Acrylic resin coating material, preparation and application in aluminum profile

A technology of acrylic resin and methacrylic acid, applied in the direction of coating, etc., can solve the problems of environmental protection, etc., and achieve the effects of fast drying speed, excellent film-forming performance, excellent wear resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

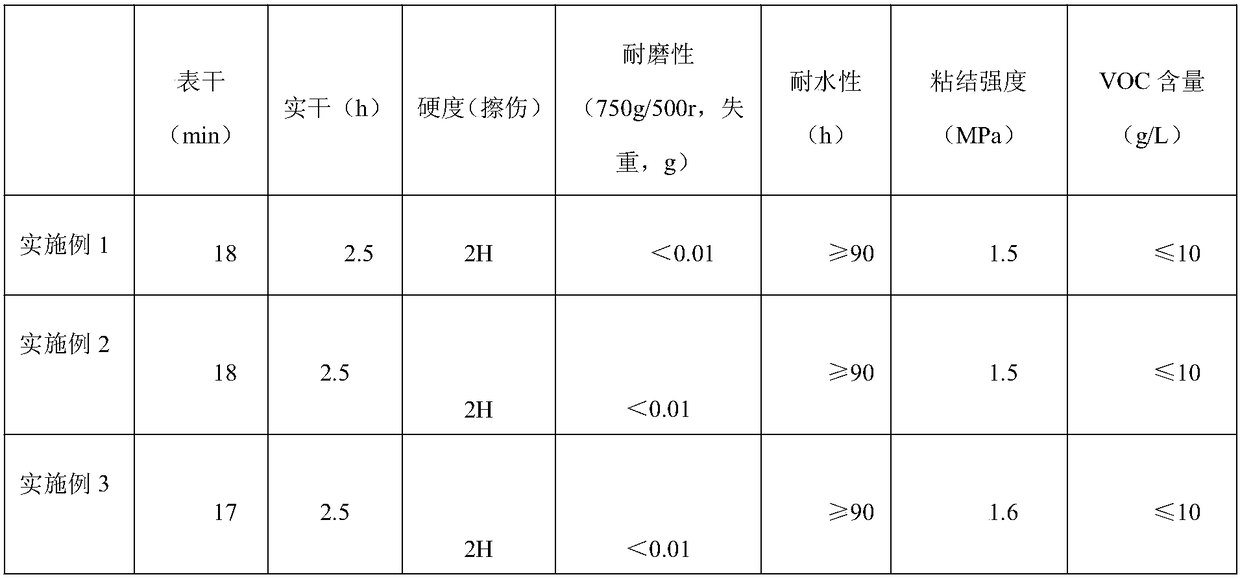

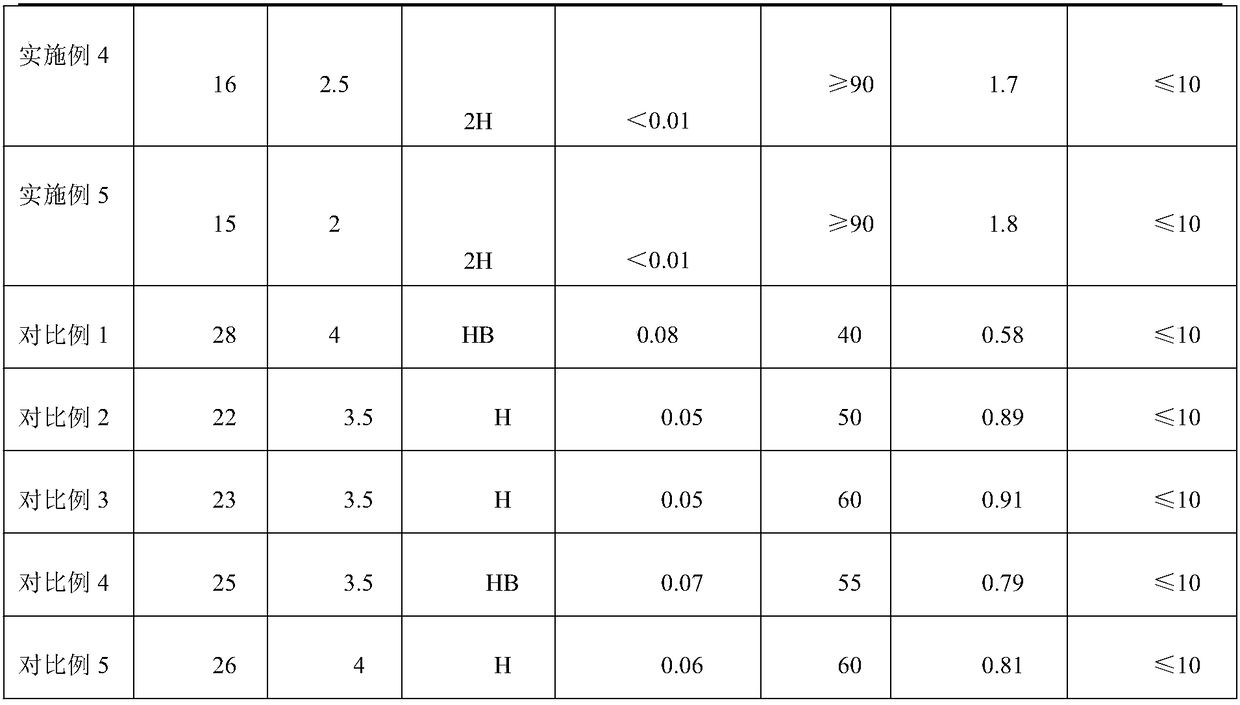

Examples

Embodiment 1

[0029] A preparation method for acrylic resin paint, comprising the steps of:

[0030] (1) Butyl methacrylate, isooctyl acrylate, glycidyl methacrylate, methacrylic acid and dicyclohexylmethane-4,4'-diisocyanate, vinyltriethoxysilane, 3-amino Mix propyltrimethoxysilane evenly, then drop it into deionized water at a constant speed, control the dropping time for 30 minutes, stir, ultrasonically oscillate, add the initiator, heat to 70°C under nitrogen atmosphere, keep it warm for 1 hour, and continue heating to 80°C, keep warm for 2 hours, and cool to room temperature to obtain a modified acrylic emulsion, which is set aside;

[0031] (2) Put the diphenyl ether formaldehyde resin and sucrose polyester into the reaction kettle, add deionized water and sodium dodecylbenzenesulfonate, heat to 85°C, stir and emulsify for 1 hour to obtain modified diphenyl ether Formaldehyde resin, spare;

[0032] (3) Deionized water, modified acrylic emulsion, modified diphenyl ether formaldehyde ...

Embodiment 2

[0043] A preparation method for acrylic resin paint, comprising the steps of:

