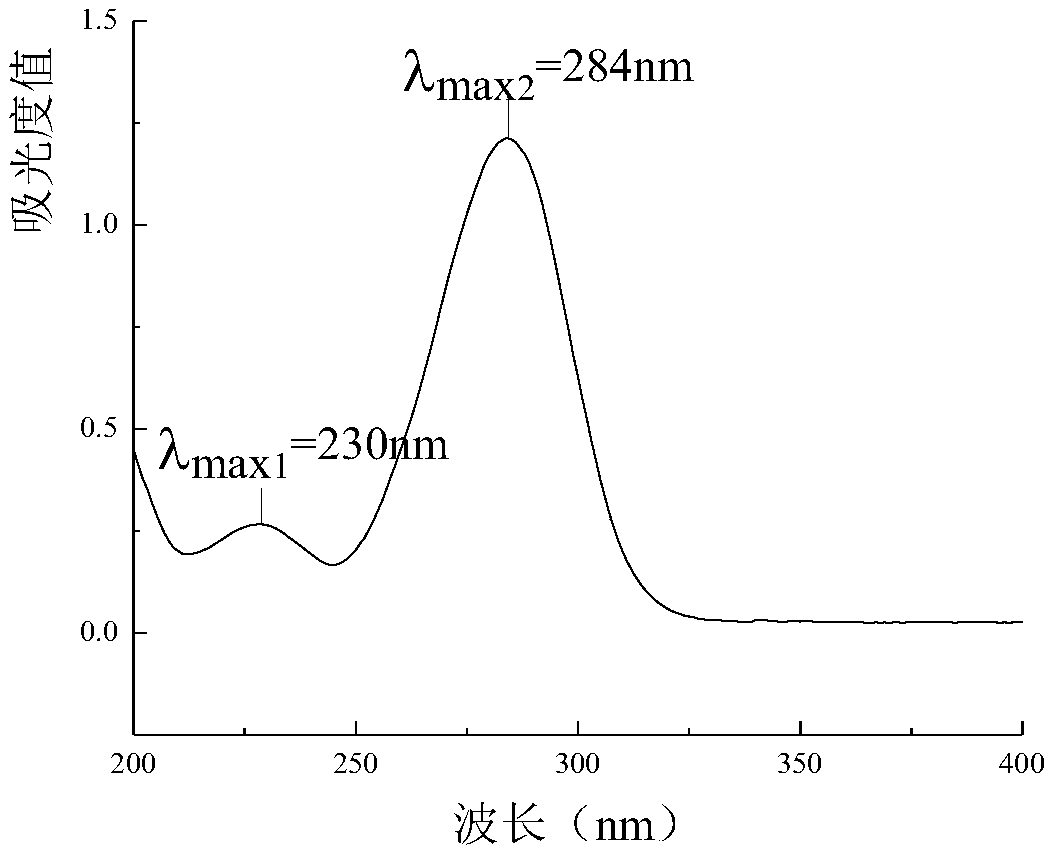

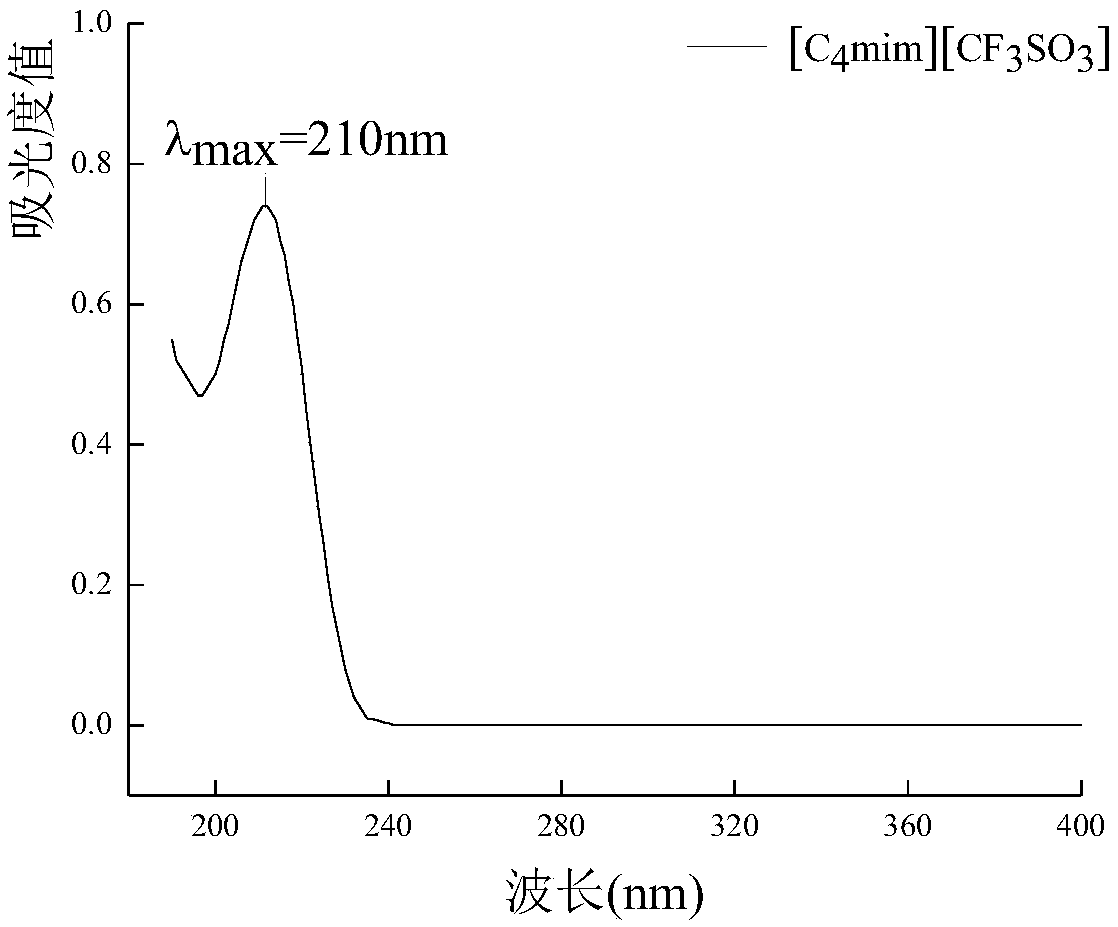

[0034] (3) in the present invention, the mensuration method of 5-hydroxymethylfurfural concentration is ultraviolet spectrophotometry, observes according to ultraviolet scanning figure, has two wave peaks, considers [C 4 mim]...

Embodiment 2

[0037] (1) Add 3g of [C 4 mim][CF 3 SO 3 ] solution, add 4g of NaH 2 PO4 2H 2 O, then add 3g of pre-prepared mass concentration of 1.5mg / mL of 5-hydroxymethylfurfural and 50mg / mL of fructose mixed solution.

[0038] In order to test the accuracy of the data, each sample was equipped with three parallel experiments.

[0039] (2) After the ionic liquid two-phase aqueous system was prepared, it was shaken on a vortex shaker for 5 minutes to ensure that the whole system was evenly mixed, and then placed in a constant temperature water bath at 25°C for 1 hour. After the phase separation was completed, the upper and lower phase solutions were taken respectively for the determination of the concentrations of 5-hydroxymethylfurfural and fructose.

[0040] (3) in the present invention, the mensuration method of 5-hydroxymethylfurfural concentration is ultraviolet spectrophotometry, observes according to ultraviolet scanning figure, has two wave peaks, considers [C 4 mim][CF 3 SO...

Embodiment 3

[0043] (1) Add 3g of [C 4 mim][CF 3 SO 3 ] solution, add 4g of NaH 2 PO 4 2H 2 O, then add 3g of pre-prepared mixed solution of 5-hydroxymethylfurfural with a mass concentration of 2.0mg / mL and 75mg / mL of fructose.

[0044] In order to test the accuracy of the data, each sample was equipped with three parallel experiments.

[0045] (2) After the ionic liquid two-phase aqueous system was prepared, it was shaken on a vortex shaker for 5 minutes to ensure that the whole system was evenly mixed, and then placed in a constant temperature water bath at 30°C for 1 hour. After the phase separation was completed, the upper and lower phase solutions were taken respectively for the determination of the concentrations of 5-hydroxymethylfurfural and fructose.

[0046] (3) in the present invention, the mensuration method of 5-hydroxymethylfurfural concentration is ultraviolet spectrophotometry, observes according to ultraviolet scanning figure, has two wave peaks, considers [C 4 mim]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com