Method for producing pigskin gelatin by alkaline method

A technology for gelatin and pigskin is applied in the field of alkaline production of pigskin gelatin, which can solve the problems of low extraction efficiency, long time consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

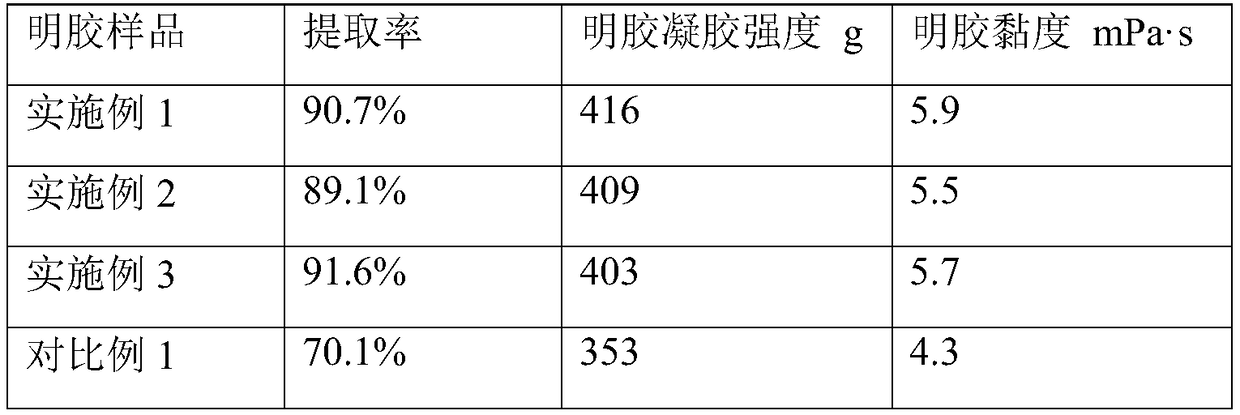

Examples

Embodiment 1

[0033] A method for producing gelatin by alkali method, the specific steps of the method are:

[0034] (1) Pigskin pretreatment: take fresh pigskin, depilate and cut the pigskin into small pieces of 2mm×2mm, soak the blocky pigskin in dodecylbenzenesulfonic acid with a concentration of 1.5% at 40°C Sodium solution for 3.0h, then fully wash with water to remove residual sodium dodecylbenzenesulfonate;

[0035] (2) Hot soaking: Soak the pigskin degreased in step (1) in hot water at 90°C for 6 hours, wherein the hot water needs to immerse the pigskin, filter, and then cool the pigskin to 10°C;

[0036] (3) Liming: Soak the pigskin obtained in step (2) with a concentration of 1% calcium hydroxide suspension, wherein the weight ratio of pigskin to calcium hydroxide suspension is 1:3, and the immersion time is 1d. Ash operation, let go of the old calcium hydroxide suspension, wash the pigskin with clean water, freeze the pigskin to -8°C, and then soak it in a calcium hydroxide susp...

Embodiment 2

[0049] A method for producing gelatin by alkali method, the specific steps of the method are:

[0050] (1) Pigskin pretreatment: take fresh pigskin, depilate and cut the pigskin into small pieces not larger than 2mm×2mm, soak the blocky pigskin in dodecylbenzene with a concentration of 1.5% at 48°C Sodium sulfonate solution for 3.0h, then fully wash with water to remove residual sodium dodecylbenzenesulfonate;

[0051] (2) Hot soaking: Soak the pigskin degreased in step (1) in hot water at 75°C for 8.5 hours, wherein the hot water needs to immerse the pigskin, filter, and then cool the pigskin to 10°C;

[0052] (3) Liming: Soak the pigskin obtained in step (2) with a concentration of 2% calcium hydroxide suspension, wherein the weight ratio of pigskin to calcium hydroxide suspension is 1:2, and the immersion time is 1d. Ash operation, let go of the old calcium hydroxide suspension, wash the pigskin with clean water, freeze the pigskin to -7°C, and then soak it in a calcium hy...

Embodiment 3

[0065] A method for producing gelatin by alkali method, the specific steps of the method are:

[0066] (1) Pigskin pretreatment: take fresh pigskin, depilate and cut the pigskin into small pieces of 1mm×1mm, soak the blocky pigskin in dodecylbenzenesulfonic acid with a concentration of 2.0% at 50°C Sodium solution for 2.0h, then fully wash with water to remove residual sodium dodecylbenzenesulfonate;

[0067] (2) Hot soaking: Soak the pigskin degreased in step (1) in hot water at 90°C for 6 hours, wherein the hot water needs to immerse the pigskin, filter, and then cool the pigskin to 5°C;

[0068] (3) Liming: Soak the pigskin obtained in step (2) with a concentration of 1.5% calcium hydroxide suspension, wherein the weight ratio of pigskin to calcium hydroxide suspension is 1:3, and the immersion time is 2 days. Ash operation, let go of the old calcium hydroxide suspension, wash the pigskin with clean water, freeze the pigskin to -5°C, and then soak it in a calcium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com