[0044](1) Butyl methacrylate, isooctyl acrylate, glycidyl methacrylate, methacrylic acid and dicyclohexylmethane-4,4'-diisocyanate, vinyltriethoxysilane, 3-amino Propyltrimethoxysilane is mixed evenly, then dropped into deionized water at a constant speed, the dropping time is controlled at 50 minutes, stirred, ultrasonically oscillated, and the initiator is added, heated to 75°C under a nitrogen atmosphere, kept for 2 hours, and continued to heat to 85°C, keep warm for 3 hours, and cool to room temperature to obtain a modified acrylic emulsion, which is set aside;

[0045] (2) Put the diphenyl ether formaldehyde resin and sucrose polyester into the reaction kettle together, add deionized water and sodium dodecylbenzenesulfonate, heat to 95°C, stir and emulsify for 2 hours to obtain modified diphenyl ether Formaldehyde resin, spare;

[0046] (3) Deionized water, modified acrylic emulsion, modifie...

Embodiment 3

[0057] A preparation method for acrylic resin paint, comprising the steps of:

[0058] (1) Butyl methacrylate, isooctyl acrylate, glycidyl methacrylate, methacrylic acid and dicyclohexylmethane-4,4'-diisocyanate, vinyltriethoxysilane, 3-amino Mix propyltrimethoxysilane evenly, then drop it into deionized water at a constant speed, control the dropping time for 30 minutes, stir, ultrasonically oscillate, add the initiator, heat to 75°C under nitrogen atmosphere, keep it warm for 1 hour, and continue heating to 85°C, heat preservation for 2 hours, and cool to room temperature to obtain a modified acrylic emulsion, which is set aside;

[0059] (2) Put the diphenyl ether formaldehyde resin and sucrose polyester into the reaction kettle, add deionized water and sodium dodecylbenzenesulfonate, heat to 95°C, stir and emulsify for 1 hour to obtain modified diphenyl ether Formaldehyde resin, spare;

[0060] (3) Deionized water, modified acrylic emulsion, modified diphenyl ether forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com