Perovskite material, method for preparing same and solar cell device with perovskite material

A perovskite material and perovskite technology, applied in the fields of preparation, solar cell devices, and perovskite materials, can solve the problems of low efficiency and poor stability of perovskite solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the perovskite material provided by the present invention includes: providing a precursor solution of perovskite, and forming the perovskite material through the precursor solution.

[0037] In the preparation method of the perovskite material provided by the present invention, in the precursor solution, the concentration of the precursor solution is selected from 0.8M-1.4M, 0.8M-1.1M, 1.1M-1.3M, 1.3M-1.4M , preferably 1.1M-1.3M.

[0038] In the preparation method of the perovskite material provided by the present invention, the halide is added to the mixed reagent, heated and stirred to obtain the precursor solution; the halide is selected from the group consisting of dimethyl ammonium iodide, dimethyl ammonium bromide, di Methylammonium chloride, methylammonium iodide, methylammonium bromide, methylammonium chloride, formamidine hydroiodide, formamidine hydrobromide, formamidine hydrochloride, cesium iodide, bromide Cesium, cesium chloride, ...

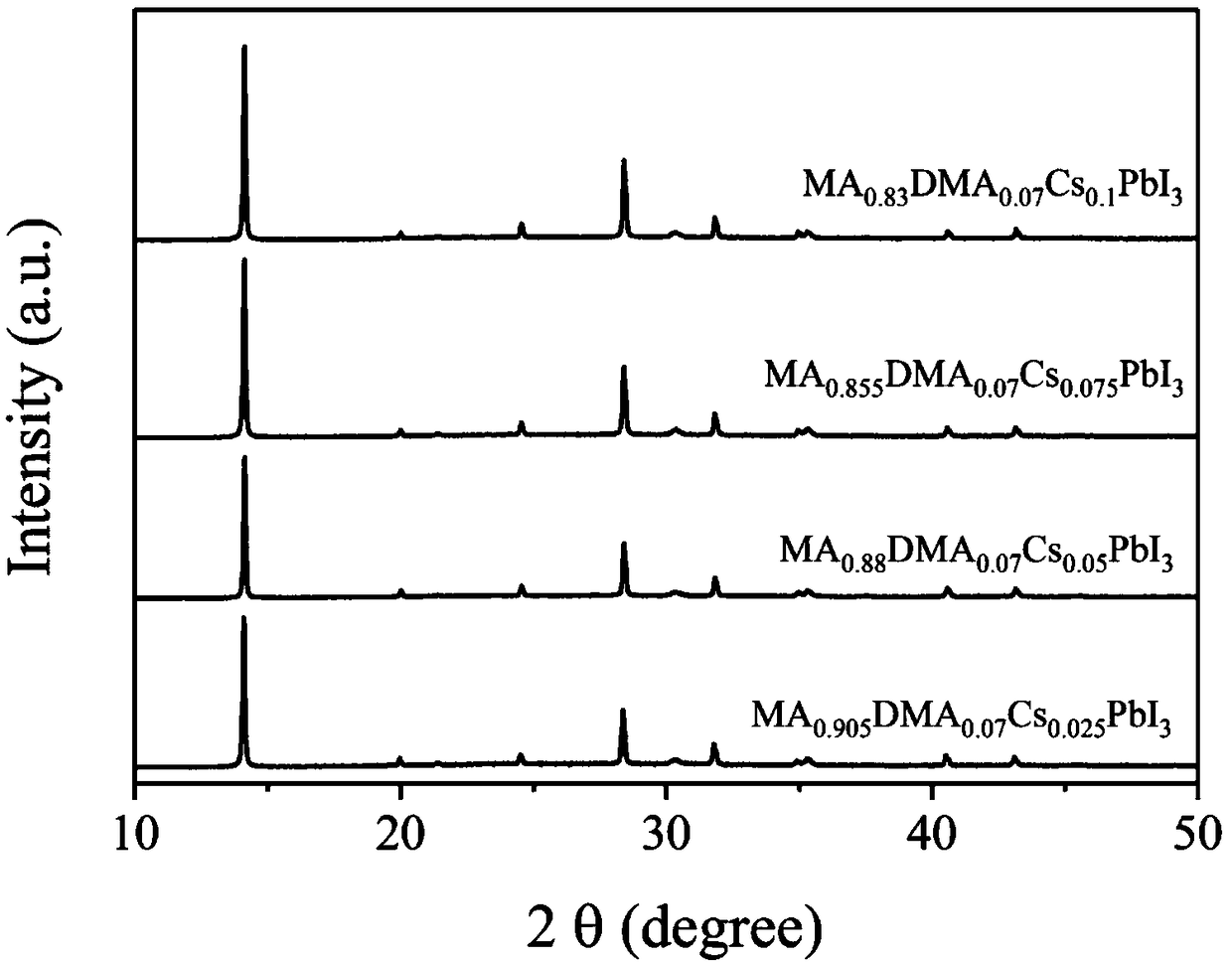

Embodiment 1

[0061] MA 0.905 DMA 0.07 Cs 0.025 PB 3 The preparation method of perovskite thin film, concrete steps are:

[0062] Take by weighing methyl ammonium iodide 0.1871g (MAI, 1.1765mmol), dimethyl ammonium iodide 0.0157g (DMAI, 0.091mmol), cesium iodide 0.0084g (CsI, 0.0325mmol) and lead iodide 0.5993g (1.3 mmol) was added to a 4ml glass bottle containing 1ml DMF and DMSO mixed reagent (volume ratio 4:1), stirred at 70°C for 1 hour, cooled, and filtered with a 0.22um polytetrafluoroethylene filter head After filtering, the resulting solution is a perovskite precursor solution. Place the nickel oxide substrate on the spin coater, drop the perovskite precursor solution on the nickel oxide substrate with a 200ul pipette gun, close the lid, and start spin coating. The spin coating parameters are 1000rpm, 10s; 4000rpm, 30s, 15 seconds before the end of the spin-coating process, use a 1ml pipette gun to measure 600ul of toluene as an anti-solvent, and quickly drop it on the rotating...

Embodiment 2

[0064] MA 0.88 DMA 0.07 Cs 0.05 PB 3 The preparation method of perovskite thin film, concrete steps are:

[0065]Take by weighing methyl ammonium iodide 0.1819g (MAI, 1.144mmol), dimethyl ammonium iodide 0.0157g (DMAI, 0.091mmol), cesium iodide 0.0169g (CsI, 0.065mmol) and lead iodide 0.5993g (1.3 mmol) was added to a 4ml glass bottle containing 1ml DMF and DMSO mixed reagent (volume ratio 4:1), stirred at 70°C for 1 hour, cooled, and filtered with a 0.22um polytetrafluoroethylene filter head After filtering, the resulting solution is a perovskite precursor solution. Place the nickel oxide substrate on the spin coater, drop the perovskite precursor solution on the nickel oxide substrate with a 200ul pipette gun, close the lid, and start spin coating. The spin coating parameters are 1000rpm, 10s; 4000rpm, 30s, 15 seconds before the end of the spin-coating process, use a 1ml pipette gun to measure 600ul of toluene as an anti-solvent, and quickly drop it on the rotating subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com